Carrier tape forming machine special for micro parts

A technology of miniature parts and forming machines, applied in belts, applications, household appliances, etc., can solve the problems of affecting production efficiency, slow manual inspection speed, and lack of inspection functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

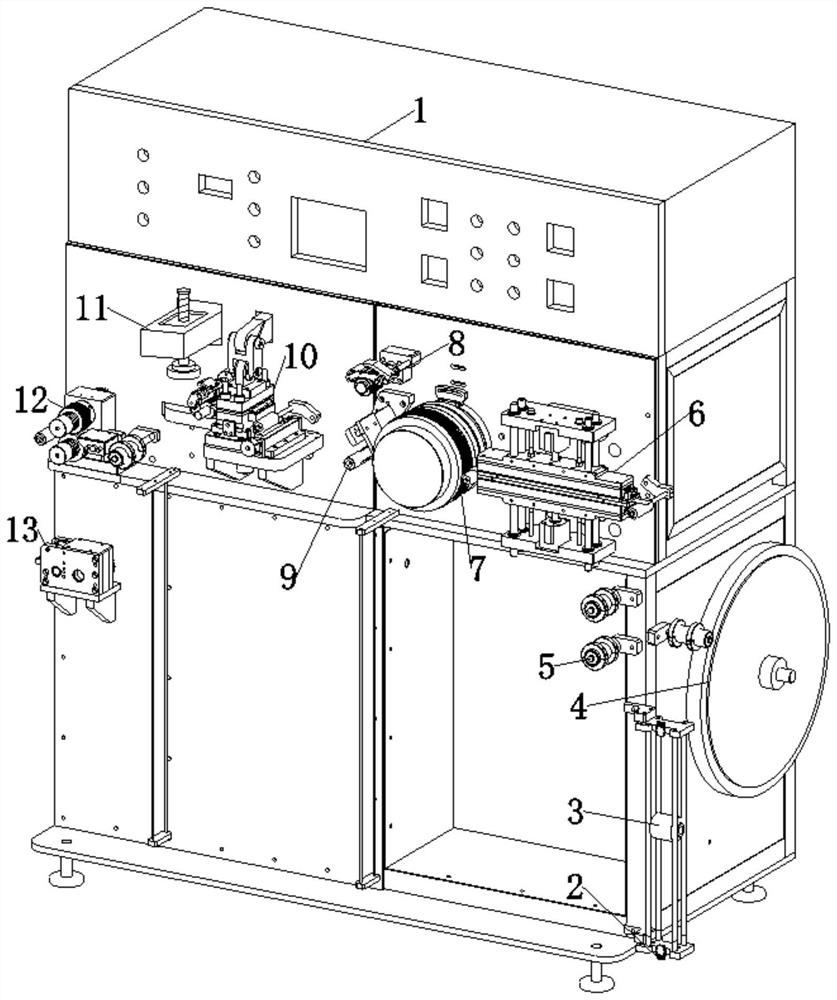

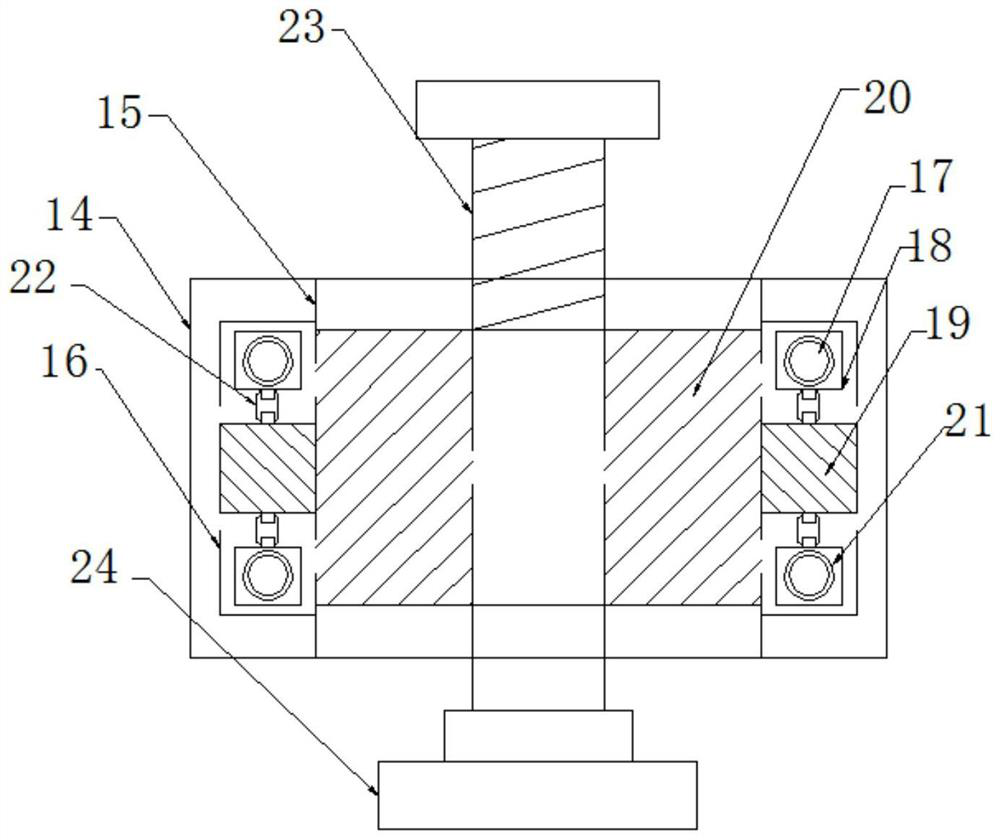

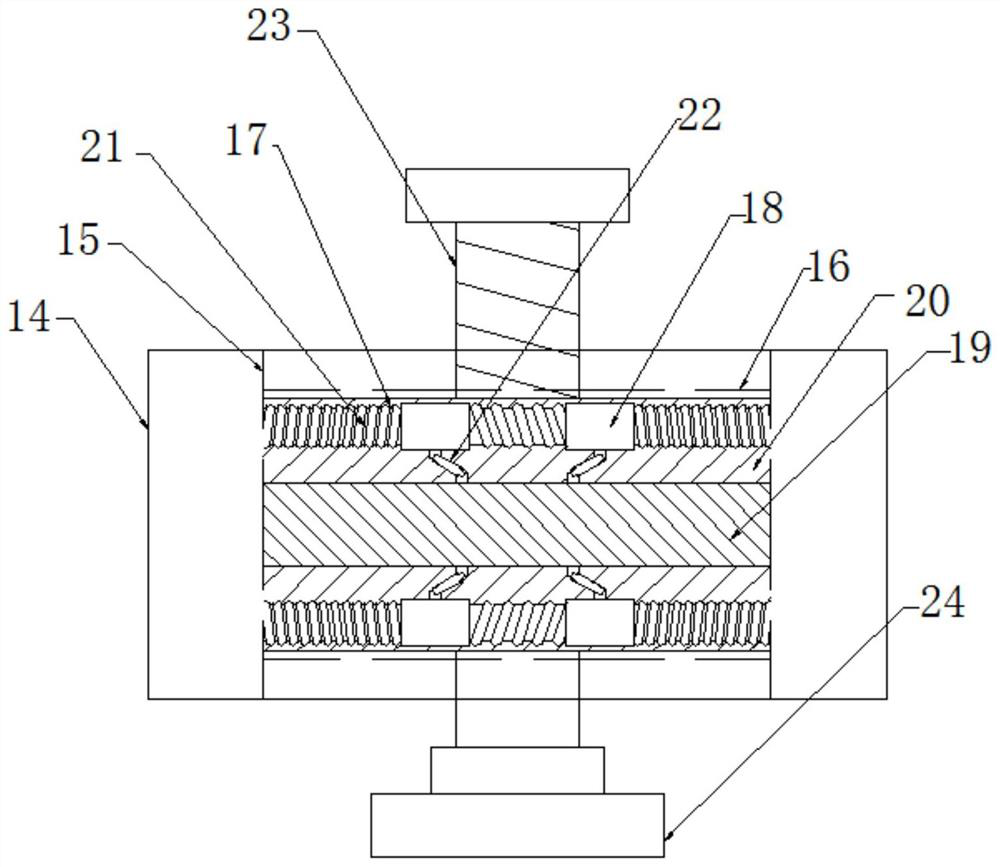

[0019] see Figure 1-3 , the present invention provides a technical solution: special carrier tape molding machine for micro parts, including electric control box 1, body, infrared heating device 6, forming mold 7, automatic demoulding device 8, demoulding auxiliary device 9, punching mold 10 , punching detection device 11, slitting module 12 and trimming material crushing device 13, the electric control box 1 is installed on the top of the body, and the right side wall of the body is sequentially installed with a discharge deceleration sensor from bottom to top 2. The unwinding tension device 3 and the sheet material unwinding device 4, a turning guide wheel 5 is installed on the lower right side of the front of the body, and the punching detection device 11 includes a support seat 14, a fixed seat 20, a limit seat 19, Guide rod 17, spring 21, slide block 18, connecting rod 22, adjusting stud 23, camera 24, punching detection device 11 can detect the punching size of the carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com