Preparation method of copper-rich modified defect titanium dioxide and cuprous sulfide heterojunction hydrogen production catalyst

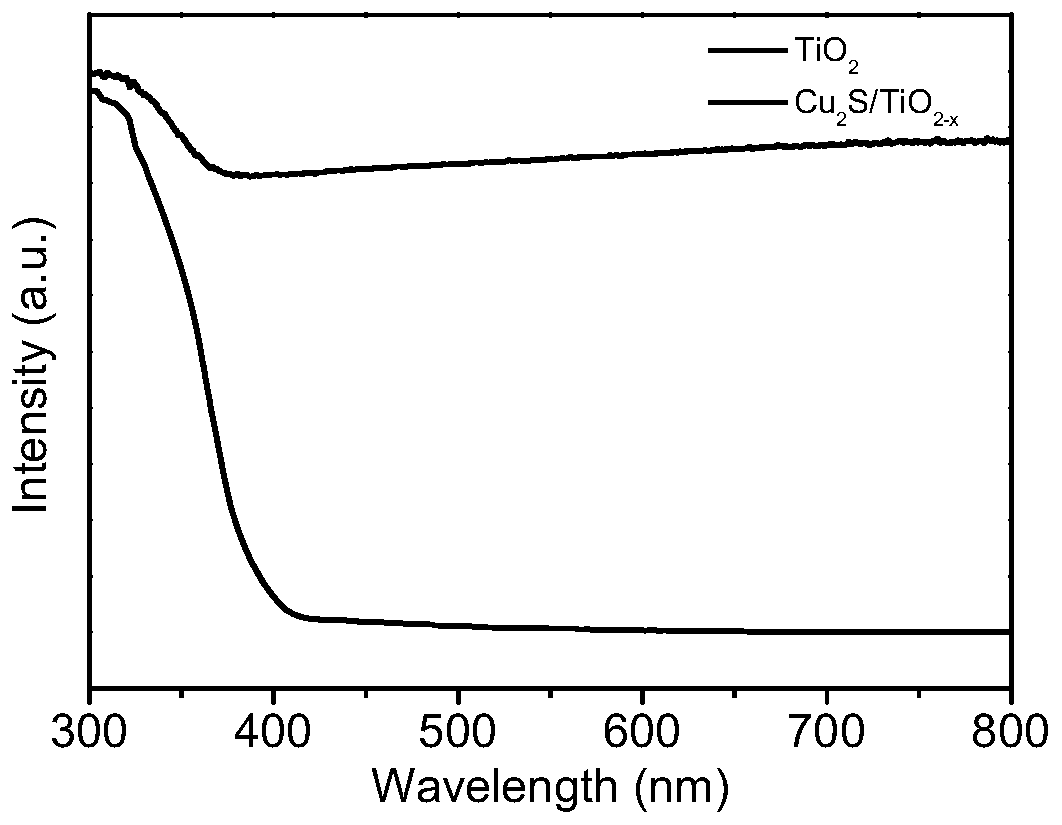

A technology of titanium dioxide and cuprous sulfide, which is used in the preparation and application of nanomaterials, can solve the problems of accelerating the diffusion rate of hot carriers, reducing the high recombination rate of photogenerated electrons and holes, etc., and achieves low cost, simple method, and sample high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0021] A Cu-doped modified defect TiO 2 、Cu 2 The preparation method of S heterojunction photocatalyst: this preparation method comprises the following steps:

[0022] (1), Cu doped modified TiO 2 For the preparation of nanostructures, add 1.6 g of F127 [poly(ethylene glycol)-block-poly(propylene glycol)-block-poly(ethylene glycol), molecular weight: 13000] and 0.2 g of copper acetate to 30 mL of ethanol solvent, Stir at 60°C for 1 hour at a speed of 500rpm to fully dissolve it; then add 2.3mL of acetic acid (35%), 0.7mL of hydrochloric acid (36%), and 3.5mL of TBT (tetrabutyl titanate) to the solution Continue to stir for 30 minutes, the speed is still 500rpm; move the mixed solution into an electric blast drying oven, and dry it at 60°C for 24 hours to obtain Cu-doped TiO 2 sol-gel; the resulting Cu-doped TiO 2 The sol-gel sample was transferred to a muffle furnace for high-temperature calcination, and the temperature was raised to 450°C at a rate of 5°C / min and kept for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com