Descaling method and device for heating coil of reaction vessel

A technology of heating coils and reactors, which is applied in the direction of cleaning heat transfer devices, lighting and heating equipment, chemical instruments and methods, etc., can solve the problems of reduced heat transfer effect on the heating surface, reduction of heat exchange parameters, secondary pollution, etc. Achieve the effects of easy popularization and application, simple device structure, convenient use and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

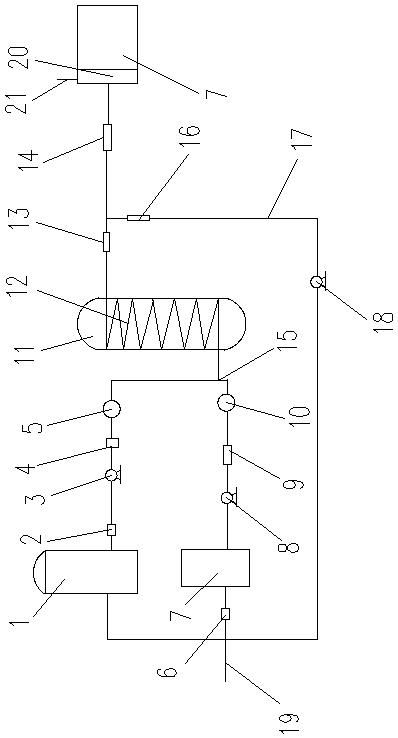

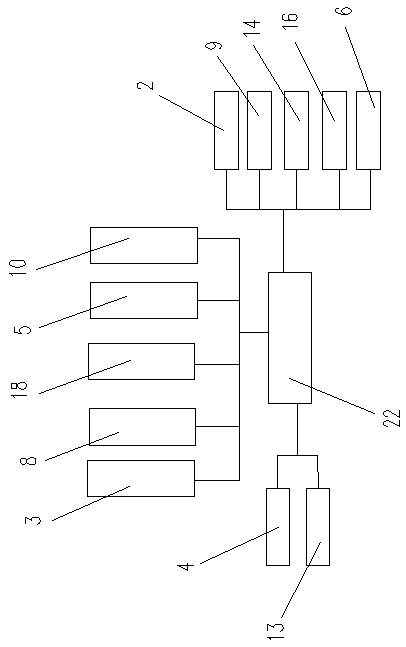

[0032] 1. Input of process parameters: before use, put the No. 1 material liquid pump 2, the circulating water pump 8, the No. 2 material liquid pump 18, the No. 1 solenoid valve 2, the No. 2 solenoid valve 14, the No. 3 solenoid valve 16, and the No. 4 solenoid valve 9. The process parameters of No. 5 solenoid valve 6 , No. 1 flow meter 5 , No. 2 flow meter 10 and acid-base tester 13 are input into the console 22 .

[0033] 2. Mixing of the descaling agent: input the aqueous hydrochloric acid solution with a mass percentage concentration of 2-8% and the sodium hypochlorite aqueous solution with a mass percentage concentration of 0.5-1% into the descaling agent storage tank 1 for mixing.

[0034] 3. Delivery of descaling agent and circulating water: the console 22 issues instructions to simultaneously open No. 1 solenoid valve 2, No. 4 solenoid valve 9, No. 1 material liquid pump 3 and circulating water pump 8 to transport descaling agent and circulating water respectively Mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com