Cutter servo micro-feeding mechanism

A micro-feed and tool technology, applied in the direction of manufacturing tools, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems of asymmetric surface contour of parts, poor consistency of machining accuracy, low machining efficiency, etc., to improve the kinematic stiffness. , Improve the cutting rigidity, improve the effect of guiding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

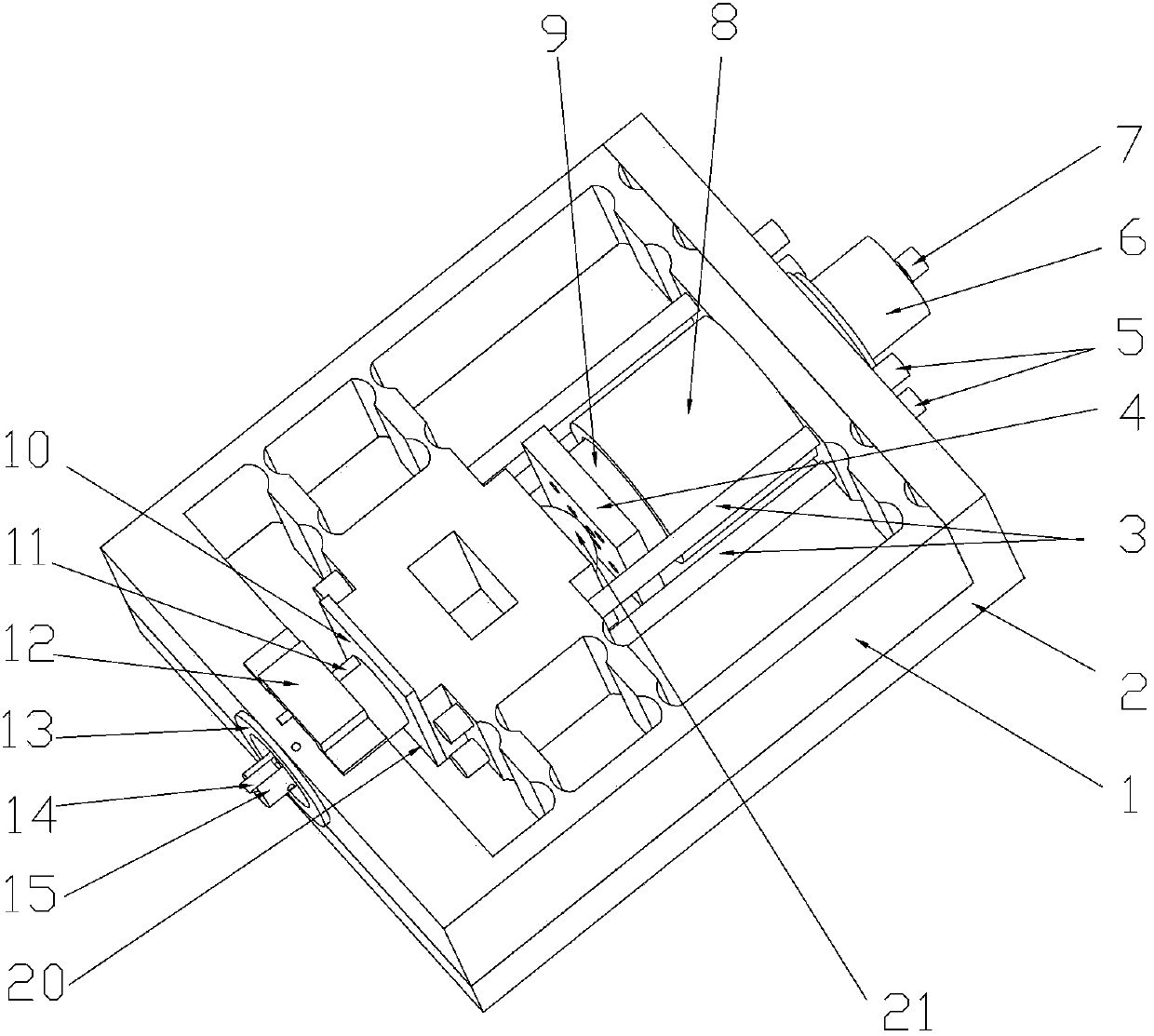

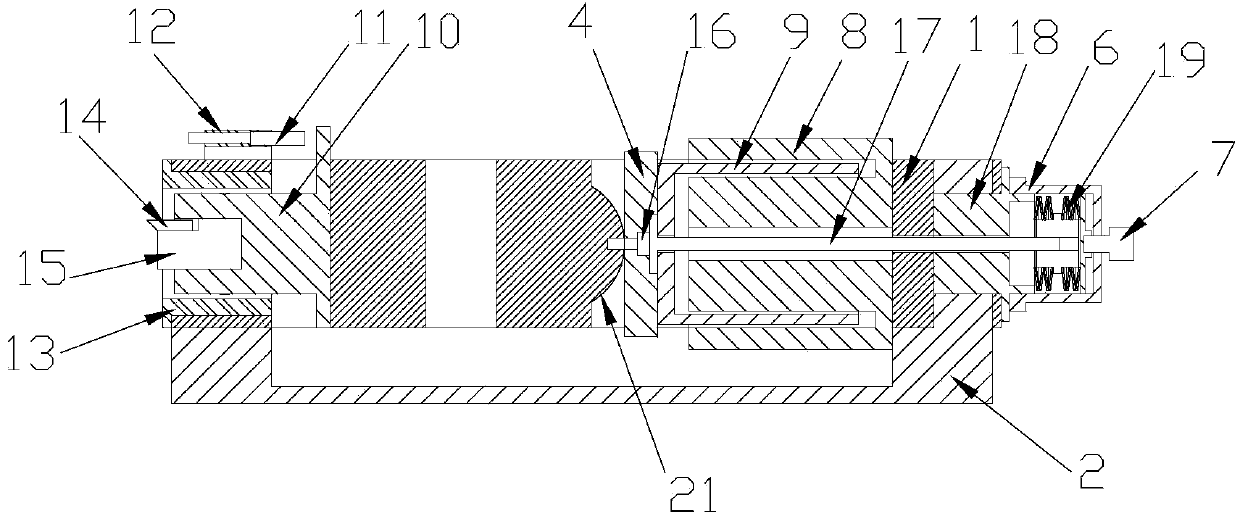

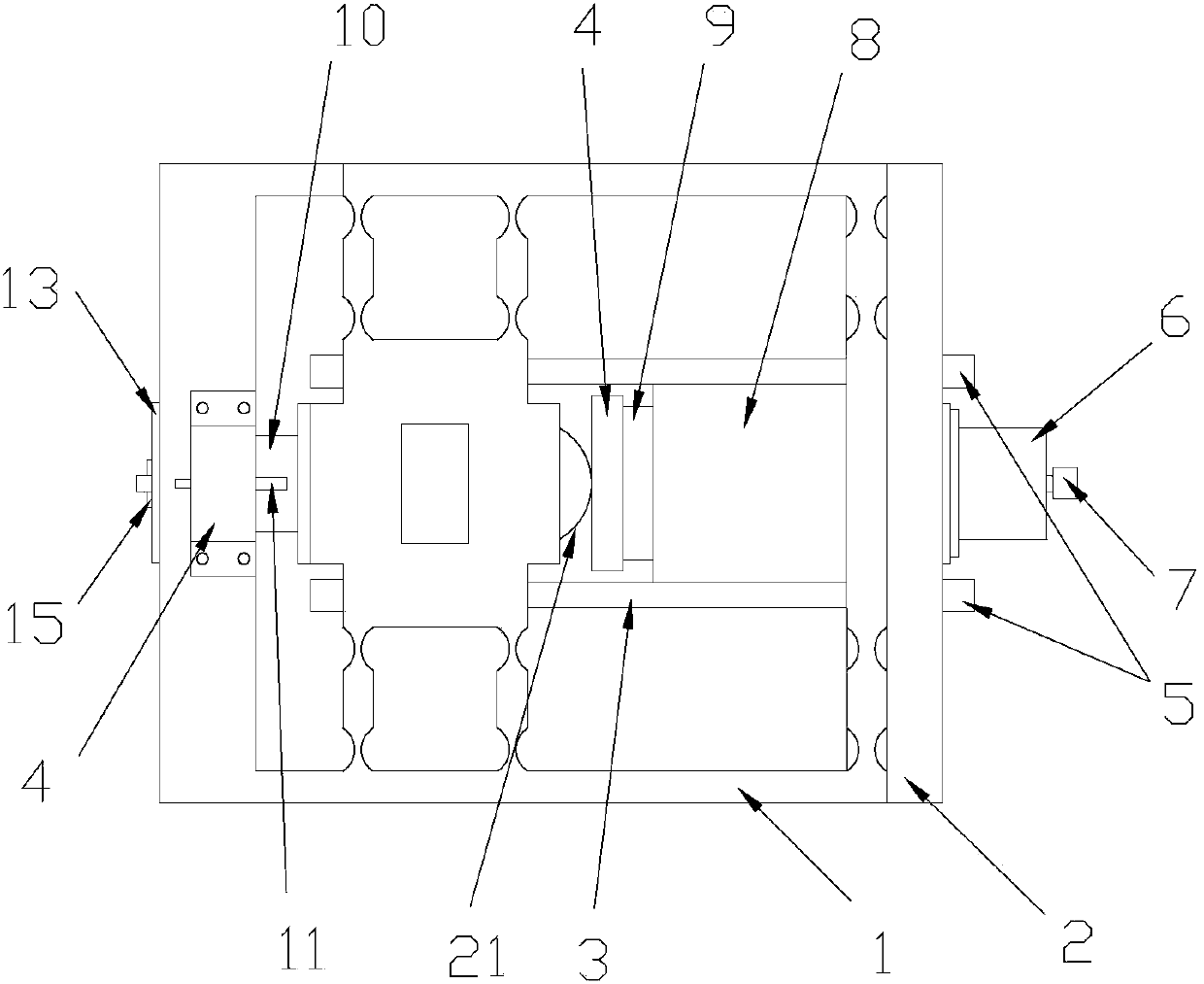

[0018] The following embodiments will further illustrate the present invention in conjunction with the drawings.

[0019] See Figure 1~3 , The embodiment of the present invention has a flexible hinge 1, a base 2, an elastic connecting rod 3, an adapter plate 4, an elastic connecting rod adjusting nut 5, an end cover 6, a spring adjusting nut 7, a voice coil motor stator 8, a voice coil motor Rotor 9, air static pressure guide inner rail 10, capacitive displacement sensor 11, sensor support frame 12, air static pressure guide outer rail 13, turning tool 14, cutter head clamp 15, tightening screw 16, drive shaft 17, pre-tightening nut 18 and disc spring 19.

[0020] The flexible hinge 1 is provided with an inner ring and an outer ring. The adapter plate 4 is fixed on the spherical part 21 of the inner ring of the flexible hinge 1 by a fastening screw 16. The adapter plate 4 is fixed with the voice coil motor rotor 9 and the voice coil motor stator 8 Fixed on the rear wall of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com