E-type inductor automatic assembly machine and assembly method thereof

An automatic assembly machine, automatic assembly technology, applied in the direction of inductance/transformer/magnet manufacturing, circuits, electrical components, etc., can solve problems such as low production efficiency, improve production efficiency, ensure position accuracy, and solve problems of low production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

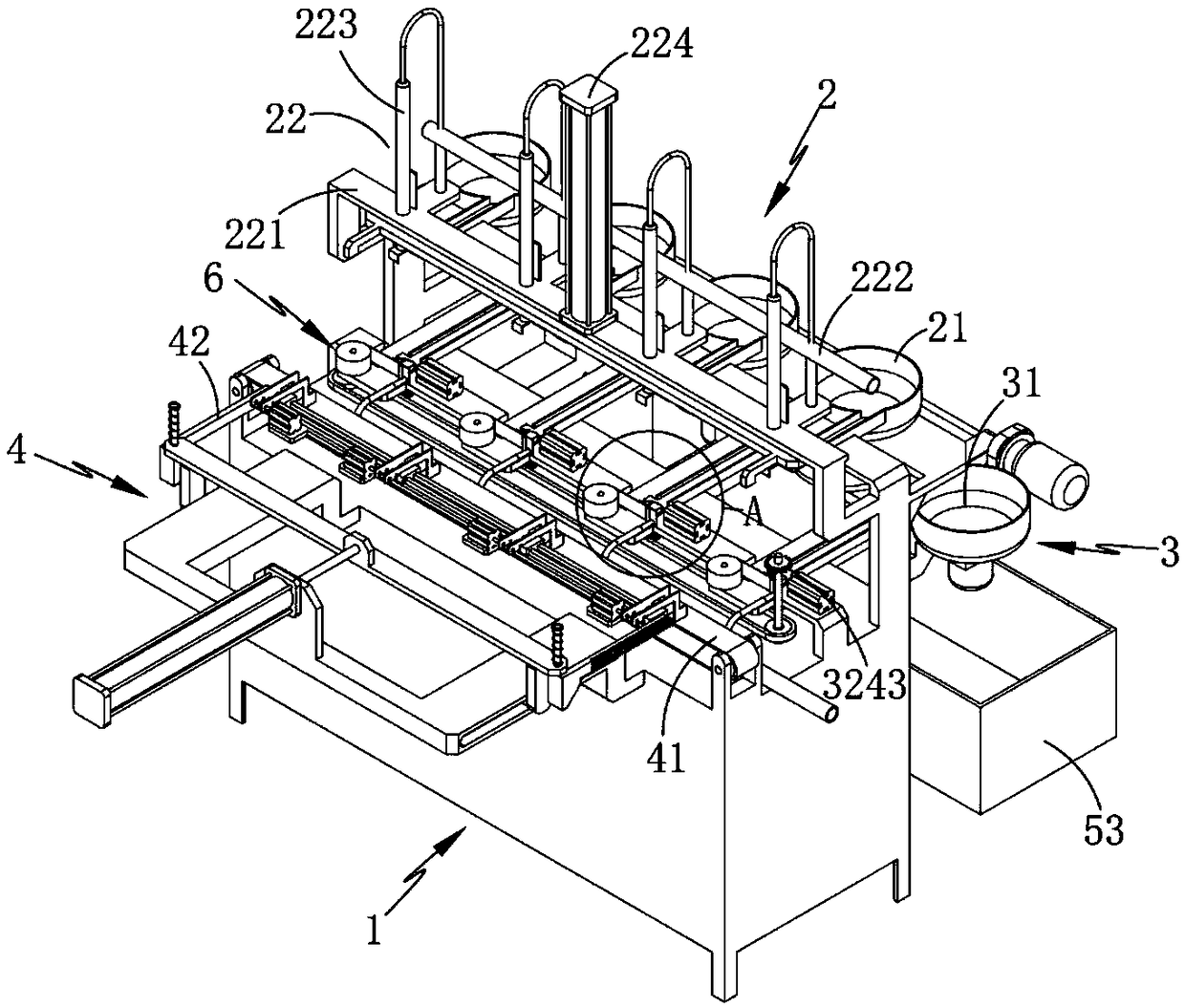

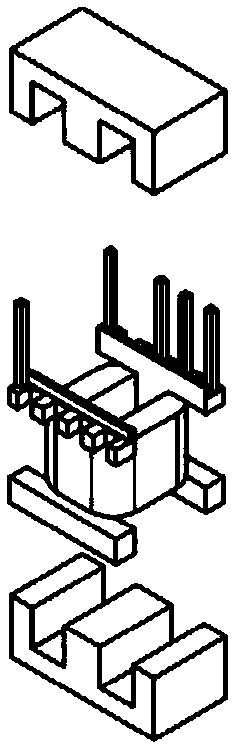

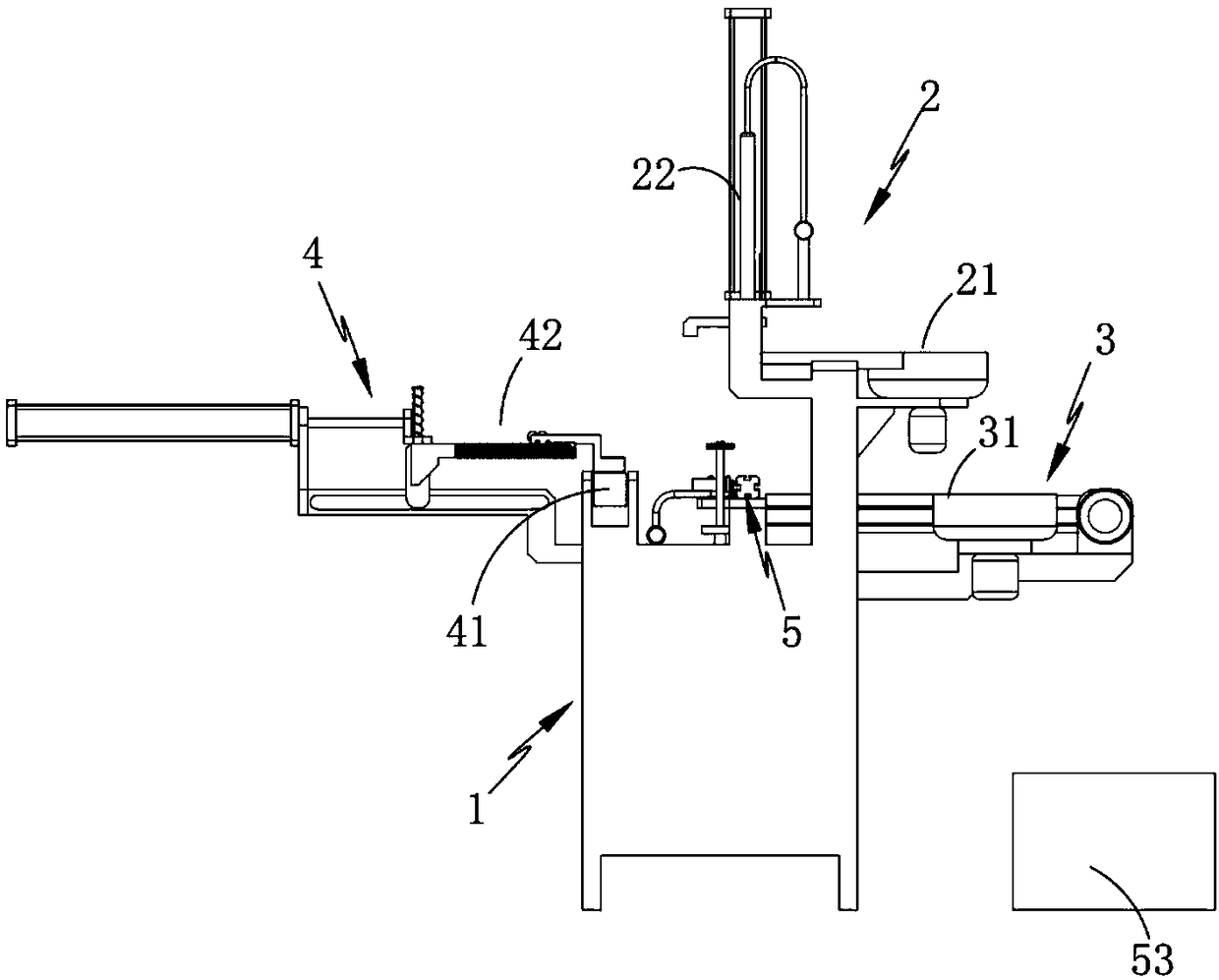

[0047] like figure 1 , 2 , 3, 4 and 5, an E-shaped inductance automatic assembly machine, including a frame 1, is characterized in that it also includes:

[0048] The magnetic core A transfer mechanism 2, the magnetic core A transfer mechanism 2 includes a sorting component I21 and a feeding component 22 located above the sorting component I21; through the sorting component I21, a number of magnetic cores A in it are sorted in sequence, and then The feeding assembly 22 transfers the sorted magnetic cores A downward one by one i...

Embodiment 2

[0058] Among them such as figure 1 and 10 As shown, the parts that are the same as or corresponding to those in the first embodiment adopt the reference numerals corresponding to the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below; the differences between the second embodiment and the first embodiment The position is: the feeding assembly 42 includes a moving frame A421 that moves horizontally along the horizontal chute 11 provided on the frame 1, a vertical moving frame 422 arranged on the moving frame A421, and arranged side by side on the vertical moving frame A421. A plurality of feeding parts 423 on the straight moving frame 422, a driving member 424 driving the reciprocating motion of the moving frame A421, and a transmission member 425 arranged on the vertical moving frame 422 and intermittently connected to the transmission part 324, In this embodiment, the transmission member 425 is provided as a rack a...

Embodiment 3

[0062] Among them such as figure 1 , 5As shown in and 9, the parts identical or corresponding to those in the second embodiment adopt the reference numerals corresponding to the second embodiment. For the sake of simplicity, only the differences between the second embodiment and the second embodiment are described below; The difference is that it also includes a film winding assembly 6 arranged outside the positioning assembly 32, which includes a film roll 61, a support column 62 positioned on one side of the film roll 61 to support the film, and a support column 62 arranged between the support column 62 and the film roll. The cutting knife 63 that cuts the film between the positioning platforms 322 and the air pipe 64 that is arranged on one side of the support column 62 to carry out intermittent blowing and air suction to the film, the cutting knife 63 and the pushing assembly 51 is connected by transmission and the direction of movement of the two is opposite. In this emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com