Metal nanoparticles with peroxidase activity and preparation method thereof

A technology of metal nanoparticles and peroxidase, which is applied in metal processing equipment, nanotechnology, transportation and packaging, etc., to achieve the effect of short cycle, simple method and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of palladium nanoparticles with peroxidase activity, the specific steps are as follows:

[0032] (1) Add 100 μL of 40 mM sodium dihydrogen phosphate-disodium hydrogen phosphate with a pH of 5.0 and 20 μL of 100 mM sodium tetrachloropalladate aqueous solution into a 1.5 mL centrifuge tube;

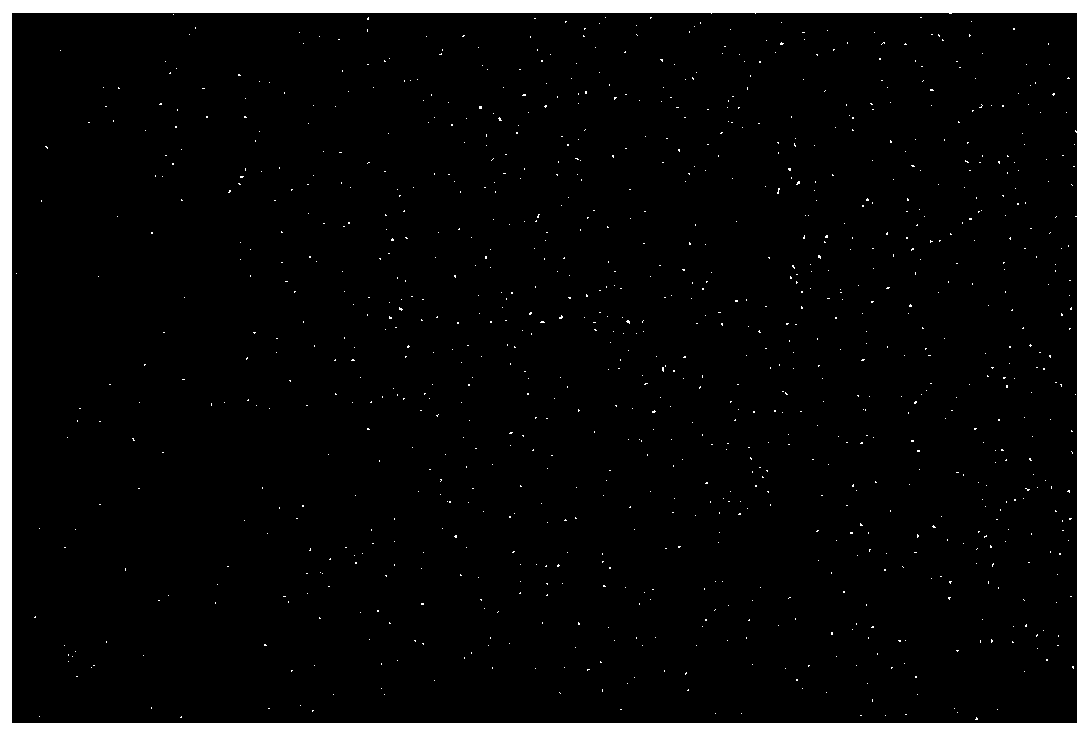

[0033] (2) Add 40 μL of 100 mM reduced coenzyme I disodium salt solution to the liquid obtained in step (1), add distilled water to make the final volume 400 μL, shake and mix, and stand at 25°C for 12 hours to obtain Enzyme-active palladium nanoparticle liquid (named NADH-Pd2.0 liquid), obtained by transmission electron microscope scanning, has an average particle diameter of 1.7nm (see figure 1 ).

[0034] Determination of Peroxidase Activity of Palladium Nanoparticles:

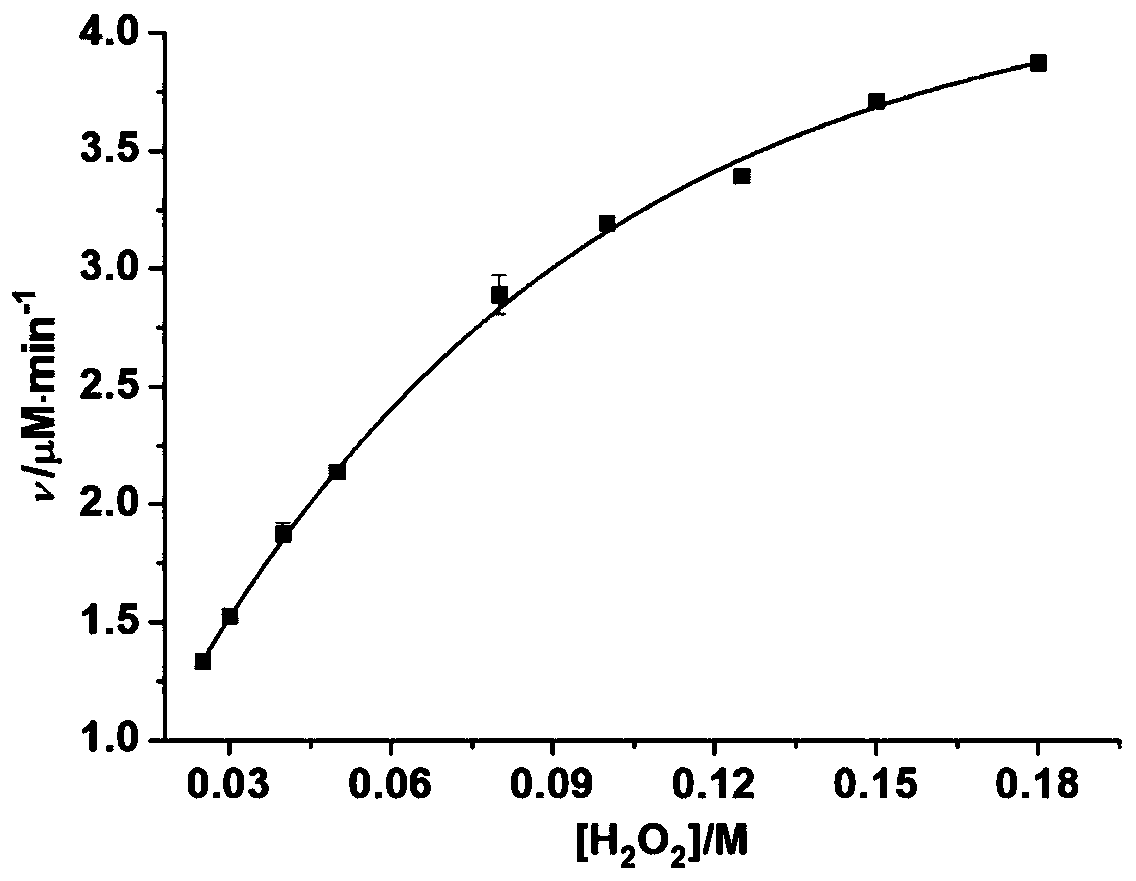

[0035] Experiment 1: Take 12 μL of the palladium nanoparticles liquid with peroxidase activity obtained in Example 1 in a 500 μL centrifuge tube and add 188 μL of distilled water for dilutio...

Embodiment 2

[0043] A preparation method of palladium nanoparticles with peroxidase activity, the specific steps are as follows:

[0044] (1) Add 200 μL of 20 mM potassium dihydrogen phosphate-dipotassium hydrogen phosphate buffer solution with a pH of 5.0 and 25 μL of 80 mM sodium tetrachloropalladate aqueous solution into a 1.5 mL centrifuge tube;

[0045] (2) Add 20 μL of 20 mM reduced coenzyme I disodium salt solution to the liquid obtained in step (1), add distilled water to make the final volume 400 μL, shake and mix, and stand at 20°C for 24 hours to obtain The enzyme-active palladium nanoparticle liquid (named NADH-Pd0.2 liquid) has an average particle diameter of 1.1 nm obtained by scanning a transmission electron microscope.

[0046] Determination method is the same as embodiment 1, to the K of 3,3',5,5'-tetramethylbenzidine m The value is 0.019mM, the K of hydrogen peroxide m The value is 142.4 mM.

[0047] Replace the sodium tetrachloropalladate of this embodiment with potas...

Embodiment 3

[0051] A preparation method of palladium nanoparticles with peroxidase activity, the specific steps are as follows:

[0052] (1) Add 100 μL of 40 mM sodium dihydrogen phosphate-phosphate buffer solution with a pH of 5.0 and 100 μL of 20 mM sodium tetrachloropalladate solution into a 1.5 mL centrifuge tube;

[0053] (2) Add 100 μL of 10 mM reduced coenzyme I disodium salt solution to the liquid obtained in step (1), add distilled water to make the final volume 400 μL, oscillate and mix, and stand at 25°C for 24 hours to obtain The active palladium nanoparticle liquid (named as NADH-Pd0.5 liquid) has an average particle diameter of 1.3 nm obtained by scanning a transmission electron microscope.

[0054] Determination method is the same as embodiment 1, to the K of 3,3',5,5'-tetramethylbenzidine m The value is 0.031mM, the K of hydrogen peroxide m The value is 100.3 mM.

[0055] Replace the sodium tetrachloropalladate of this embodiment with potassium tetrachloroplatinate, rep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Km value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com