Secondary side synchronous rectification controller circuit capable of adaptively driving voltage regulation period by period

A driving voltage and synchronous rectification technology, which is applied in control/regulation systems, high-efficiency power electronic conversion, instruments, etc., can solve the problem of not being applicable to other types of primary-side controller architectures, poor user experience, and inability to apply to primary-side controllers And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further illustrate a secondary side synchronous rectification controller circuit with cycle-by-cycle self-adaptive driving voltage adjustment of the present invention, the technical means adopted to achieve the intended purpose of the invention and the effects achieved, the following will be combined with the accompanying drawings and preferred embodiments , a detailed description will be given of the specific implementation, structure, features and efficacy of the secondary edge synchronous rectification controller circuit for cycle-by-cycle adaptive drive voltage adjustment proposed by the present invention.

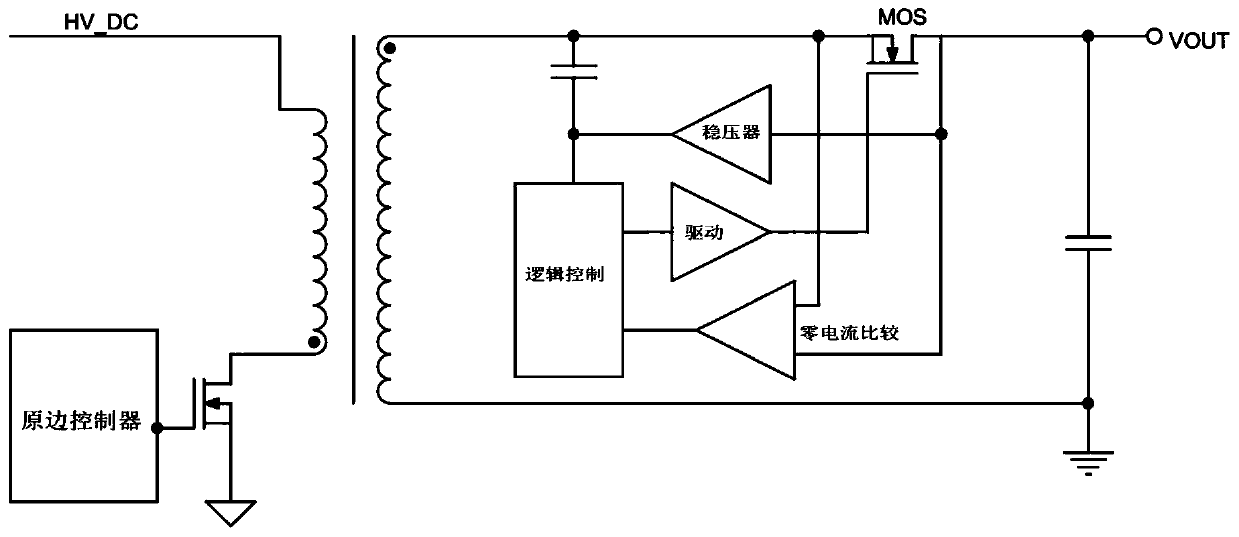

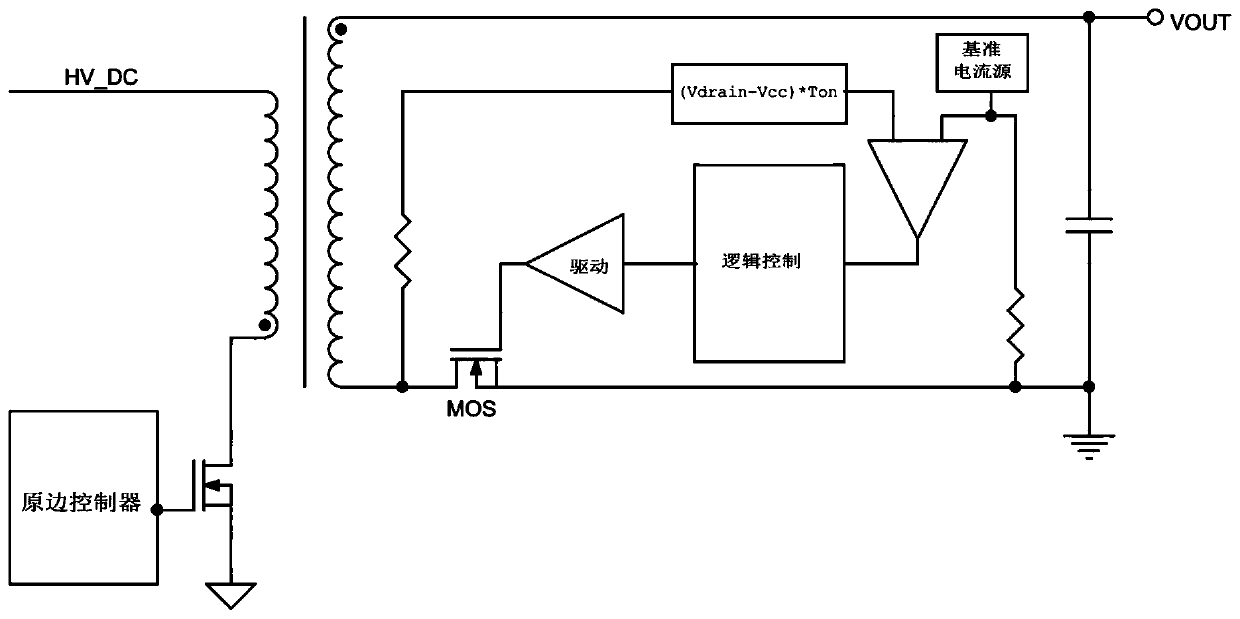

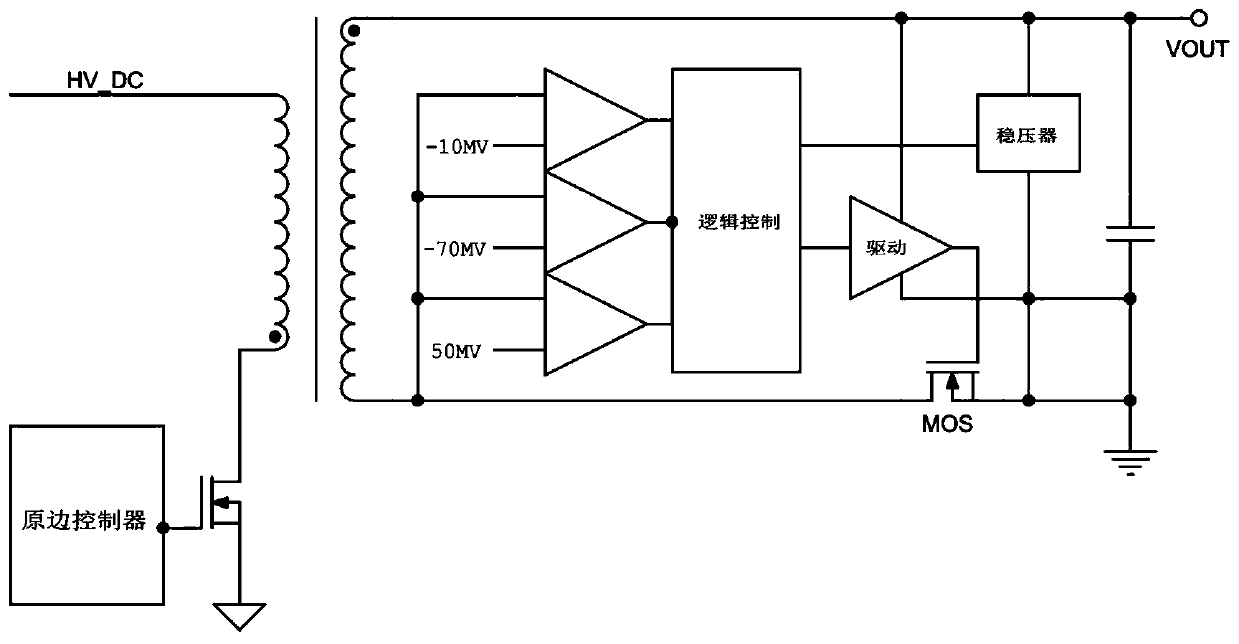

[0019] Please refer to Figure 1 to Figure 3 , which is a structural schematic diagram of an exemplary synchronous rectification controller circuit.

[0020] exist figure 1 Among them, in order to use the zero-current comparator to realize DCM and QR mode synchronous rectification, the zero-current comparator directly samples the voltage at both end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com