A Method for Separating Heat Source Regions of Electrical Equipment Based on Improved Seed Filling Algorithm

A technology for electrical equipment and separation methods, applied in computing, image analysis, computer parts, etc., can solve the problems of large amount of calculation, excessive manual optimization, omission and deviation, etc., to improve efficiency and reliability, and simplify repeatability Operational, adaptable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be noted that the following embodiments are intended to facilitate the understanding of the present invention, but do not limit it in any way.

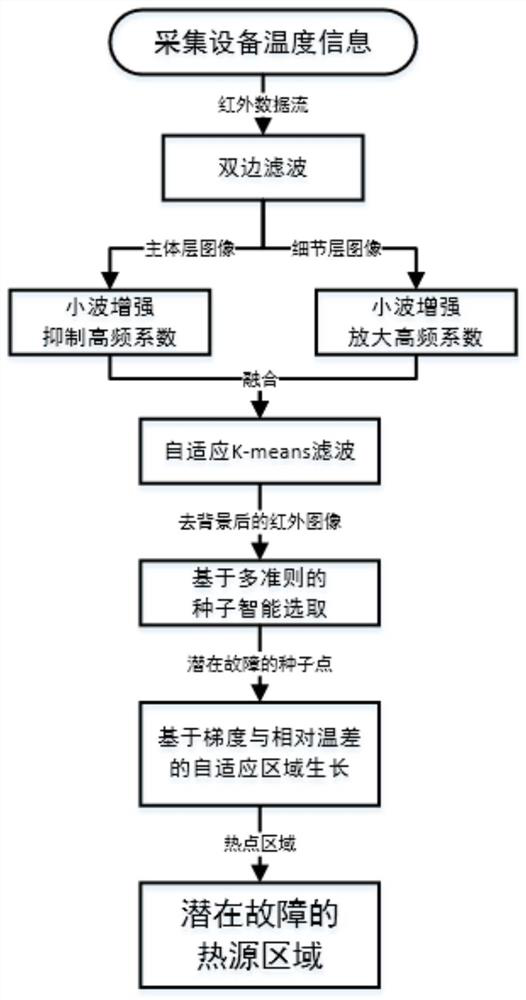

[0049] like figure 1 As shown, a method for separating heat source areas of electrical equipment based on the improved seed filling algorithm is used to process and analyze the actually collected infrared thermal image information of electrical equipment. The specific steps are described as follows:

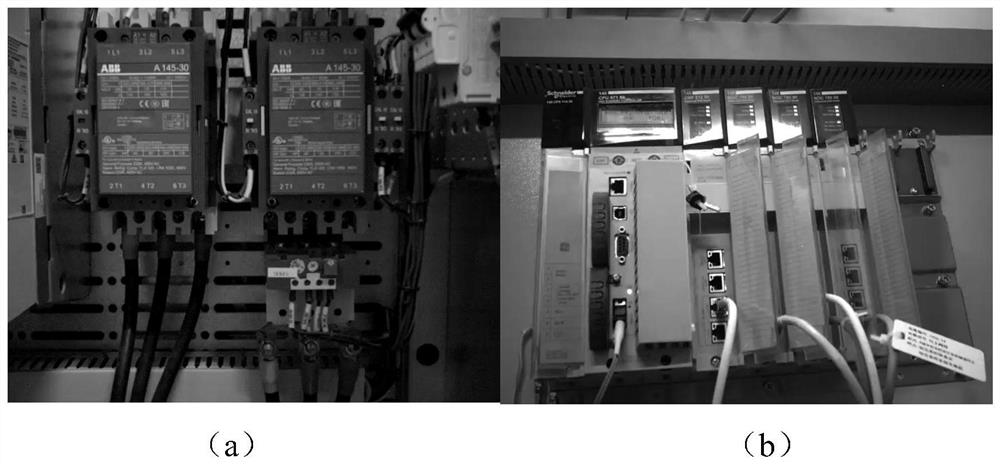

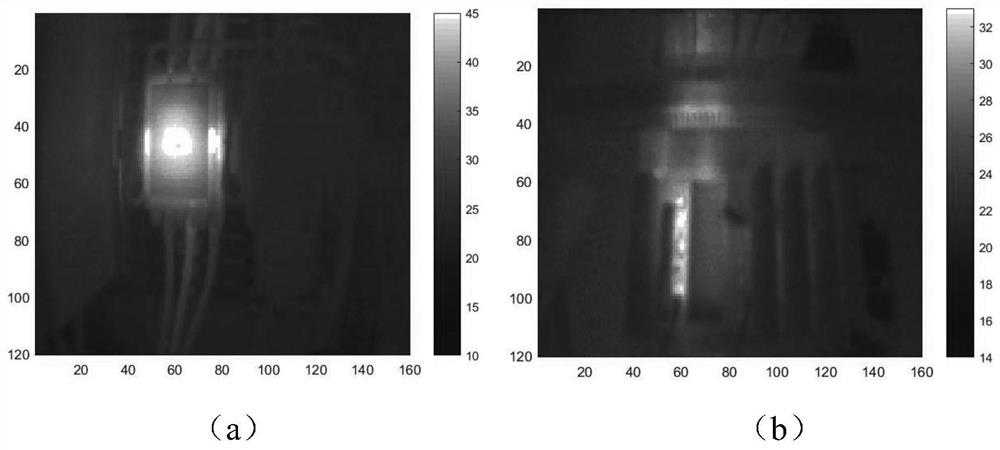

[0050] S01, the infrared thermal imaging sensor monitors the temperature of electrical equipment such as AC contactors and switches, and obtains infrared thermal image data information. The detection target in this embodiment is as figure 2 As shown, it should be pointed out that the present embodiment involves Figure 2 to Figure 10 Among them, (a) corresponds to ABB contactor A145-30, and (b) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com