A method of manufacturing an embedded flexible conductive circuit

A technology of flexible conduction and manufacturing methods, which is applied in printed circuit manufacturing, cleaning methods using liquids, printed circuits, etc., can solve the problems of poor flexibility of conductive lines, poor electrical conductivity, and complicated manufacturing processes, and achieve low cost and solve integrated problems. The effect of poor performance and easy effective integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

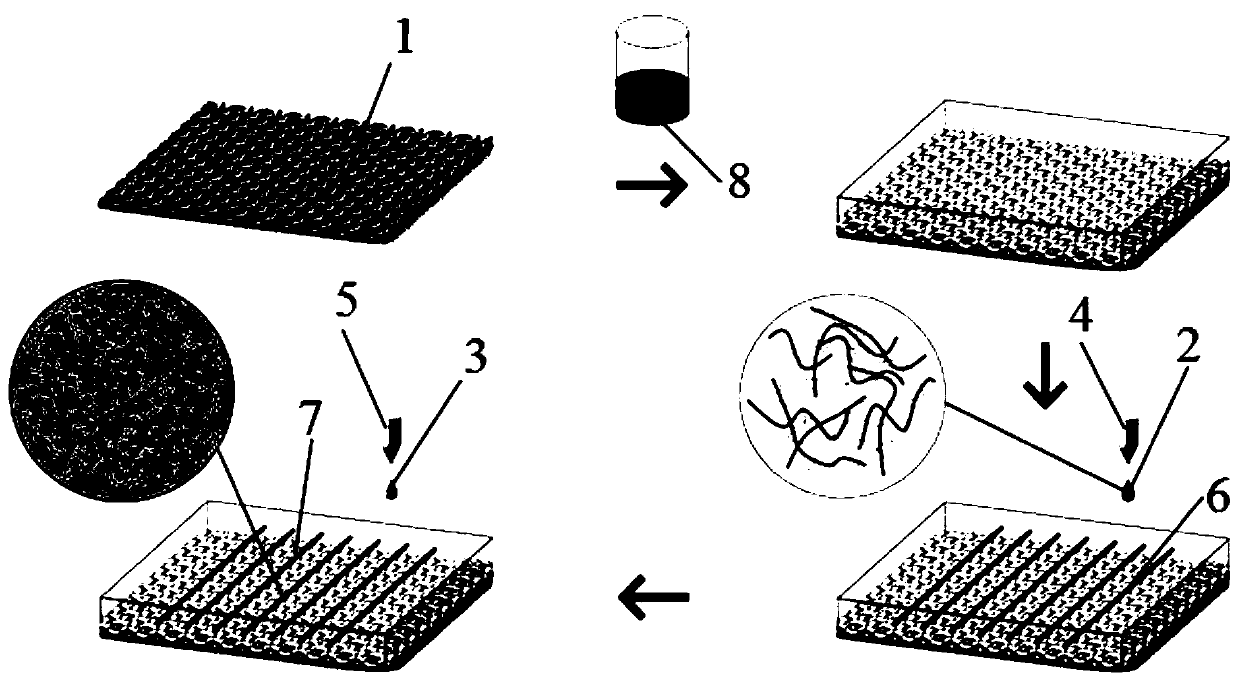

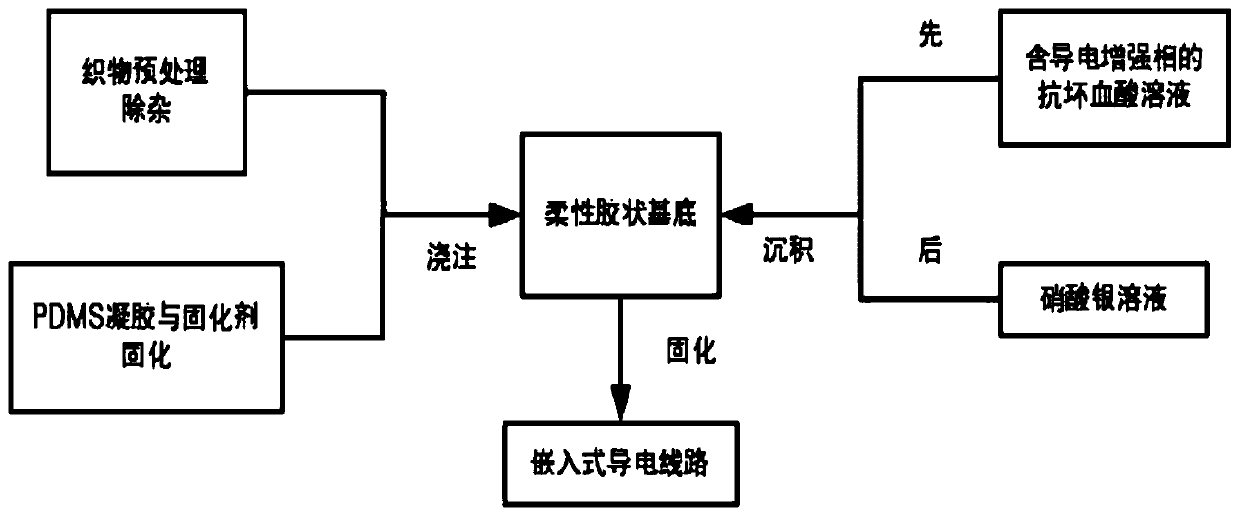

[0049] (1) Preparation of flexible substrate 1

[0050] Select a piece of paper, i.e. the flexible substrate 1, and cut it into a size of 70mm×70mm for later use;

[0051] Stir polydimethylsiloxane and Dow Corning 184 silicone rubber curing agent at a mass ratio of 9:1, and use a vacuum filter to remove air bubbles to obtain packaging material 8, which is placed on the upper surface of the flexible substrate 1 Pouring encapsulation material 8 to completely cover;

[0052] (2) Preparation of Ink A2

[0053] Dissolve ascorbic acid powder, polyvinylpyrrolidone, silver nanowires, carbon nanotubes and graphene in deionized water at a mass ratio of 280:70:5:2:1, and stir evenly to obtain a precursor solution; Ink A2 is obtained after supersonicating the precursor solution in an ultrasonic oscillator for 1 hour, and is ready for use; wherein, the mass volume concentration of ascorbic acid powder is 20% w / v, the mass volume concentration of nano-silver is 0.1% w / v, and the carbon na...

Embodiment 2

[0059] (1) Preparation of flexible substrate 1

[0060] Select the plain weave fabric in the textile material, that is, the flexible substrate 1, cut it into a size of 70mm×70mm, soak it in alcohol with a volume fraction of 75%, and test it in an ultrasonic oscillator with a frequency of 40KHz and a power of 70W. Sonicate for 15 minutes, wash it with deionized water, let it stand at room temperature for 0.8 hours, and set aside;

[0061] Stir polydimethylsiloxane and Dow Corning 184 silicone rubber curing agent evenly at a mass ratio of 10:1, and use a vacuum filter to remove air bubbles to obtain packaging material 8, which is placed on the upper surface of the flexible substrate 1 Pouring encapsulation material 8 to completely cover;

[0062] (2) Preparation of Ink A2

[0063] Dissolve ascorbic acid powder, polyvinylpyrrolidone, silver nanowires, carbon nanotubes and graphene in deionized water at a mass ratio of 300:80:10:3:1, and stir evenly to obtain a precursor solutio...

Embodiment 3

[0069] (1) Preparation of flexible substrate 1

[0070] Select polyimide, i.e. the flexible substrate 1, and cut it into a size of 70mm×70mm for later use;

[0071] Stir polydimethylsiloxane and Dow Corning 184 silicone rubber curing agent evenly at a mass ratio of 15:1, and use a vacuum filter to remove air bubbles to obtain packaging material 8, which is placed on the upper surface of the flexible substrate 1 Pouring encapsulation material 8 to completely cover;

[0072] (2) Preparation of Ink A2

[0073] Dissolve ascorbic acid powder, polyvinylpyrrolidone, silver nanowires, carbon nanotubes and graphene in deionized water at a mass ratio of 350:90:15:8:1, and stir evenly to obtain a precursor solution; Ink A2 is obtained after supersonicating the precursor solution in an ultrasonic oscillator for 2 hours, and is ready for use; wherein, the mass volume concentration of ascorbic acid powder is 30% w / v, the mass volume concentration of nano-silver is 1% w / v, and the carbon n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com