Ternary compound photocatalyst and preparation and application methods thereof

A photocatalyst, ternary composite technology, applied in catalyst activation/preparation, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc. Effects of interfacial electron transfer efficiency and excellent visible light water splitting for hydrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention provides a method for preparing the above-mentioned ternary composite photocatalyst, comprising: S1) mixing MOFs and noble metal salts in a first solvent, and then irradiating to obtain MOFs of composite noble metals; S2) mixing MOFs of the composite noble metals MOFs, sulfur sources and metal salts are mixed in a second solvent, and then irradiated to obtain a ternary composite photocatalyst.

[0037] The present invention has no special limitation on the sources of all raw materials, which can be commercially available.

[0038] Among them, the MOFs are preferably titanium-based organic framework materials, chromium-based organic framework materials and zirconium-based organic framework materials, more preferably MIL-125, MIL-125-NH 2 , MIL-101, UIO-66 and UIO-66-NH 2One of them; the MOFs are preferably prepared according to the following steps: mixing metal sources and organic ligands in a solvent, heating for solvothermal reaction, and obtaini...

Embodiment 1

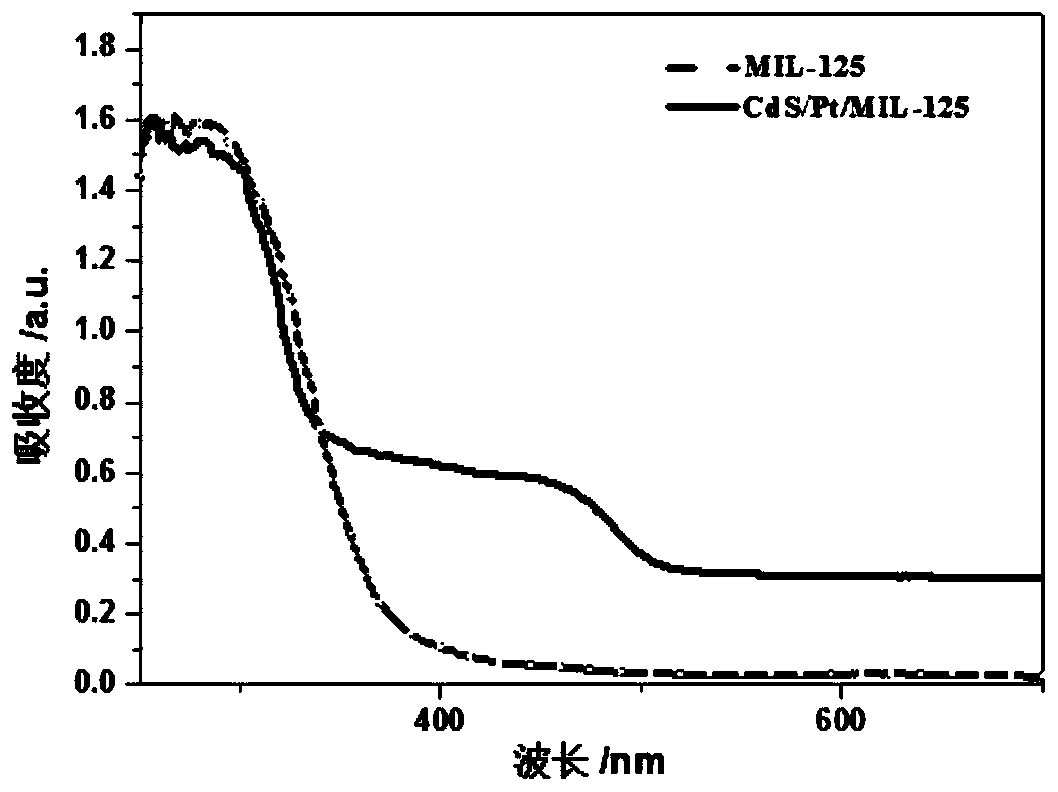

[0052] Take CdS / Pt / MIL-125 ternary composite photocatalyst as an example:

[0053] 1.1 Put a mixture of titanium isopropoxide (0.312mL), terephthalic acid (0.60g), 1.2mL methanol and 9mL N,N-dimethylformamide into a 25mL polytetrafluoroethylene liner and stir at room temperature After uniformity, it was sealed in a stainless steel autoclave and heated at 130°C for 15 hours. Finally, after natural cooling, they were washed with N,N-dimethylformamide, methanol and acetone respectively and centrifuged, the white powder was collected by filtration, and dried in vacuum at 50°C for 12 hours to obtain MIL-125.

[0054] 1.2 Disperse 40 mg of the MIL-125 obtained in 1.1 in 10 mL containing 1.5 mg K 2 PtCl 4 After ultrasonic treatment for 10 minutes at room temperature, the glass bottle containing the mixed solution was further stirred for 24 hours; the impregnated MIL-125 sample was obtained by centrifugation; and the impregnated sample was dispersed by ultrasonic treatment for 10 mi...

Embodiment 2

[0061] The ternary composite photocatalyst was prepared in the same manner as in Example 1 except that the content of supported noble metal was changed.

[0062] When 40mg of MIL-125 is dispersed in 10mL containing 3mg K 2 PtCl 4 In absolute ethanol solution, the hydrogen production efficiency of the obtained CdS / Pt / MIL-125 ternary composite photocatalyst was 832.03μmol·g -1 h -1 .

[0063] When 40mg of MIL-125 is dispersed in 10mL containing 0.5mg K 2 PtCl 4 In absolute ethanol solution, the hydrogen production efficiency of the obtained CdS / Pt / MIL-125 ternary composite photocatalyst was 1596.37μmol·g -1 h -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com