Vibration auxiliary roller type magnetorheological polishing device and method

A technology of magnetorheological polishing and auxiliary rollers, which is applied in the direction of grinding drive devices, grinding/polishing equipment, and parts of grinding machine tools, can solve the problems of low polishing efficiency, improve polishing efficiency, facilitate heat dissipation, and save energy cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

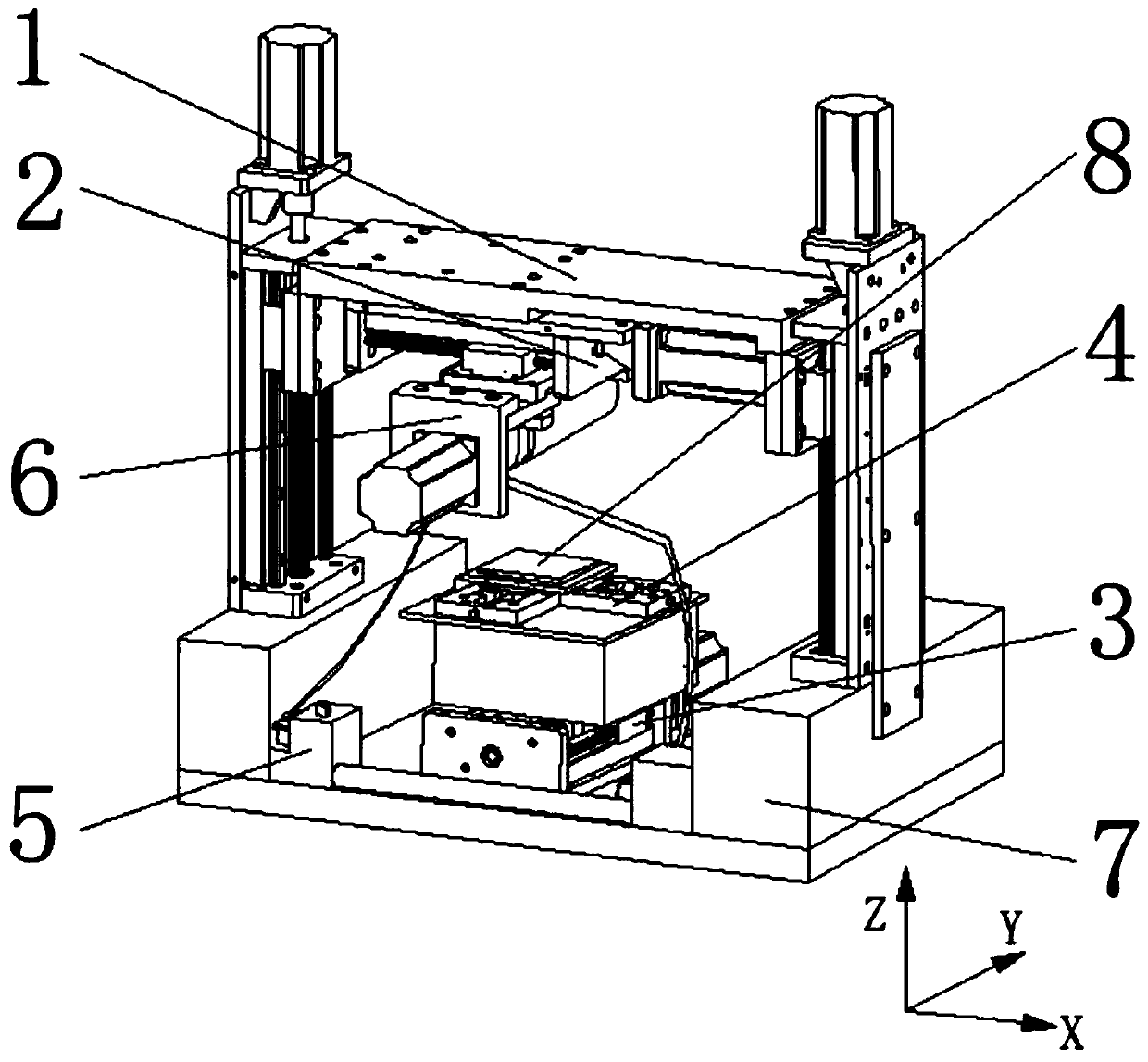

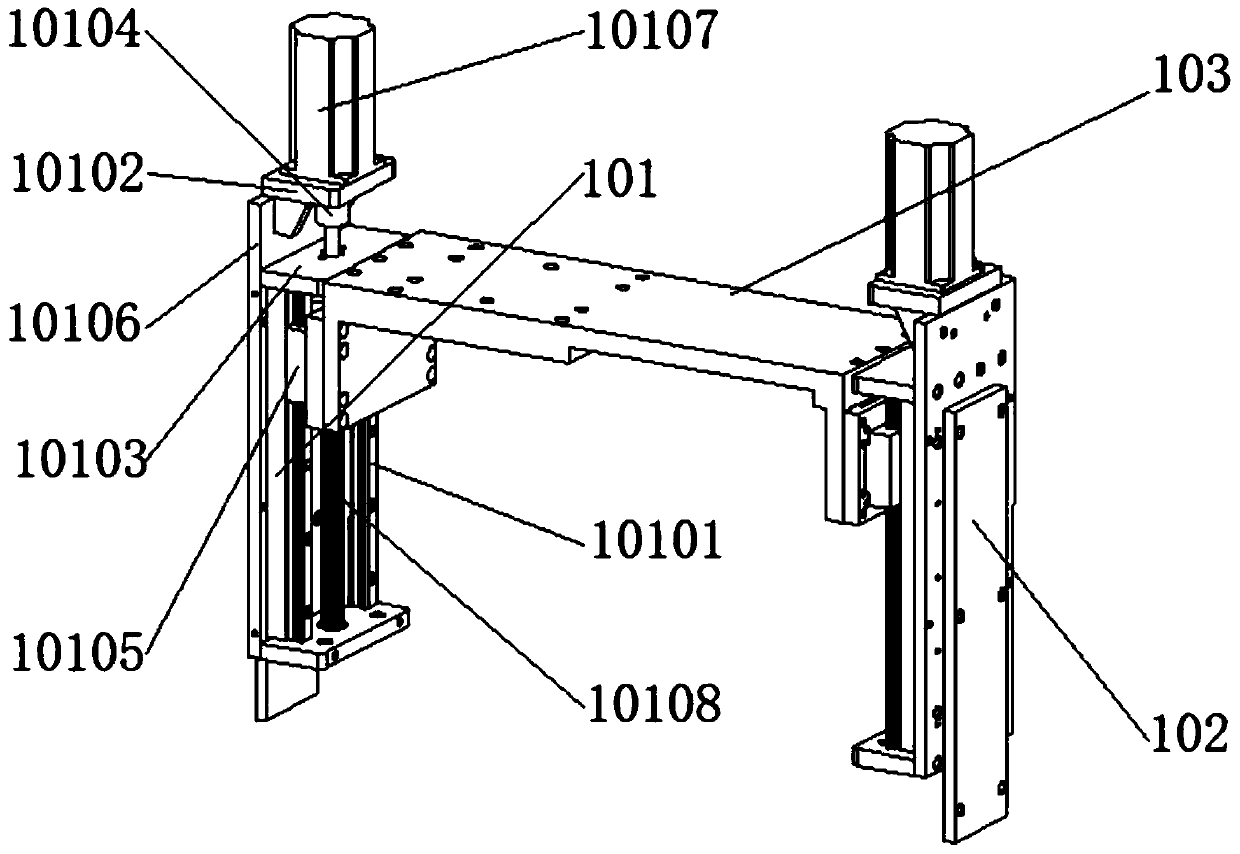

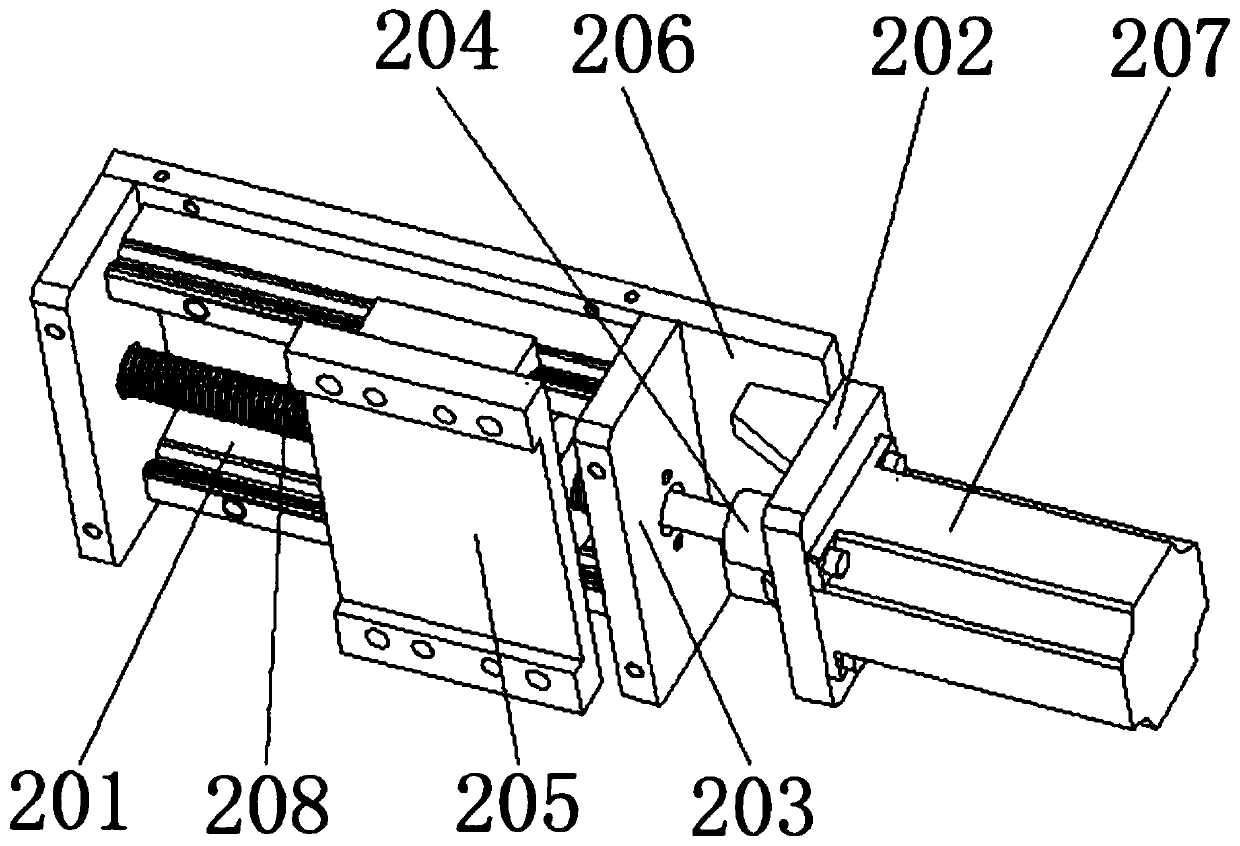

[0049] Such as figure 1 As shown, it includes a Z-axis motion system 1, an X-axis motion mechanism 2, a Y-axis motion mechanism 3, an XY-axis vibration device 4, a magnetorheological fluid circulation system 5, a polishing mechanism 6, a base platform 7 and a workpiece to be polished 8. The Z-axis motion system 1 is connected to the base platform 7 through screws, the X-axis motion mechanism 2 is connected to the Z-axis motion system 1 through screws, the Y-axis motion mechanism 3 is connected to the base platform 7 through screws, and the XY axis vibration device 4 is connected to Y through screws. The pad 309 of the axis movement mechanism 3 is connected, the polishing mechanism 6 is connected with the X axis movement mechanism 2 by screws, and the magnetorheological fluid circulation system 5 is connected with the polishing mechanism 6 by screws;

[0050] The workpiece 8 to be polished is fixed on the XY axis vibration device 4. The Y axis movement mechanism 3 drives the XY axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com