Combustion device for water quality detection

A combustion device and water quality detection technology, applied in the direction of using combustion for chemical analysis, etc., can solve problems such as sticking to the combustion tube, measurement error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

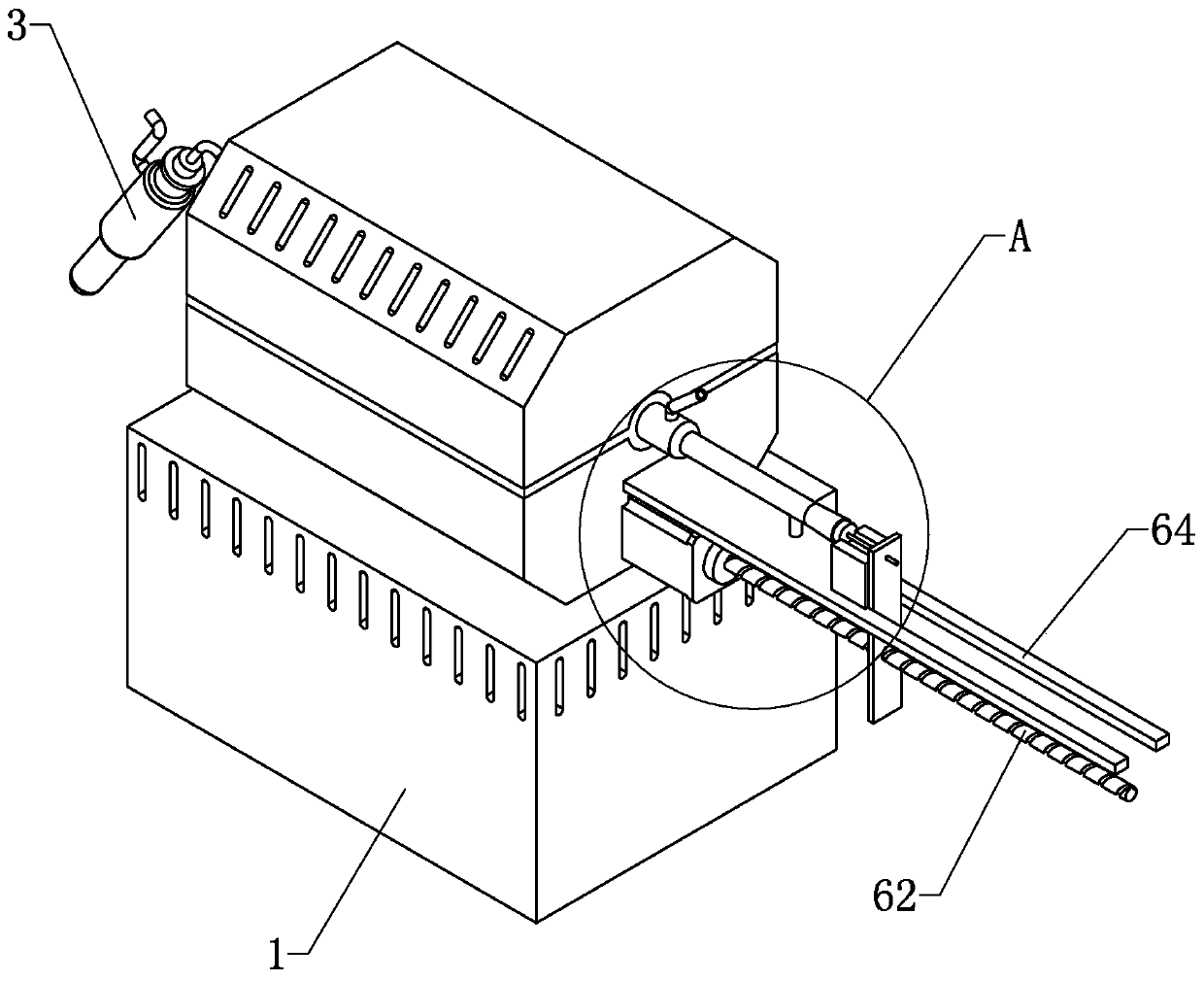

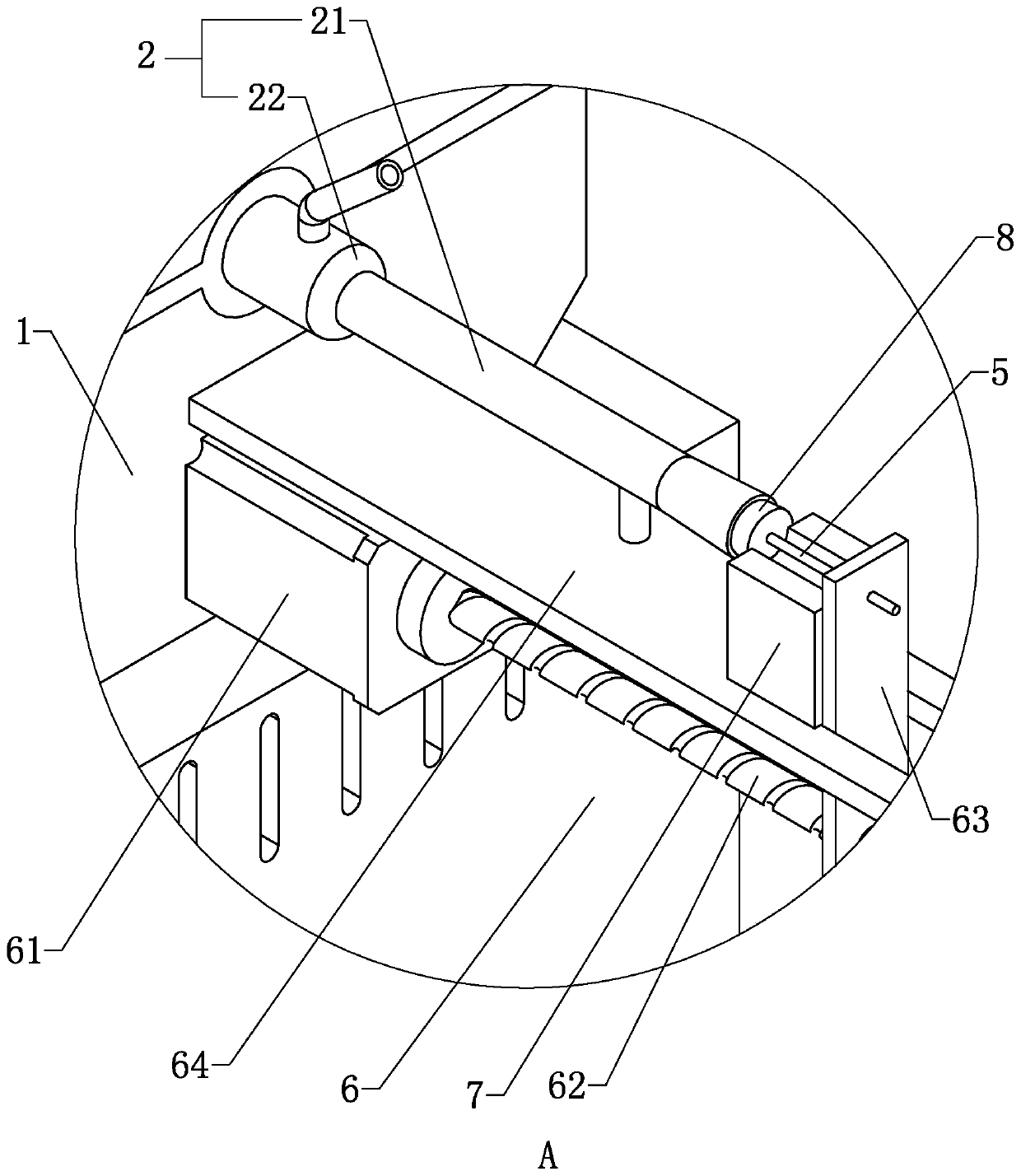

[0040] Embodiment one: a kind of combustion device for water quality detection, such as figure 1 , figure 2 As shown, it includes a combustion furnace 1, a combustion tube 2 passing through the combustion furnace 1, an absorption tube 3 connected to the outlet end of the combustion tube 2, and a sample plate 4 for holding samples ( Figure 4 ), wherein the combustion tube 2 includes a combustion outer tube 22 that runs through the combustion furnace 1, and a combustion inner tube 21 that supports the sample plate 4. When working, both the combustion inner tube 21 and the combustion outer tube 22 need to be fed with oxygen for the sample plate. 4 on the activated carbon combustion.

[0041] The feeding ends of the combustion inner pipe 21 and the combustion outer pipe 22 are not connected, and an air inlet is respectively provided at the feeding ends. Wherein the air intake of combustion inner pipe 21 is arranged vertically, and is positioned at the bottom of combustion inne...

Embodiment 2

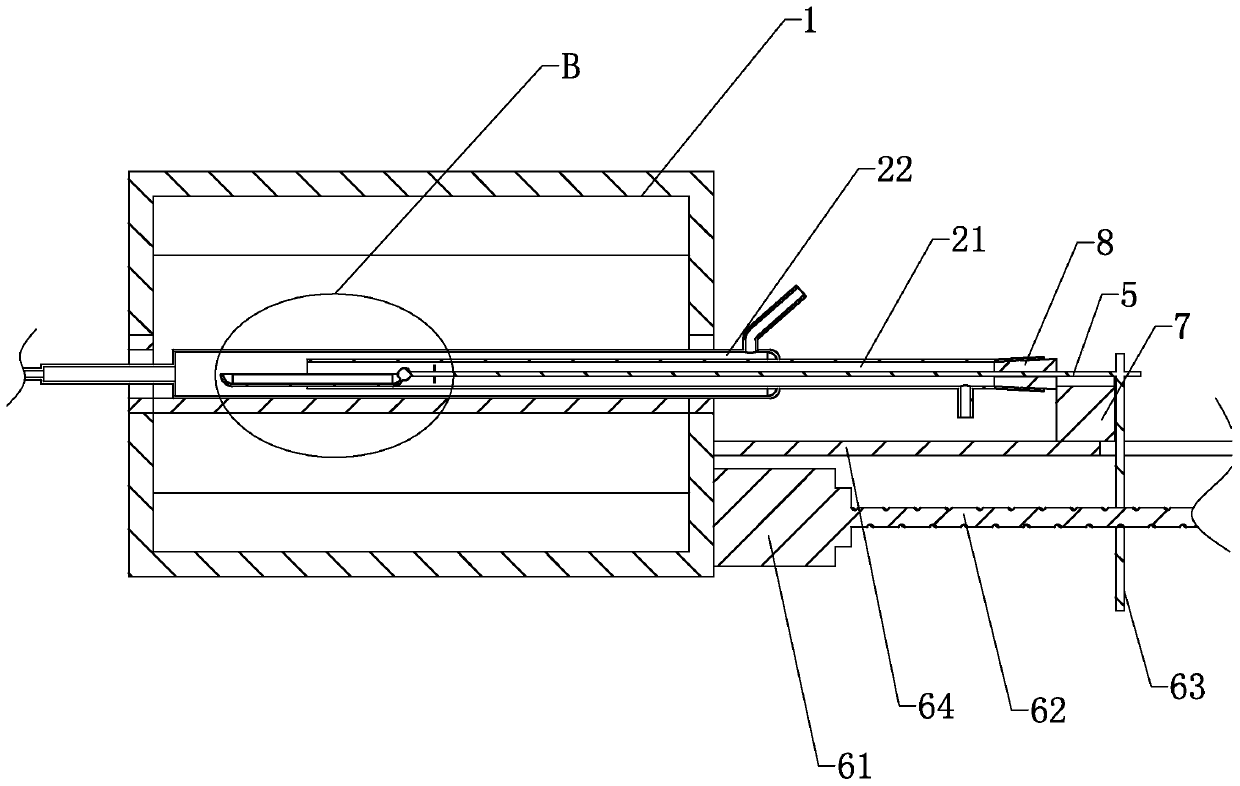

[0053] Embodiment two: a kind of combustion device for water quality detection, such as Figure 5 As shown, when the push rod 5 moves in and out, the sealing relationship of the combustion tube 2 must be ensured, so the sealing plug 8 is used to seal the opening of the combustion tube 2 at the feed end.

[0054] The push rod 5 passes through the sealing plug 8 and is slidably connected with the sealing plug 8 , and friction stripes are provided at the abutment between the sealing plug 8 and the push rod 5 to increase the friction force. Therefore, when it is necessary to use the sealing plug 8 to close the combustion tube 2, the friction stripes drive the sealing plug 8 to move toward the combustion tube 2 until the sealing plug 8 is tightly pressed against the combustion tube 2, and one end of the sealing plug 8 is located in the combustion tube 2, and the other One end is located outside the combustion tube 2.

[0055] One end of the sealing plug 8 located in the combustion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com