Ejector and fuel cell hydrogen inlet adjusting and hydrogen-returning device applying same

An ejector and mounting hole technology, which is applied in the field of a fuel cell hydrogen intake adjustment and hydrogen return device, can solve the problems of difficulty in processing and manufacturing the ejector, poor versatility, poor interchangeability, high design and development, and high test costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

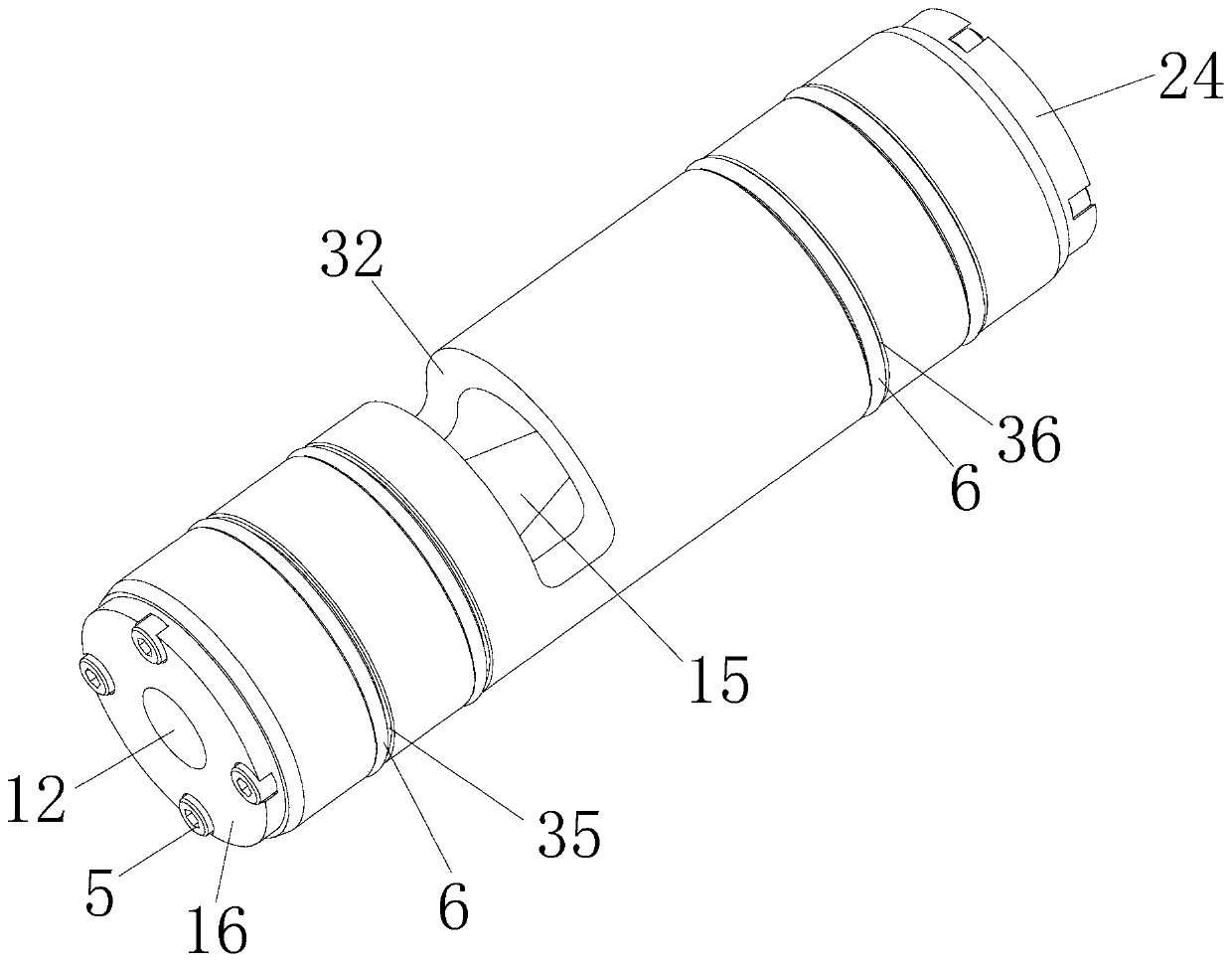

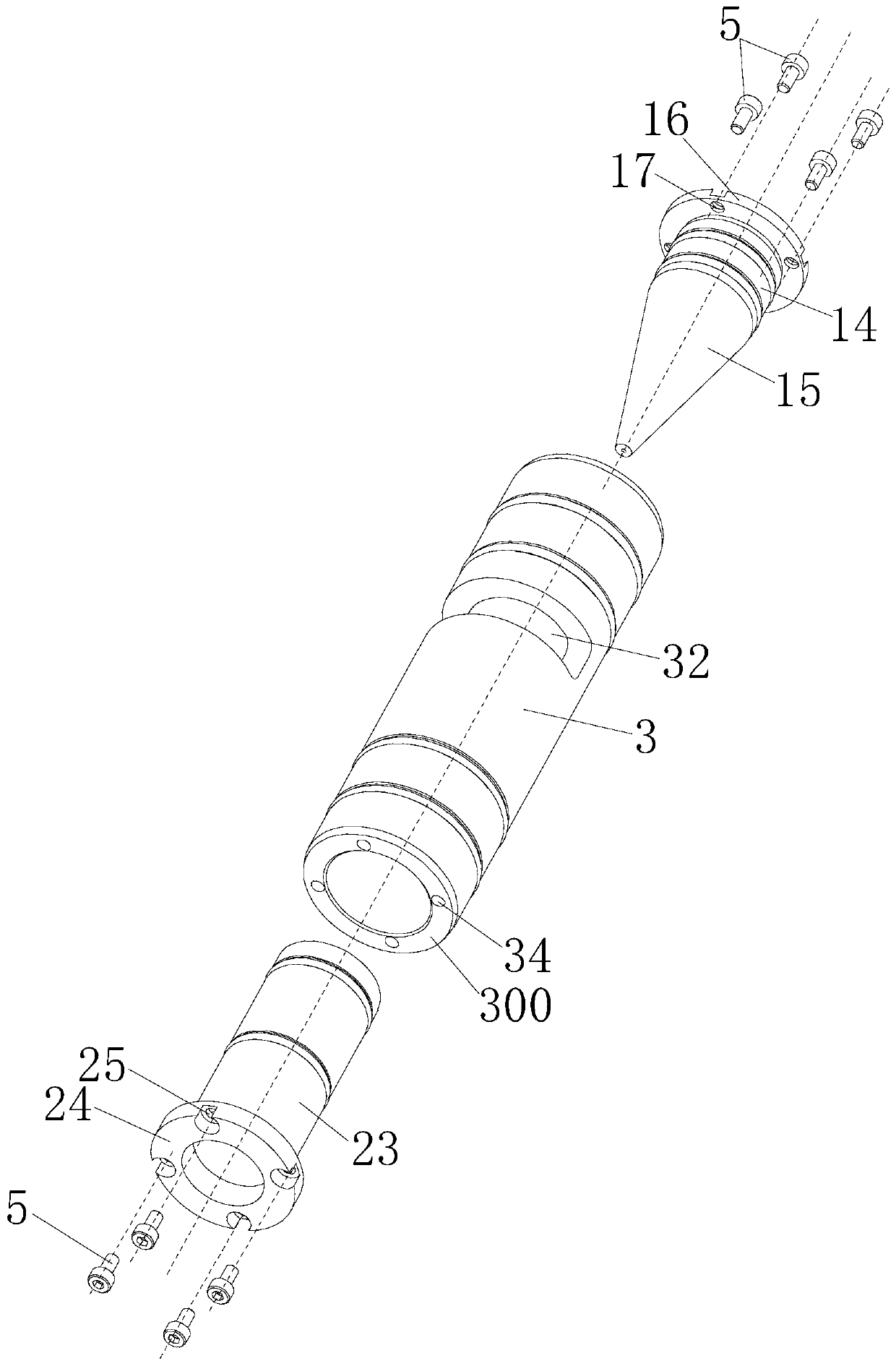

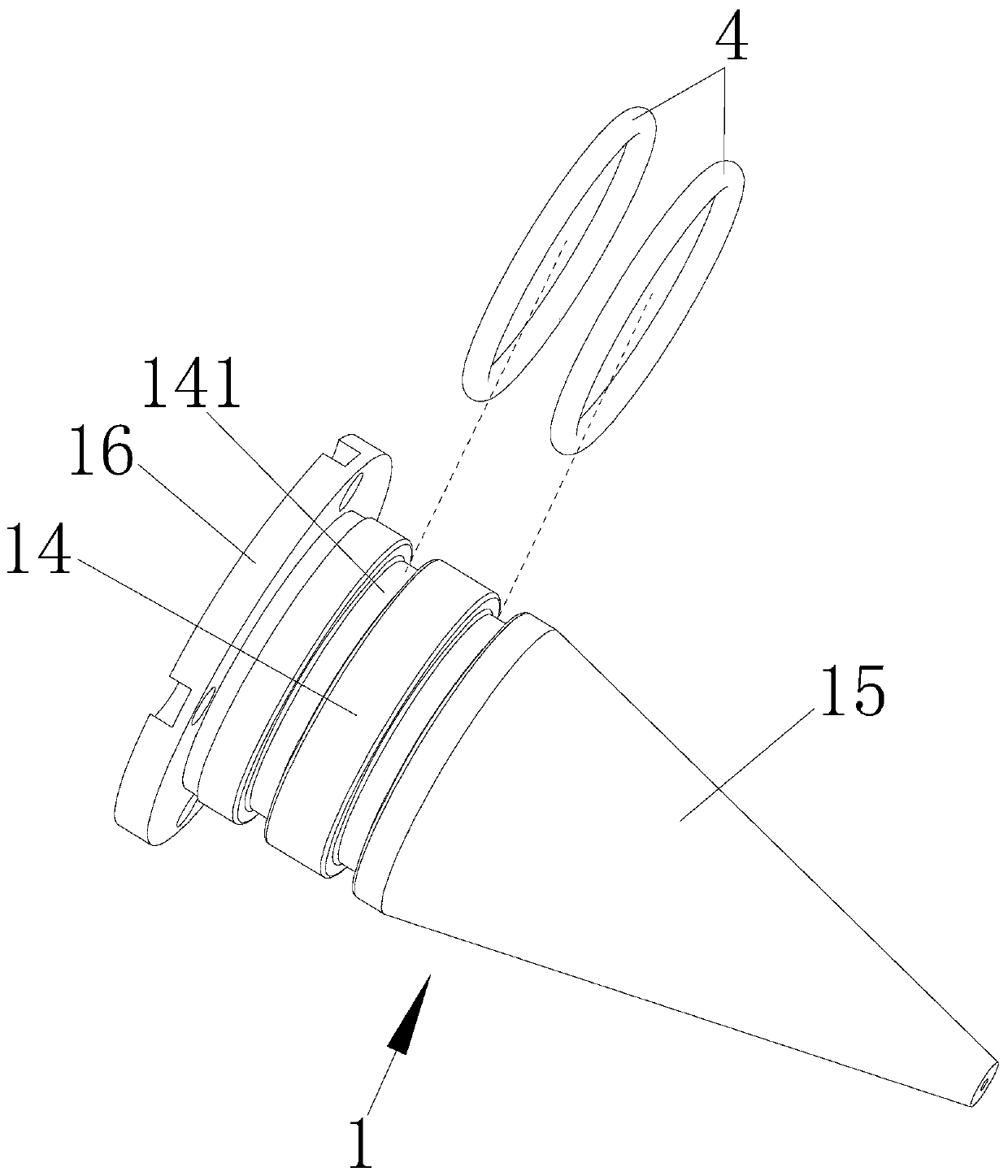

[0035] Such as Figure 1 to Figure 7 As shown, this embodiment provides an ejector, which is characterized in that it includes a nozzle 1, a mixing chamber 2, an ejection sleeve 3, an inner sealing ring 4 and a fastening screw 5, and the ejection sleeve 3 It is a cylinder, and a circular cavity 31 is formed in the middle of the injection sleeve 3. The nozzle 1 and the mixing chamber 2 are respectively set on the two ends of the injection sleeve 3; the inner sealing ring 4 is used between the mixing chamber 2 and the injection sleeve 3 Sealing, the nozzle 1 and the injection sleeve 3 are sealed with the inner sealing ring 4, and the fastening screw 5 installs and fixes the nozzle 1 and the mixing chamber 2 on the injection sleeve 3, and there is a gap on the wall surface in the middle of the injection sleeve 3 32 is used as the inlet of the fluid to be diverted. The first flow channel 11 is set in the middle of the nozzle 1 as a channel for the working high-pressure fluid. One ...

Embodiment 2

[0046] Such as Figure 8 As shown, a fuel cell hydrogen inlet adjustment hydrogen return device, including a block 100, a hydrogen inlet joint, a hydrogen return port joint, a hydrogen outlet joint, an injector 200 and a proportional regulating valve, and the injector 200 is installed In the block 100, it is characterized in that: the ejector 200 is any one of the ejector 200 described in the first embodiment above, and a circular cross-section pipe 101 is arranged inside the block 100, and the ejector 200 is nested Installed in the pipe 101 with a circular cross section, the outer sealing rings 6 at both ends of the outer surface of the injection sleeve 3 are pressed against the wall surface of the pipe 101 with a circular cross section to form a seal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com