Continuous flow photochemical reactor

A chemical reactor and photochemical reaction technology, applied in the field of photochemical reaction, can solve the problems of difficult to realize industrial production, low product output, many side reactions, etc., and achieve the effect of improving utilization rate, reducing device volume and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

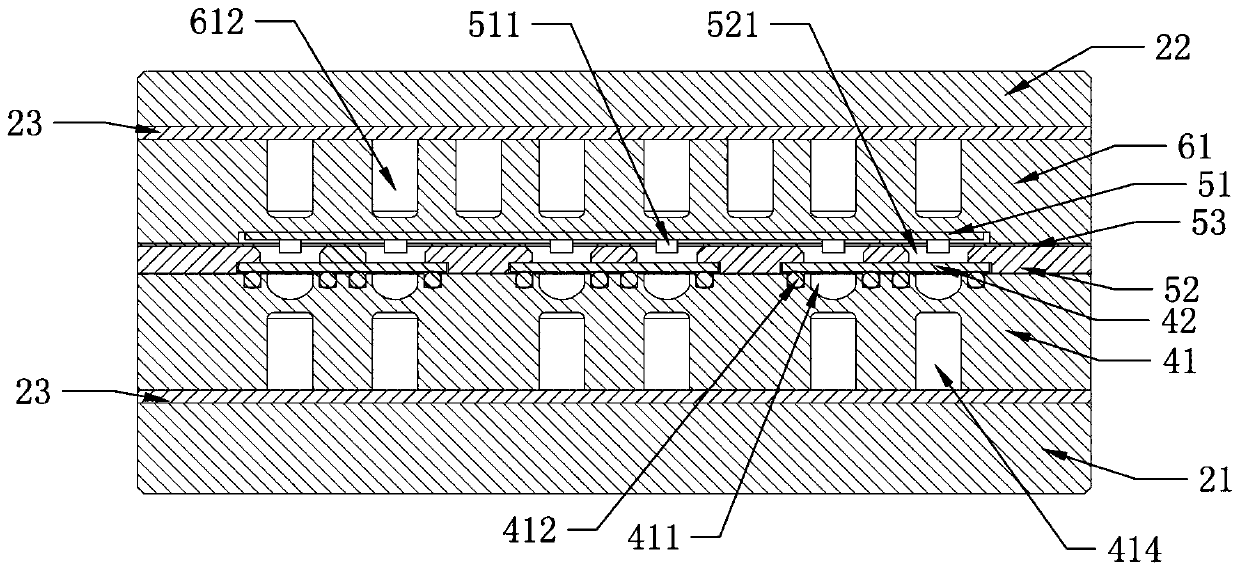

[0041] This embodiment provides a compact continuous flow photochemical reactor, which includes a reaction chamber 1 for performing photochemical reactions, a temperature control chamber for controlling the temperature of the reaction chamber 1, and a light source control chamber for regulating the light source. Such as figure 1 and Figure 6 As shown, the reaction chamber 1 includes a housing and a reactor module 2 located inside the housing. The reactor module 2 includes a photochemical reaction unit 4, a light source module 5 arranged outside the photochemical reaction unit, a light source heat dissipation module, and a reactant Temperature control module.

[0042] Such as Figure 1-2 As shown, the reactor module 2 includes a reaction chamber plate 41 , a quartz glass plate 42 , a quartz plate fixing cover plate 52 , a thermal insulation pad 53 , and a light source plate 51 which are stacked in sequence. The reaction chamber plate 41 and the light source plate 51 are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com