Tool cartridge

A tool box and tool technology, which is applied in the field of tool boxes, can solve problems such as fretting corrosion and die sagging, and achieve the effect of reducing elastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

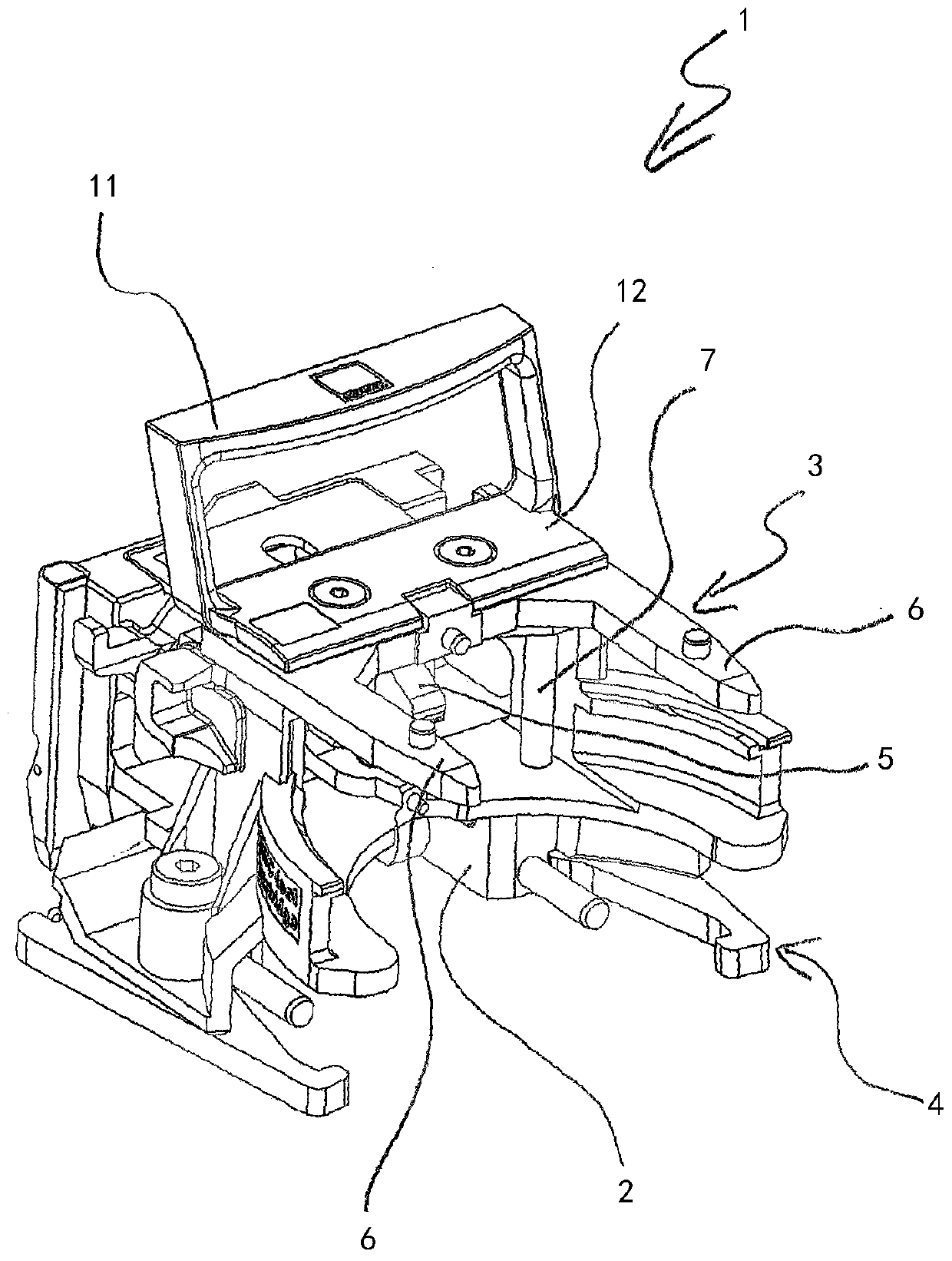

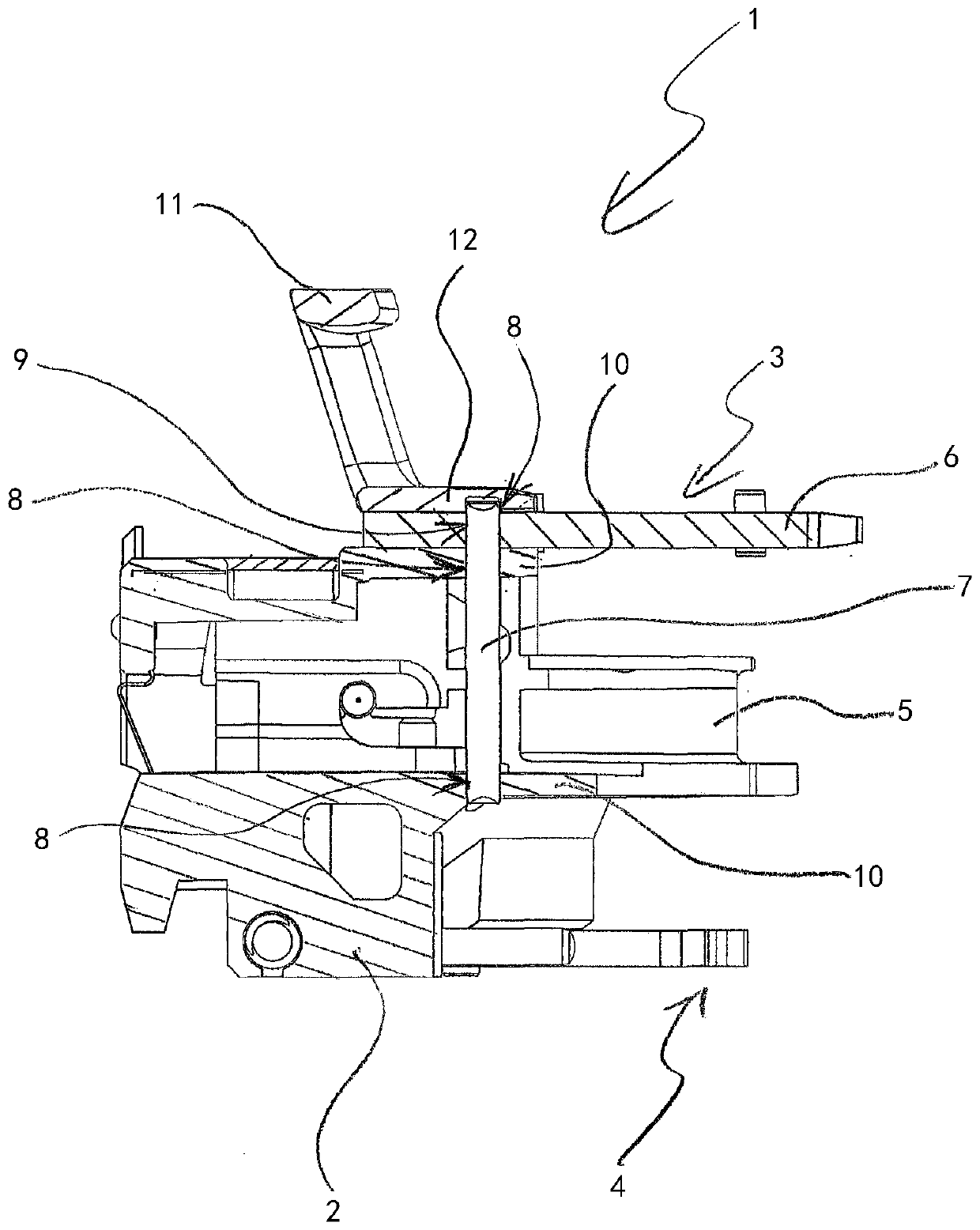

[0024] figure 1 shows a perspective view of a kit 1 according to the invention, figure 2 A side sectional view of a tool box 1 according to the invention is shown.

[0025] The tool box 1 is used to accommodate a multi-part processing tool (not shown) for processing plate-like workpieces. The tool box 1 comprises a box base 2 . A die holder 3 configured as a tool part of a processing die for detachably holding the processing tool and a die holder 4 configured as a processing die for detachably holding the processing tool are arranged on the cassette base body 2 . Furthermore, a holder 5 for a stripper of the processing tool, preferably suitable for processing plate-like workpieces, is provided. Alternatively, embodiments are also possible in which this holder 5 is not provided, since there are handling tools that do not have any stripper.

[0026] The die holder 3 comprises two box arms 6 . The cartridge arms 6 are pivotable relative to each other and are correspondingly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com