Prefabricated concrete shear wall panel connecting method employing prestressed steel strand for vertical connection

A technology of prestressed steel strands and prefabricated concrete, which is applied to walls, building components, and earthquake resistance. It can solve the problems of difficult positioning of steel bars and sleeves, difficulty in ensuring grouting quality, and affecting connection effects, so as to increase construction difficulty and increase Ease of construction workload and connection quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

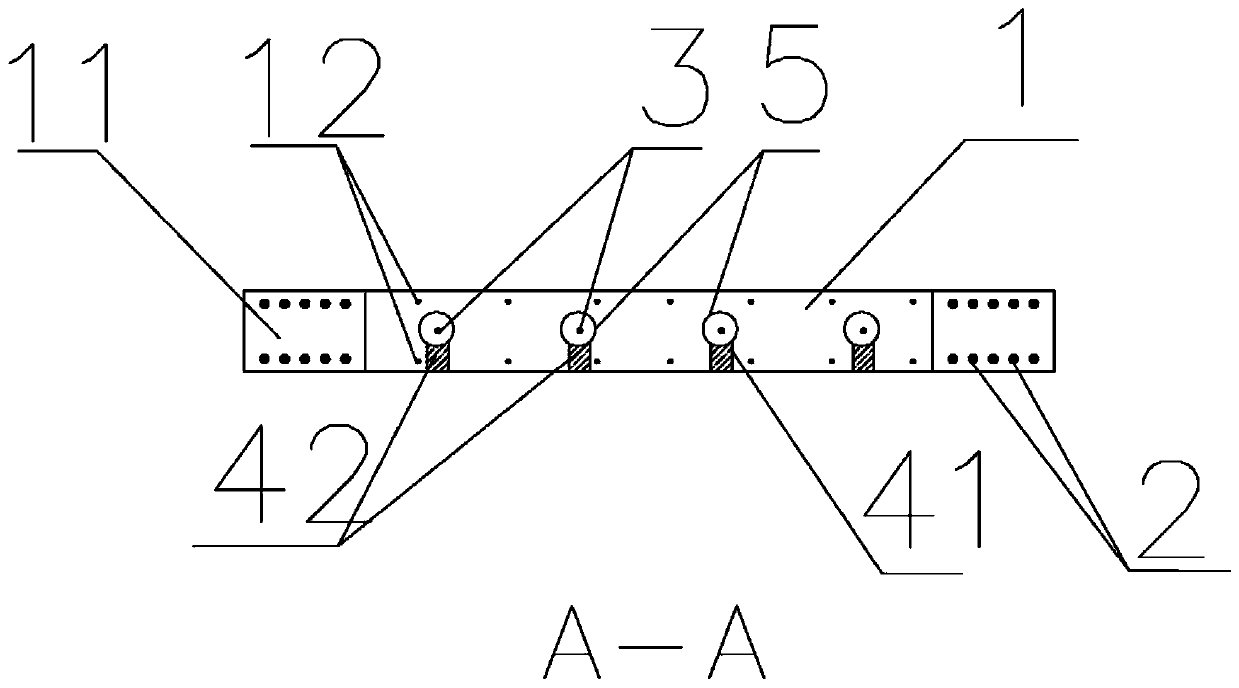

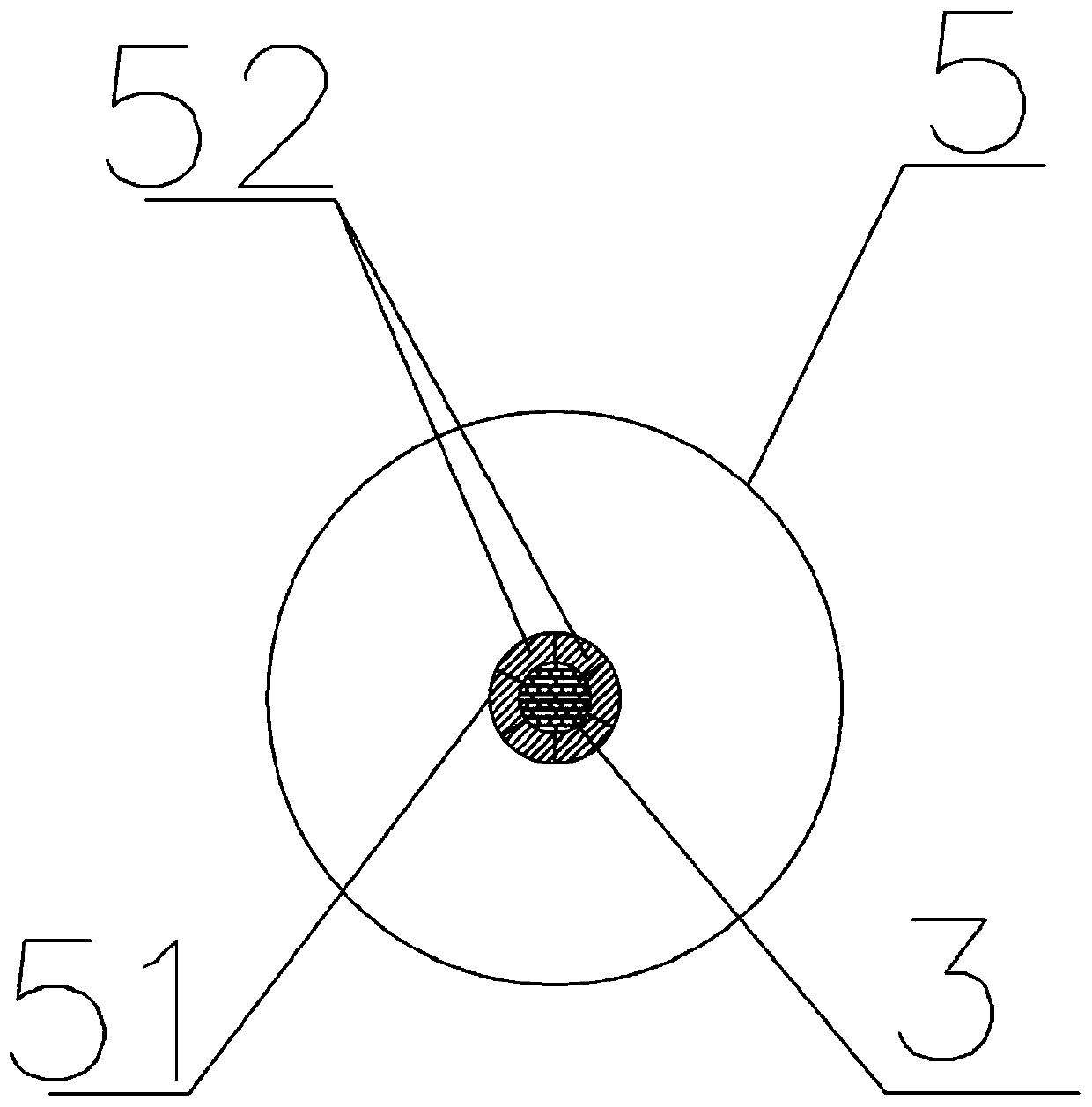

[0031] Please refer to the attached figure 1 to attach image 3 As shown, the present invention is a method for connecting prefabricated concrete shear wall panels vertically connected by prestressed steel strands. 12 and several parts such as steel strand 3.

[0032] Wherein, the edge vertical steel bars 2 are arranged at edge positions on both sides of the wall body 1 . The wall body 1 leaves a rectangular gap 11 at the bottom of the corresponding position of the edge vertical reinforcement 2 . The lower part of the edge vertical steel bar 2 is exposed in the rectangular gap 11 . A rectangular notch 11 is left at the bottom of the edge of the wall 1, which facilitates the mechanical connection or lapping of the thicker steel bars at this position, and the connection quality of the steel bars is convenient for inspection and acceptance. At the same time, the concrete at the notch 11 can be connected to the wall. The cast-in-place connection parts are poured at the same ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com