Glass fiber three-dimensional reinforced lightweight cement slab

A technology of glass fiber and three-dimensional reinforcement, which is applied in the field of glass fiber three-dimensionally reinforced lightweight cement slats. It can solve the problems of high cost and complicated process, and achieve quality reduction, good strength, and increased The effect of structural strength and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

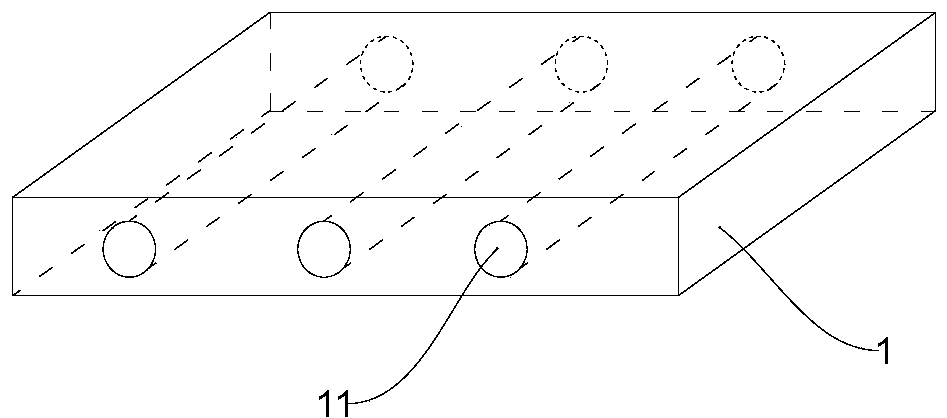

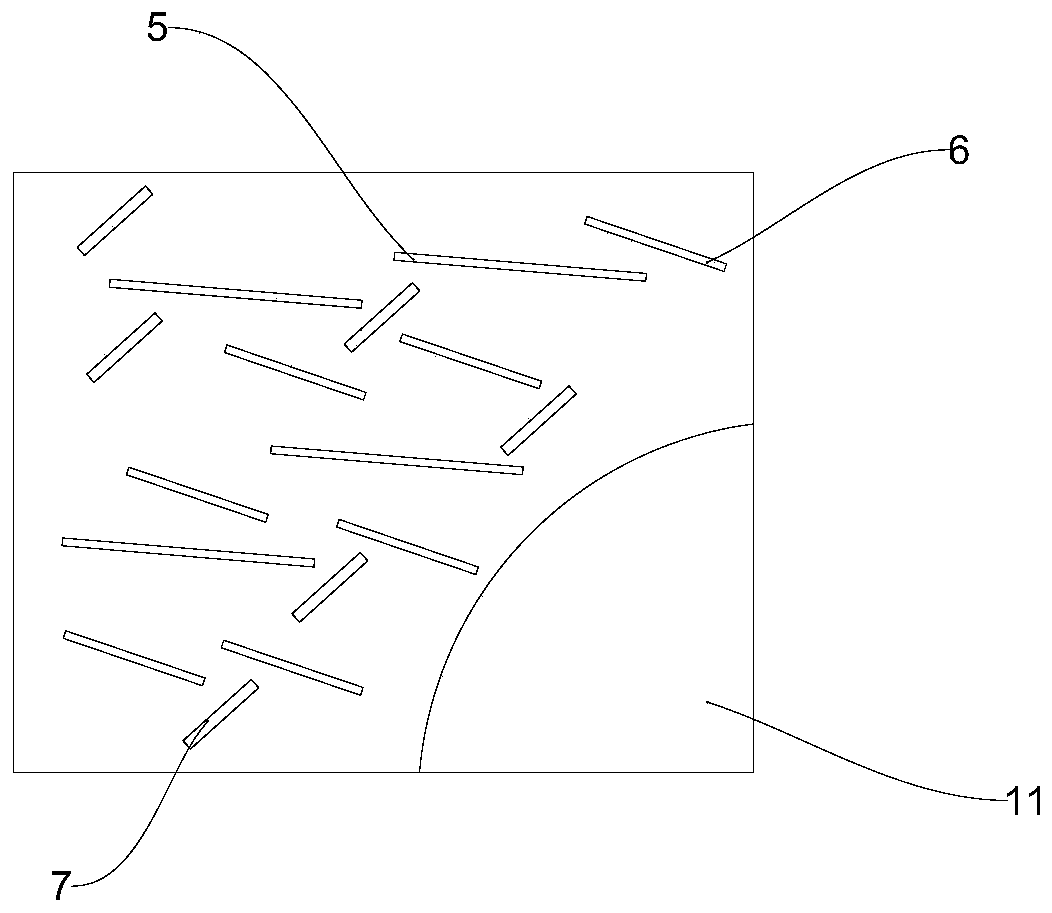

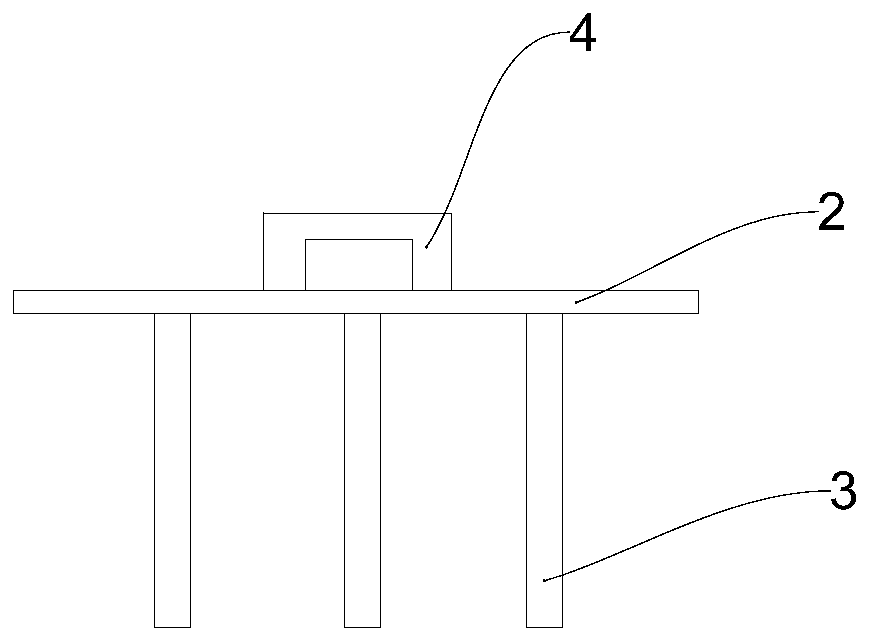

[0043] A glass fiber three-dimensionally reinforced lightweight cement strip, the cement strip is formed by a composite slurry casting mold, with glass fiber mesh cloth on both sides; the composite slurry includes the following raw materials in parts by weight: 12 Part of coal ash, 0.3 part of mixed glass fiber, 1 part of fine sand, 1 part of vermiculite, 1 part of ceramsite, 30 parts of water, 0.3 part of regulator, 0.1 part of micro-expansion agent, 37.5 parts of cement; wherein, the mixed glass The fibers are obtained by mixing glass fibers with lengths of 0.5cm, 1.6cm, and 2.6cm in a mass ratio of 3:1:1; the regulator includes the following raw materials in parts by weight: 10 parts of triethylene glycol dimethyl Acrylates, 2 parts Lauryl Methacrylate, 5 parts Trimethylolpropane Triacrylate, 5 parts Propylene Glycol Methyl Ether Acetate.

[0044] The processing technology of the glass fiber three-dimensionally reinforced lightweight cement batten comprises the following st...

Embodiment 2

[0051] A glass fiber three-dimensionally reinforced lightweight cement strip, the cement strip is formed by a composite slurry casting mold, with glass fiber mesh cloth on both sides; the composite slurry includes the following raw materials in parts by weight: 0.1 Parts of graphene, 12 parts of coal ash, 0.3 part of mixed glass fiber, 1 part of fine sand, 1 part of vermiculite, 1 part of ceramsite, 30 parts of water, 0.3 part of regulator, 0.1 part of micro-expansion agent, 37.5 parts of cement; , the mixed glass fiber is obtained by mixing glass fibers with lengths of 0.5cm, 1.6cm, and 2.6cm according to a mass ratio of 3:1:1; the regulator includes raw materials in the following parts by weight: 10 parts of triethyl Glycol Dimethacrylate, 2 parts Lauryl Methacrylate, 5 parts Trimethylolpropane Triacrylate, 5 parts Propylene Glycol Methyl Ether Acetate.

[0052] Described processing technology is consistent with embodiment 1.

Embodiment 3

[0054] A glass fiber three-dimensionally reinforced lightweight cement strip, the cement strip is formed by a composite slurry casting mold, with glass fiber mesh cloth on both sides; the composite slurry includes the following raw materials in parts by weight: 46 1 part of coal ash, 12 parts of perlite, 1 part of mixed glass fiber, 0.5 part of graphene, 8 parts of fine sand, 6 parts of vermiculite, 5 parts of ceramsite, 35 parts of water, 1.5 parts of regulator, 0.4 part of micro expansion agent, 75 parts of cement; wherein, the mixed glass fibers are obtained by mixing glass fibers with a length of 1.5cm, 2.5cm, and 3.5cm according to a mass ratio of 6:5:1; the conditioner includes the following raw materials in parts by weight : 15 parts of triethylene glycol dimethacrylate, 5 parts of lauryl methacrylate, 8 parts of trimethylolpropane triacrylate, 10 parts of propylene glycol methyl ether acetate.

[0055] The processing technology of the glass fiber three-dimensionally re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com