Casting core making material and core making method

A technology of core material and core bone, which is applied in the field of casting core materials, can solve problems such as high cost of modeling, mold clamping and grinding, difficulty in cleaning and grinding, and increased production hours, so as to reduce cleaning and grinding hours, save storage and Maintenance operation, the effect of improving product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The weight percentage composition of the foundry core material of embodiment 1 comprises: steel shot 60%, carbon particle 20%, in the present embodiment, take sawdust as carbon particle, the balance is silica sand, and wherein, the particle diameter of steel shot is 0.5~1.5 mm, the particle size of carbon particles <1.0 mm. The steel shot is recovered from the waste steel shot produced by the shot blasting machine, and the iron content of the waste steel shot is 92%, and the silica sand is recovered from the old sand produced by the shot blasting machine.

Embodiment 2

[0029] The weight percentage composition of the foundry core material of embodiment 2 comprises: steel shot 55%, carbon grain 25%, in the present embodiment, take carbon block particle as carbon grain, surplus is silica sand, and wherein, the particle diameter of steel shot is 0.5% ~1.5 mm, the particle size of carbon particles <1.0mm. The steel shot is recovered from the waste steel shot produced by the shot blasting machine. The iron content of the waste steel shot is 95%, and the weight of the 20-30 mesh steel shot in the waste steel shot is 55-65%; the silica sand recovery Old sand produced after shot blasting by shot blasting machine.

Embodiment 3

[0030] Embodiment 3, the core making method using the foundry core making material of embodiment 1 as raw material, comprises the following steps:

[0031] (1) Mix the raw materials of the core-making material evenly and add them to the sand mixer. After stirring well, add alkaline phenolic resin as an adhesive. The volume ratio of the added alkaline phenolic resin to the core-making material is 1.0: 20. Stir fully again to obtain the prepared iron sand;

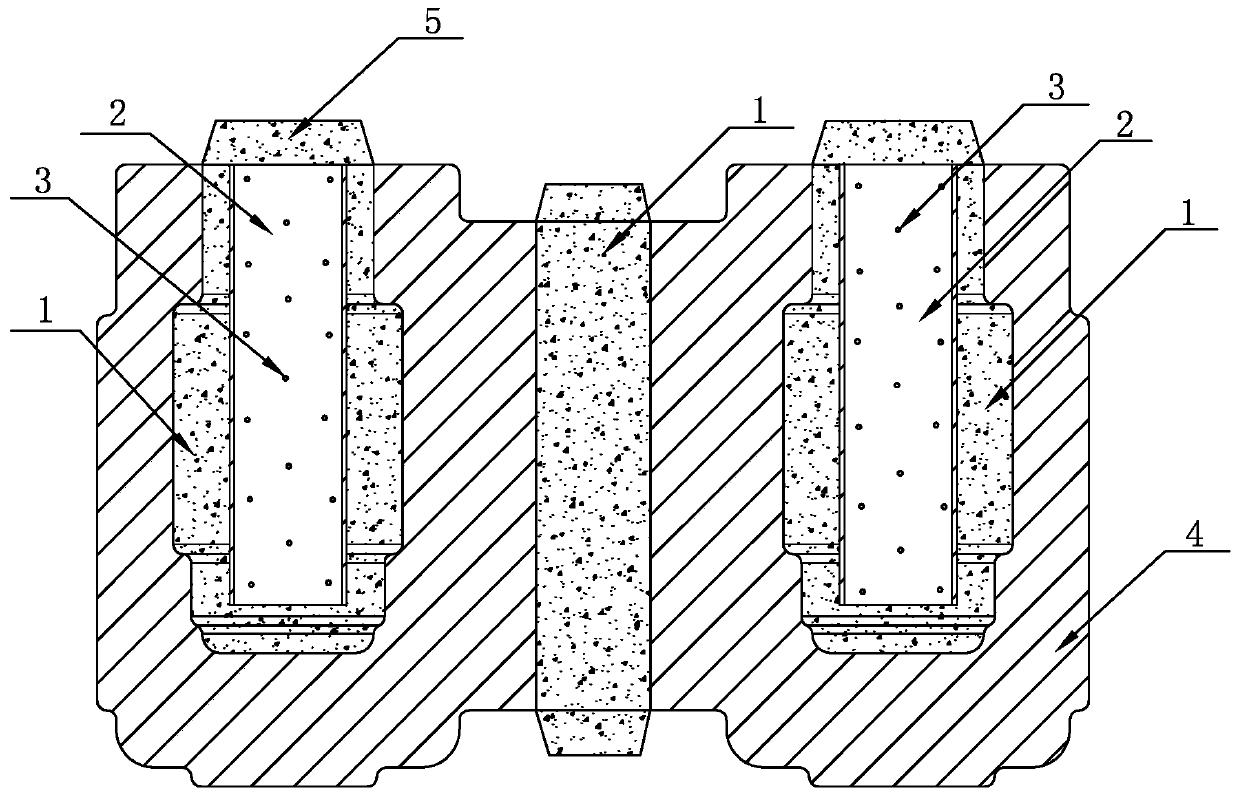

[0032] (2) Place the core bone in the core box, and the side wall of the core bone is pre-opened with multiple vent holes with a diameter > 10 mm. According to the shape of the casting, fill the prepared iron sand around the core bone and tamp it. The thickness of the iron sand filled between the outer surface of the bone and the inner surface of the core box is 35 mm;

[0033] (3) Continuous input of CO to multiple exhaust holes through the transmission conduit 2 Air for 10 minutes to harden the filled iron sand to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com