Nylon elastomer nano composite material and preparation method thereof

A technology of nanocomposite materials and nylon elastomers, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of polyamide failing to enter the interlayer in time, product performance impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] In this embodiment, the mass ratio of nanomaterials to nylon elastomer is 15:100, the nylon elastomer is PA6 series, the mass ratio of PA6 to polyether block is 95:5, and the liquid medium used is water. The auxiliary agent is lecithin, and the nano-material used is nano-praseodymium oxide, and the nano-composite material is prepared according to the following method:

[0088] (1) Stir the liquid medium, and at the same time add nanomaterials at a speed of 8g / min for continuous stirring and disperse evenly, the weight ratio of liquid medium to nanomaterials is 16:1;

[0089] (2) Add additives in batches or at a time to the continuously stirring solution of step (1) at a speed of 0.1 g / min to obtain a paste, the consistency of which is 31 mm, and the additives and nanomaterials The weight ratio is 20:1;

[0090] (3) the paste obtained in step (2) is mixed with nylon elastomer to obtain a premix;

[0091] (4) feeding the premixed material in step (3) into a screw extrud...

Embodiment 2

[0095] In this embodiment, the mass ratio of nanomaterials to nylon elastomer is 10:100, the nylon elastomer is PA66 series, the mass ratio of PA66 to polyether block is 95:5, and the liquid medium used is ethylene glycol Alcohol dimethyl ether and water, the mass ratio of ethylene glycol dimethyl ether and water is 6:4, the auxiliary agent adopted is polyacrylic acid and heavy polyamine epichlorohydrin resin, the weight ratio is 1:1, adopts The nanomaterial is nano-zinc oxide, and the nanocomposite material is prepared according to the following method:

[0096] (1) Stir the liquid, and at the same time add nanomaterials at a speed of 10g / min for continuous stirring to disperse evenly, and the weight ratio of the liquid medium to the nanomaterials is 100:1;

[0097] (2) add auxiliary agent in the continuous stirring solution of step (1) with the speed of 0.5g / min, obtain paste, the consistency of described paste is 24mm, and the weight ratio of described auxiliary agent and n...

Embodiment 3

[0103] In this embodiment, the mass ratio of nanomaterials to nylon elastomer is 0.1:100, the nylon elastomer is PA12 series, the mass ratio of PA12 to polyether block is 95:5, the liquid medium used is water, and The auxiliary agent is Capres resin, and the nano-materials used are nano-silicon carbide and nano-erbium oxide, and the mass ratio is 9:1. The nano-composite material is prepared according to the following method:

[0104] (1) Stir the liquid medium, and at the same time add nanomaterials at a speed of 0.01g / min for continuous stirring to disperse evenly, and the weight ratio of liquid medium to nanomaterials is 50:1;

[0105] (2) Add additives to the continuous stirring solution of step (1) at a speed of 10g / min to obtain a paste, the consistency of the paste is 69mm, and the weight ratio of the additives to nanomaterials is 0.1 :1;

[0106] (3) the paste obtained in step (2) is mixed with nylon elastomer to obtain a premix;

[0107] (4) feeding the premixed mate...

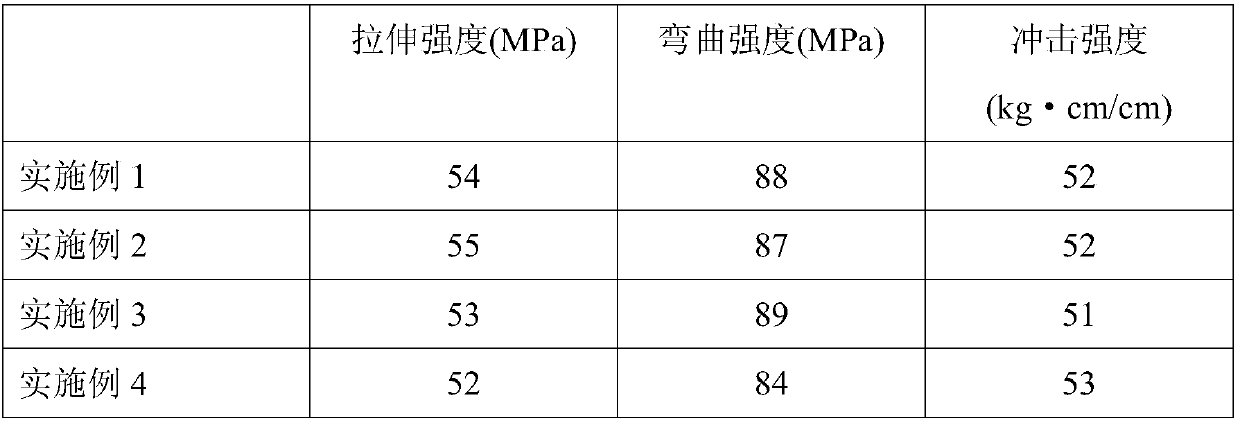

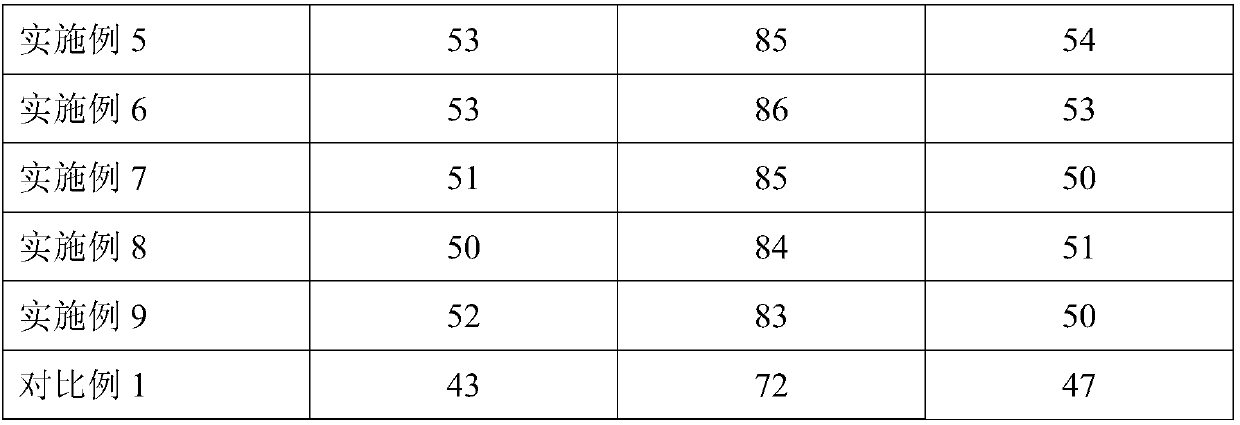

PUM

| Property | Measurement | Unit |

|---|---|---|

| flow consistency | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com