Novel nano temperature testing material preparation method

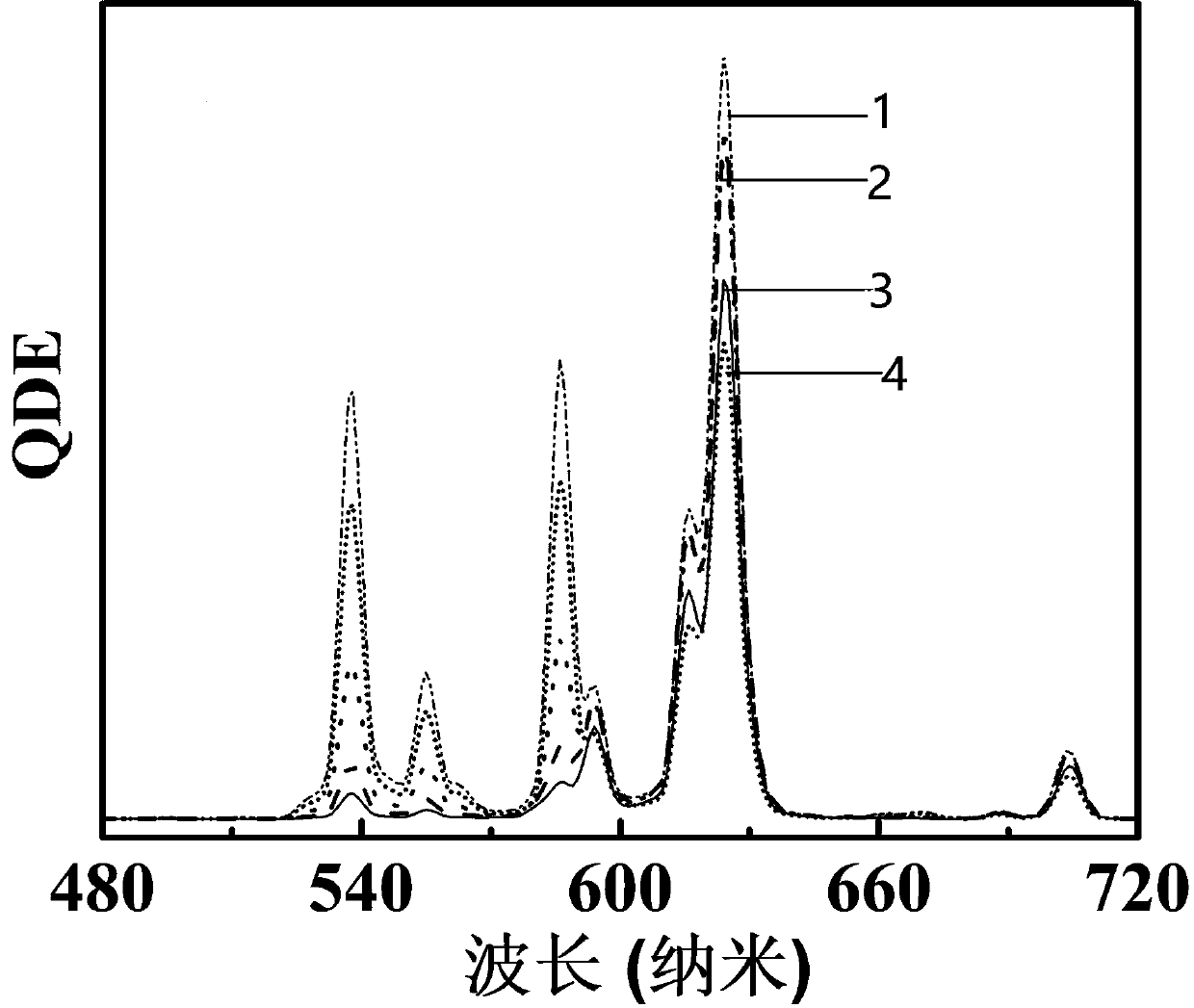

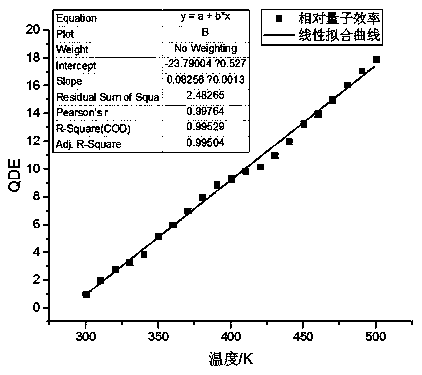

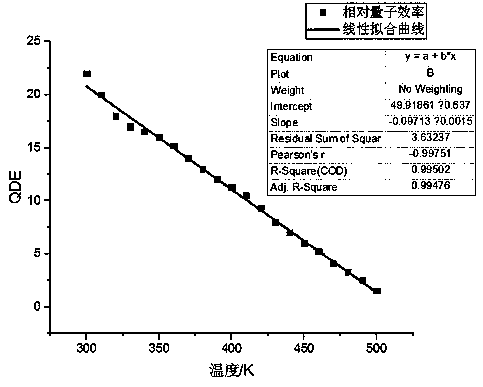

A nano and new technology, applied in the preparation and application of light-excited luminescent materials, can solve the problems of complex measurement methods, difficult industrialization, high equipment cost, etc., and achieve the effect of realizing response efficiency, fast and accurate visualization of temperature sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 7.00g of lanthanum oxide, 2.00g of neodymium oxide, and 1.00g of dysprosium oxide into a beaker, add 10mL of 36% dilute nitric acid solution, stir and dissolve at room temperature, and heat each solution on an electric furnace after the dissolution is completed. Crystallize, evaporate excess nitric acid solution, then add 100mL deionized water to dilute into a neutral solution, then mix the three solutions and add 1.00g of EDTA, stir well and place in a reactor at 80°C to stir for 4 hours; react After completion, wash 7 times with deionized water, then use a centrifuge to separate the solid powder and then place it in a vacuum oven and dry it at 80°C for 3 hours. After the drying is completed, add sodium fluoride flux with a weight ratio of 3.00g, and ball mill it evenly Then put it in the atmosphere reaction furnace, adjust the inert gas N 2 and reducing gas H 2 The feeding rate is 3:1, react at 100°C for 3 hours; after the reaction is completed, soak the powder...

Embodiment 2

[0029] Weigh 7.00g of gadolinium oxide, 2.00g of praseodymium oxide, and 1.00g of europium oxide into a beaker, add 15mL of 36% dilute nitric acid solution, stir and dissolve at room temperature, and heat each solution on an electric furnace after the dissolution is completed. Crystallize, evaporate excess nitric acid solution, then add 80mL deionized water to dilute into neutral solution respectively, then add 1.00gEDTA after the three kinds of solutions are mixed, stir and put in the reaction kettle under 80 ℃ and stir for 5 hours; react After completion, wash with deionized water 5 times, then use a centrifuge to separate the solid powder and then place it in a vacuum oven and dry it at 80°C for 5 hours. After the drying is completed, add sodium fluoride flux with a weight ratio of 3.50g, and ball mill it evenly Then put it in the atmosphere reaction furnace, adjust the inert gas N 2 and reducing gas H 2 The feeding rate is 3:1, react at 200°C for 3 hours; after the reacti...

Embodiment 3

[0031] Weigh 5.00g of lanthanum oxide, 2.00g of yttrium oxide, 1.50g of praseodymium oxide, 0.50g of bismuth oxide, 0.60g of europium oxide, and 0.40g of samarium oxide and place them in a beaker, add 10mL of 36% dilute nitric acid solution, and stir at room temperature Dissolve, after the dissolution is completed, place each solution on an electric furnace to heat and crystallize, evaporate the excess nitric acid solution, then add 100mL deionized water to dilute into a neutral solution, then mix the three solutions and add 1.00g EDTA, stir evenly and place Stir and react in the reactor at 80°C for 3 hours; wash with deionized water 7 times after the reaction is completed, then use a centrifuge to separate the solid powder and place it in a vacuum oven to dry at 80°C for 3 hours. Add sodium fluoride flux with a weight ratio of 5.00g, put it in the atmosphere reaction furnace after ball milling, and adjust the inert gas N 2 and reducing gas H 2 The feeding rate is 3:1, react ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com