EVA adhesive film for packaging solar photovoltaic module, and preparation method thereof

A solar photovoltaic and adhesive film technology, applied in adhesives, electrical components, semiconductor devices, etc., can solve the problems of reduced photoelectric conversion efficiency of solar photovoltaic modules, affecting the service life of solar photovoltaic modules, and decreased light transmittance of adhesive films. Electrical insulation performance, good transparency, and the effect of increasing the degree of crosslinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

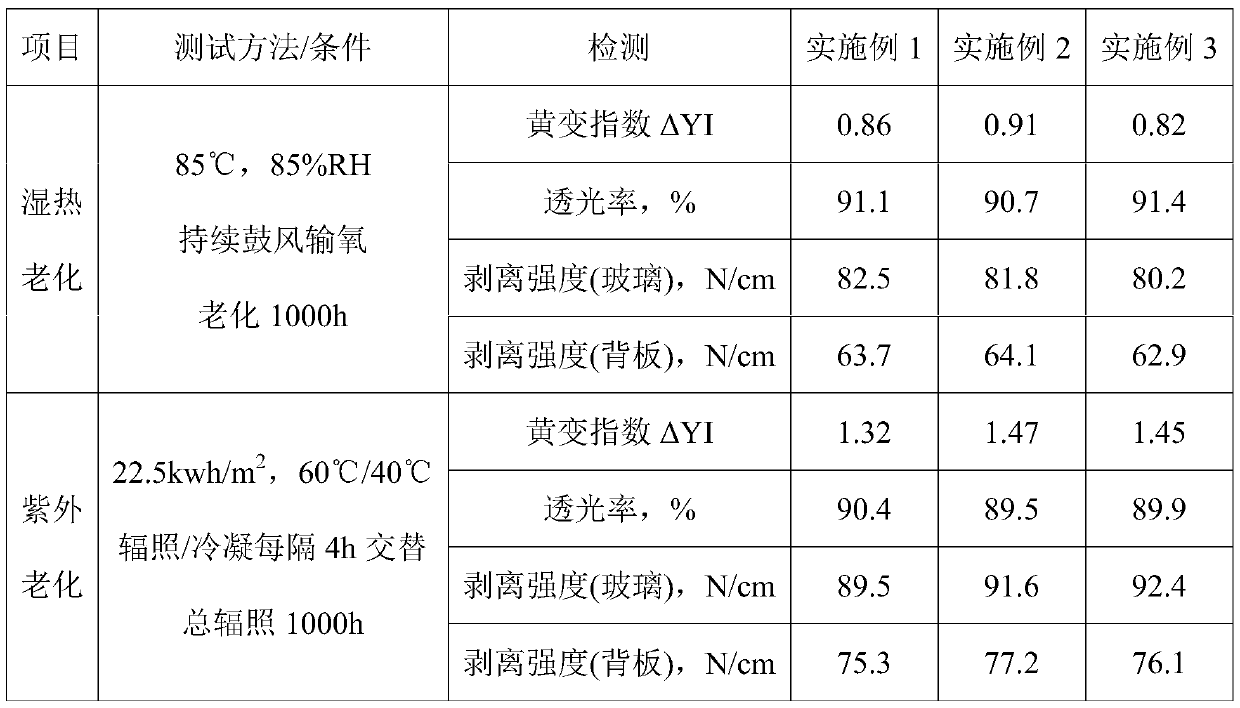

Embodiment 1

[0031] The EVA adhesive film for encapsulating solar photovoltaic modules of this embodiment is prepared from the following raw materials in parts by weight: 100 parts of EVA resin, 0.9 parts of tert-butyl peroxy-2-ethylhexyl carbonate, 2,5-dimethyl 0.6 parts of 2,5-bis(tert-butylperoxy)hexane, 0.45 parts of 3-methacryloxypropyl triethoxysilane, 0.15 parts of vinyl triethoxysilane, methyl 4.0 parts of vinyl silicone resin, 0.10 parts of ultraviolet absorber, and 0.10 parts of antioxidant.

[0032] The preparation method of the solar photovoltaic module encapsulation EVA adhesive film of the present embodiment comprises the following steps:

[0033]1) Put the formulated amount of EVA resin granules in a high-speed mixer, take the formulated amount of methyl vinyl silicone resin powder and add it to the EVA resin granules, stir at a speed of 1000rpm for 5 minutes to make the system evenly mixed; then add the formulated amount Peroxy-2-ethylhexyl tert-butyl carbonate, 2,5-dimeth...

Embodiment 2

[0037] The EVA adhesive film for encapsulating solar photovoltaic modules of this embodiment is prepared from the following raw materials in parts by weight: 100 parts of EVA resin, 0.8 parts of tert-butyl peroxy-2-ethylhexyl carbonate, 2,5-dimethyl 0.7 parts of 2,5-bis(tert-butylperoxy)hexane, 0.40 parts of 3-methacryloxypropyl triethoxysilane, 0.20 parts of vinyl triethoxysilane, methyl 3.5 parts of vinyl silicone resin, 0.15 parts of ultraviolet absorber, and 0.05 parts of antioxidant.

[0038] The preparation method of the solar photovoltaic module encapsulation EVA adhesive film of the present embodiment comprises the following steps:

[0039] 1) Put the formulated amount of EVA resin granules in a high-speed mixer, take the formulated amount of methyl vinyl silicone resin powder and add it to the EVA resin granules, and stir at a speed of 1200rpm for 3 minutes to make the system evenly mixed; then add the formulated amount Peroxy-2-ethylhexyl tert-butyl carbonate, 2,5-d...

Embodiment 3

[0043] The EVA adhesive film for encapsulating solar photovoltaic modules of this embodiment is prepared from the following raw materials in parts by weight: 100 parts of EVA resin, 1.0 parts of tert-butyl peroxy-2-ethylhexyl carbonate, 2,5-dimethyl 0.5 parts of 2,5-bis(tert-butylperoxy)hexane, 0.50 parts of 3-methacryloxypropyl triethoxysilane, 0.10 parts of vinyl triethoxysilane, methyl 4.5 parts of vinyl silicone resin, 0.12 parts of ultraviolet absorber, and 0.08 parts of antioxidant.

[0044] The preparation method of the solar photovoltaic module encapsulation EVA adhesive film of the present embodiment comprises the following steps:

[0045] 1) Put the formulated amount of EVA resin granules in a high-speed mixer, take the formulated amount of methyl vinyl silicone resin powder and add it to the EVA resin granules, stir at a speed of 1000rpm for 5 minutes to make the system evenly mixed; then add the formulated amount Peroxy-2-ethylhexyl tert-butyl carbonate, 2,5-dimet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com