A method and application of non-roasting preparation of phosphorus-containing wastewater adsorbent from aluminum-containing waste slag

An aluminum waste residue, no roasting technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc. The effect is not ideal, the effect of avoiding land occupation and environmental pollution, and avoiding energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] according to figure 1 A method for producing phosphorus-containing wastewater adsorbent without roasting aluminum-containing waste slag includes the following steps:

[0045] Step 1: Prepare aluminum-containing water

[0046] Adding the aluminum slag to the hydrochloric acid solution, stirring at room temperature, standing for reaction, and obtaining the supernatant for later use;

[0047] Step 2: Granulation

[0048] The aluminum sludge, the cement-based grouting material and the aluminum-containing water prepared in step 1 are evenly mixed and then granulated;

[0049] Step 3: Conservation

[0050] The granulated product in step 2 is sprayed with water for curing, and the preparation process is completed after it solidifies.

[0051] In actual use, the present invention uses aluminum sludge and aluminum waste slag as raw materials to prepare the phosphorus removal adsorbent, which has a wide source of raw materials and a simple preparation process, which avoids la...

Embodiment 2

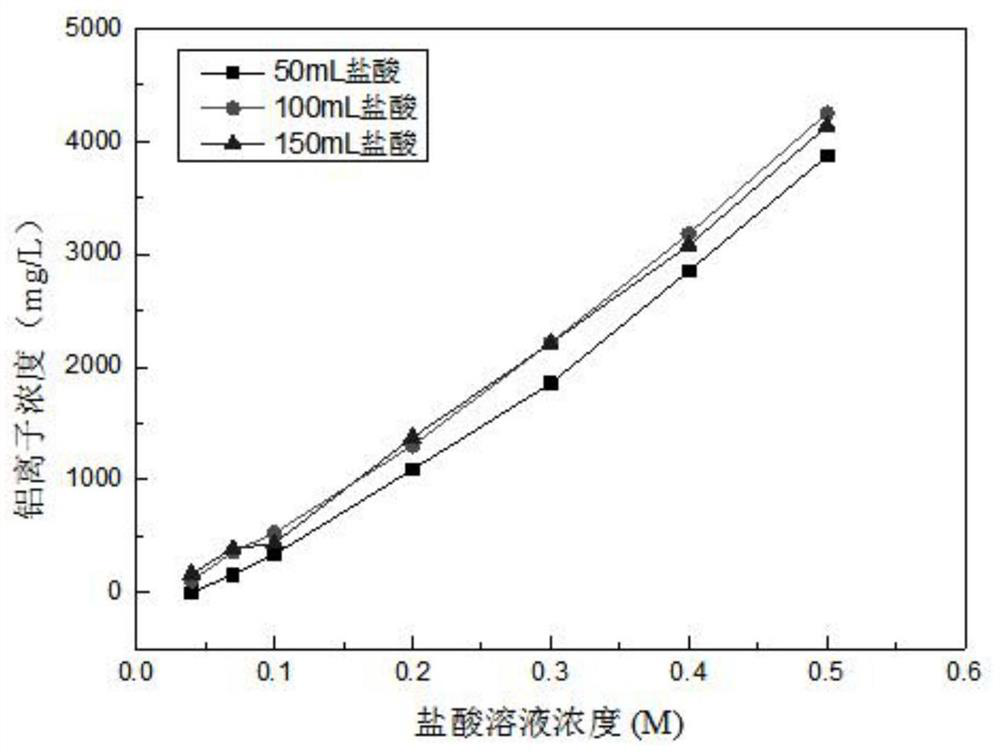

[0053] according to figure 1 A method for producing phosphorus-containing wastewater adsorbent without roasting aluminum-containing waste slag shown is different from Example 1 in that the molar concentration of the hydrochloric acid solution used in the step 1 is 0.04-0.5M, and the aluminum slag The mass volume ratio with hydrochloric acid solution is 1g:10mL~30mL.

[0054] Preferably, the molar concentration of the hydrochloric acid solution used in the step 1 is 0.5M, and the mass volume ratio of the aluminum slag to the hydrochloric acid solution is 1g:30mL.

[0055] In actual use, by adopting the technical scheme, the reaction between hydrochloric acid and aluminum slag is sufficient, and the prepared aluminum-containing water is used in the subsequent process, and the effect is better.

Embodiment 3

[0057] according to figure 1 The shown method for producing phosphorus-containing wastewater adsorbent without roasting aluminum-containing waste slag is different from Example 1 in that the standing reaction time in Step 1 is 12-24 hours.

[0058] In actual use, this technical scheme is adopted for the standing reaction time in step 1, which ensures a relatively high aluminum concentration of the prepared aluminum-containing water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com