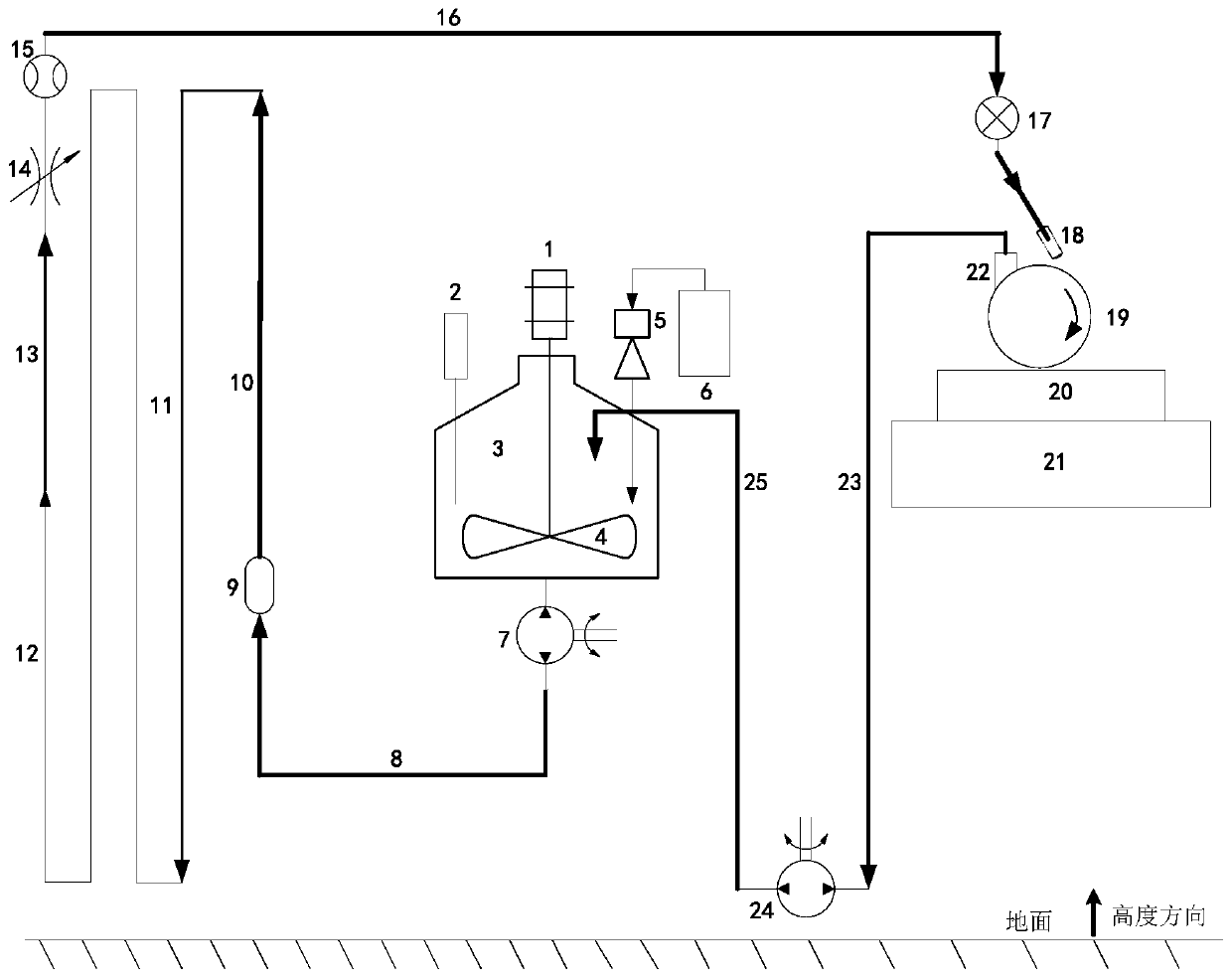

Magneto-rheological liquid circulation system of magneto-rheological polishing machine tool

A magnetorheological polishing and magnetorheological fluid technology, applied in grinding/polishing equipment, metal processing equipment, manufacturing tools, etc., can solve problems affecting the precision and efficiency of magnetorheological processing, flow fluctuations, changes, etc., to achieve Good flow stability control ability, removal function stability, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example 1

[0064] Specific example 1: When the flow rate of the magnetorheological fluid circulation system is less than 800ml / min:

[0065] The liquid storage tank 3 is a cylindrical structure with an inner diameter of 20mm, an outer diameter of 35mm, and a height of 40mm. The motor 1 is a servo motor with a speed of 5 to 50 rpm. The main body of the motor and the top cover of the liquid storage tank are connected together through tooling. It is connected with the stirring blade through a coupling, and the magnetorheological fluid is stirred in the liquid storage tank, and the stirring speed is adjustable from 5 to 50 rpm. At the center of the bottom of the liquid storage tank is a magneto-rheological fluid output port with a diameter of Ф8mm, which is connected to the inlet of the first peristaltic pump 7 .

[0066] The first peristaltic pump 7 is used for flow output. In order to suppress flow fluctuations, it is required to have high flow output stability. A high-precision peristalti...

specific example 2

[0071] Specific example 2: When the flow rate of the magnetorheological fluid circulation system is greater than 800ml / min:

[0072] The liquid storage tank 3 is a cylindrical structure with an inner diameter of 25mm, an outer diameter of 40mm, and a height of 40mm. The motor 1 is a servo motor with a speed of 20-50 rpm. The main body of the motor and the top cover of the liquid storage tank are connected together by tooling. The blades are connected by a coupling, and the magnetorheological fluid is stirred in the liquid storage tank, and the stirring speed is adjustable from 2 to 50 rpm. At the center of the bottom of the liquid storage tank is a magneto-rheological fluid output port with a diameter of Ф12 mm, which is connected to the inlet of the first peristaltic pump 7 .

[0073] The first peristaltic pump 7 is used for flow output. In order to suppress flow fluctuations, it is required to have high flow output stability. At the same time, it is necessary to ensure flow ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com