Method for efficiently recovering positive electrode material of mixed lithium ion battery

A technology for ion batteries and positive electrode materials, which is applied in the field of efficient recovery of positive electrode materials for mixed lithium ion batteries, can solve the problems of comprehensive treatment and recycling of unfavorable waste batteries, separate utilization, and low purity, etc., and achieves suitability for industrial applications, loss reduction, and high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

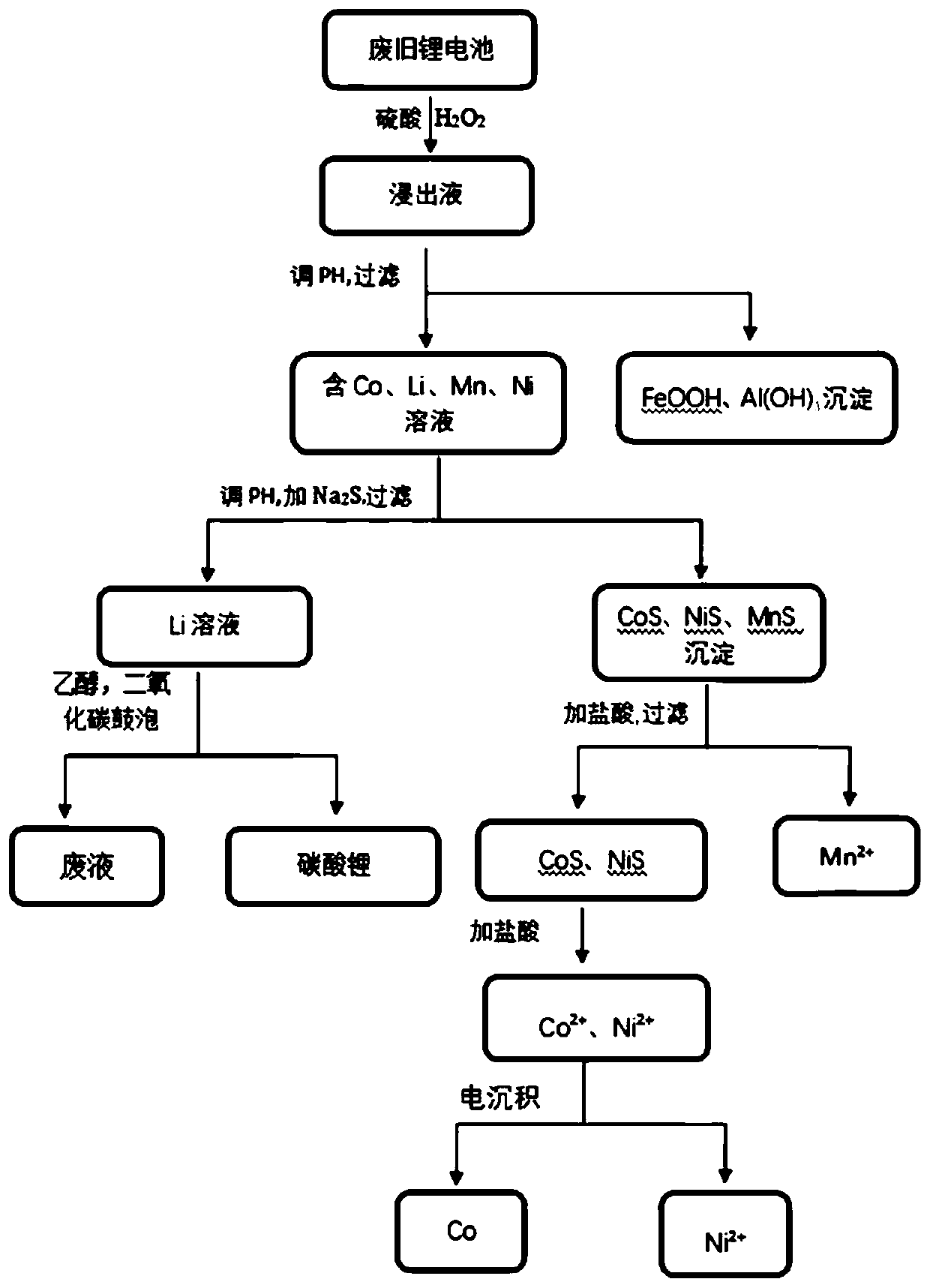

[0047] The method for efficiently recycling the positive electrode material of the mixed lithium-ion battery specifically comprises the following steps:

[0048] (1) Disassemble waste lithium-ion batteries containing different positive electrode materials lithium manganese oxide, lithium cobalt oxide, lithium iron phosphate, and nickel-cobalt lithium manganese oxide, take 25g of positive electrode powder, and use the filtered waste lead-acid battery electrolyte and H 2 o 2 for leaching, H 2 o 2 The addition amount of the battery is 20% of the electrolyte of the waste lead-acid battery, and the solid-liquid ratio is 25g / L. The leaching temperature is 90°C and the time is 90 minutes. The leaching process also includes stirring at a stirring speed of 200 rpm to obtain the leaching solution of the mixed lithium-ion battery cathode material;

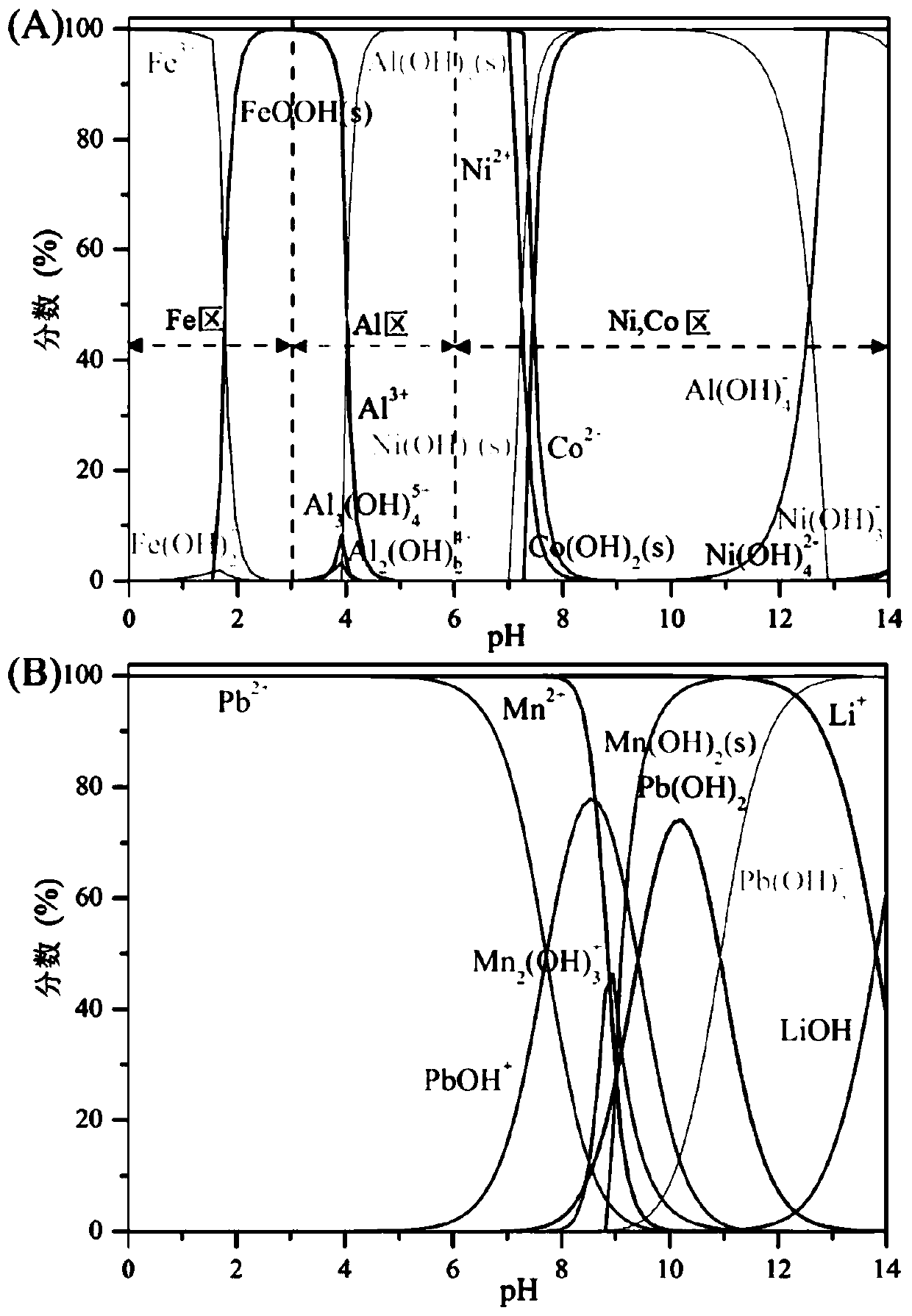

[0049] (2) with NH 4 OH adjusts the pH value of the leaching solution to 5, so that Fe 3+ and Al 3+ Precipitate, filter after keeping...

Embodiment 2

[0061] The method for efficiently recycling the positive electrode material of the mixed lithium-ion battery specifically comprises the following steps:

[0062] (1) Lithium-ion batteries containing different cathode materials lithium manganese oxide, lithium cobalt oxide, lithium iron phosphate, and nickel-cobalt lithium manganese oxide were disassembled respectively, and 25 g of positive electrode powder was taken, and mixed with 3mol / LH 2 SO 4 and H 2 o 2 Carry out leaching, the solid-to-liquid ratio is 20g / L, the leaching temperature is 95°C, and the time is 120min. The leaching process also includes stirring, and the stirring speed is 300rpm to obtain the leach solution of the mixed lithium-ion battery cathode material.

[0063] (2) Adjust the pH value of the leaching solution to 6.5 with NaOH, so that Fe 3+ and Al 3+ precipitation, followed by filtration to separate the precipitate from solution;

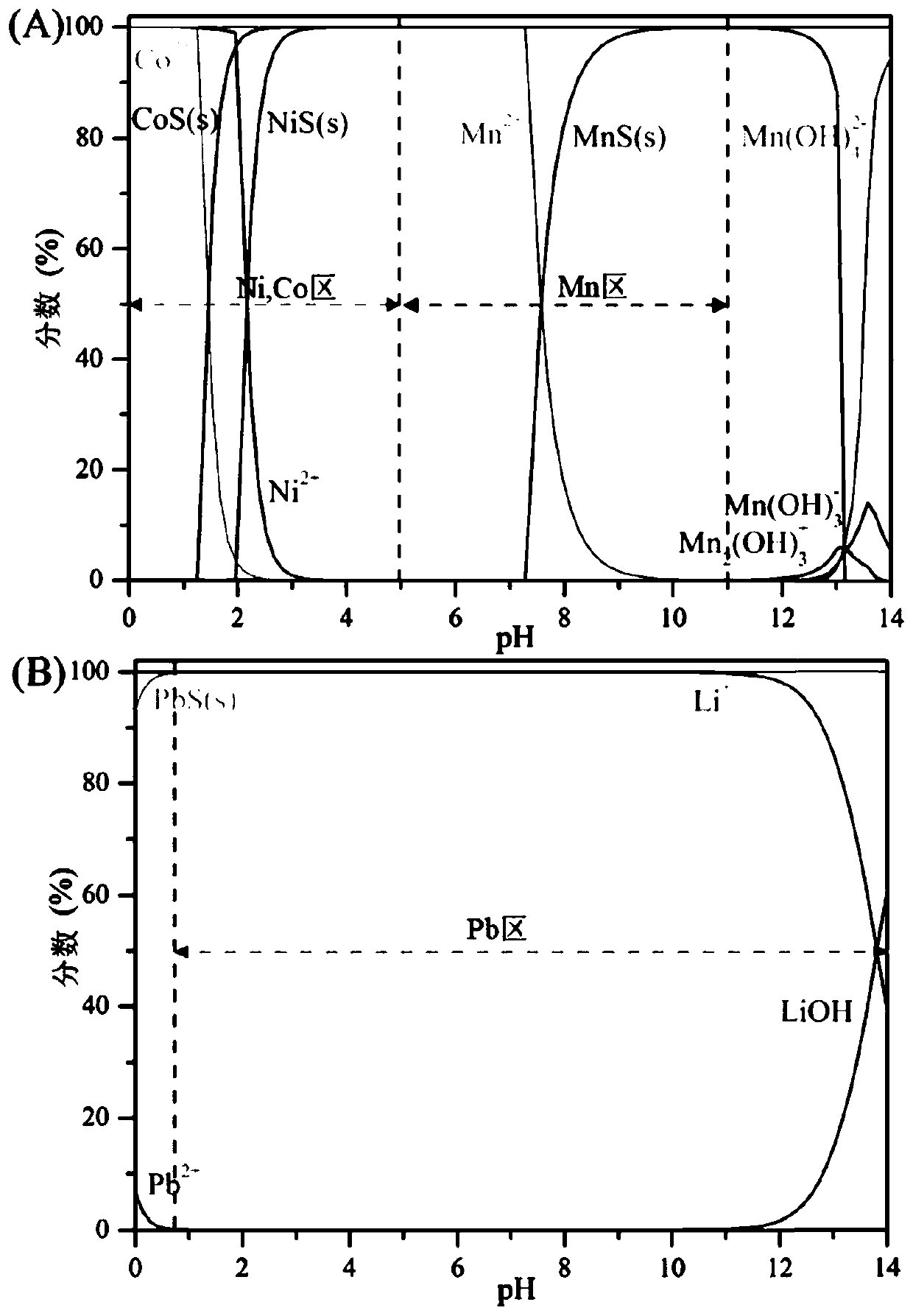

[0064] (3) Adjust the pH value of the remaining solution to 10, add ...

Embodiment 3

[0072] The method for efficiently recycling the positive electrode material of the mixed lithium-ion battery specifically comprises the following steps:

[0073] (1) Disassemble waste lithium-ion batteries containing different cathode materials lithium manganese oxide, lithium cobalt oxide, lithium iron phosphate, and nickel-cobalt lithium manganese oxide, take 50 g of positive electrode powder, and use the filtered waste lead-acid battery electrolyte and H 2 o 2 for leaching, H 2 o 2 The addition amount is 22% of the waste lead-acid battery electrolyte. The solid-to-liquid ratio is 40g / L, the leaching temperature is 95°C, and the time is 120min. The leaching process also includes stirring at a stirring speed of 300rpm to obtain the leaching solution of the mixed lithium-ion battery cathode material;

[0074] (2) with NH 4 OH adjusts the pH value of the leaching solution to 5.4, so that Fe 3+ and Al 3+ Precipitate, filter after keeping for 1.5h, separate the precipitate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com