Blade fault diagnosis test device based on visual information processing

A fault diagnosis and visual technology, applied in the direction of measuring devices, image data processing, testing of mechanical components, etc., can solve the problems of less research on real-time monitoring, achieve the effect of simple and convenient replacement and processing, and ensure accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

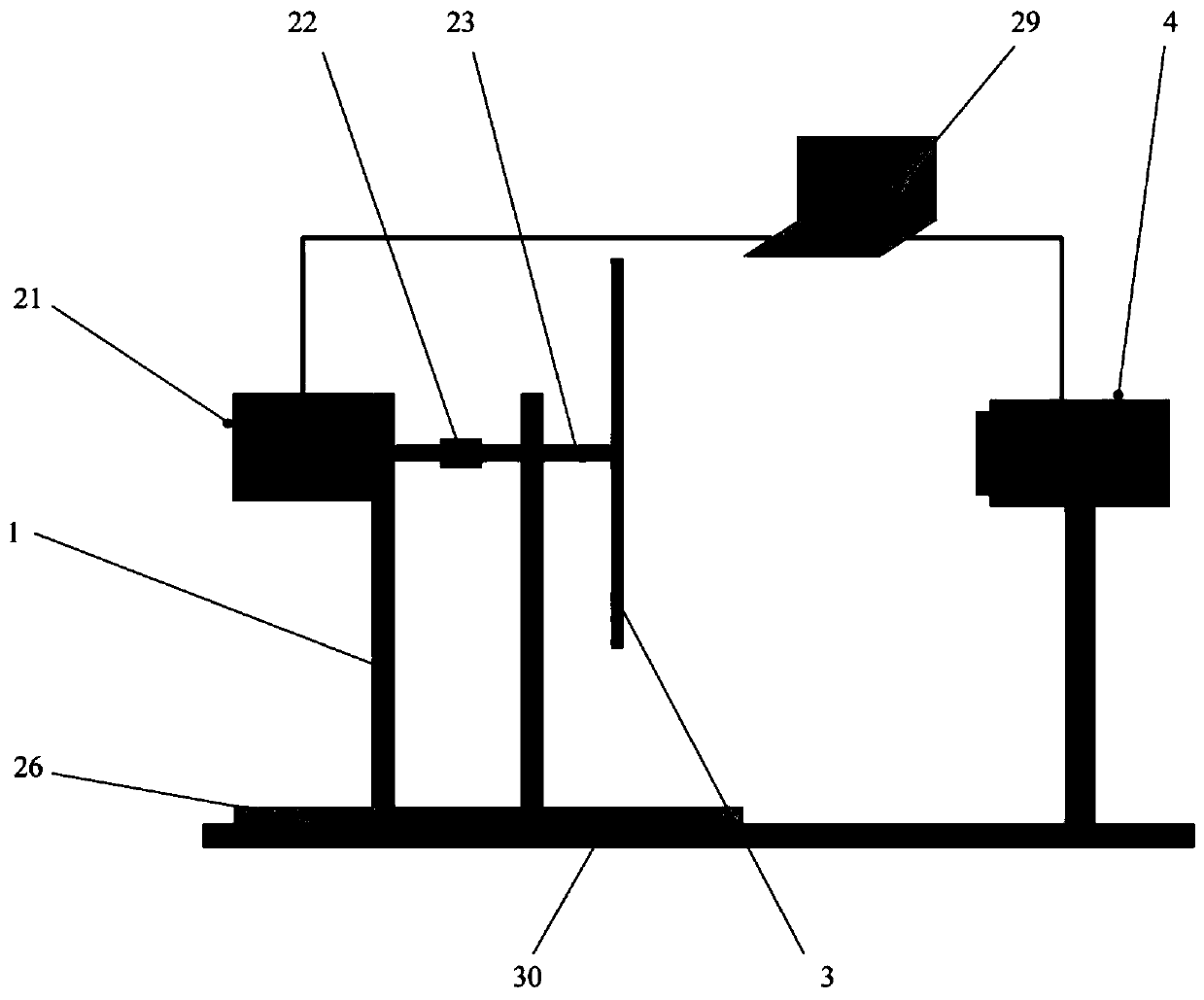

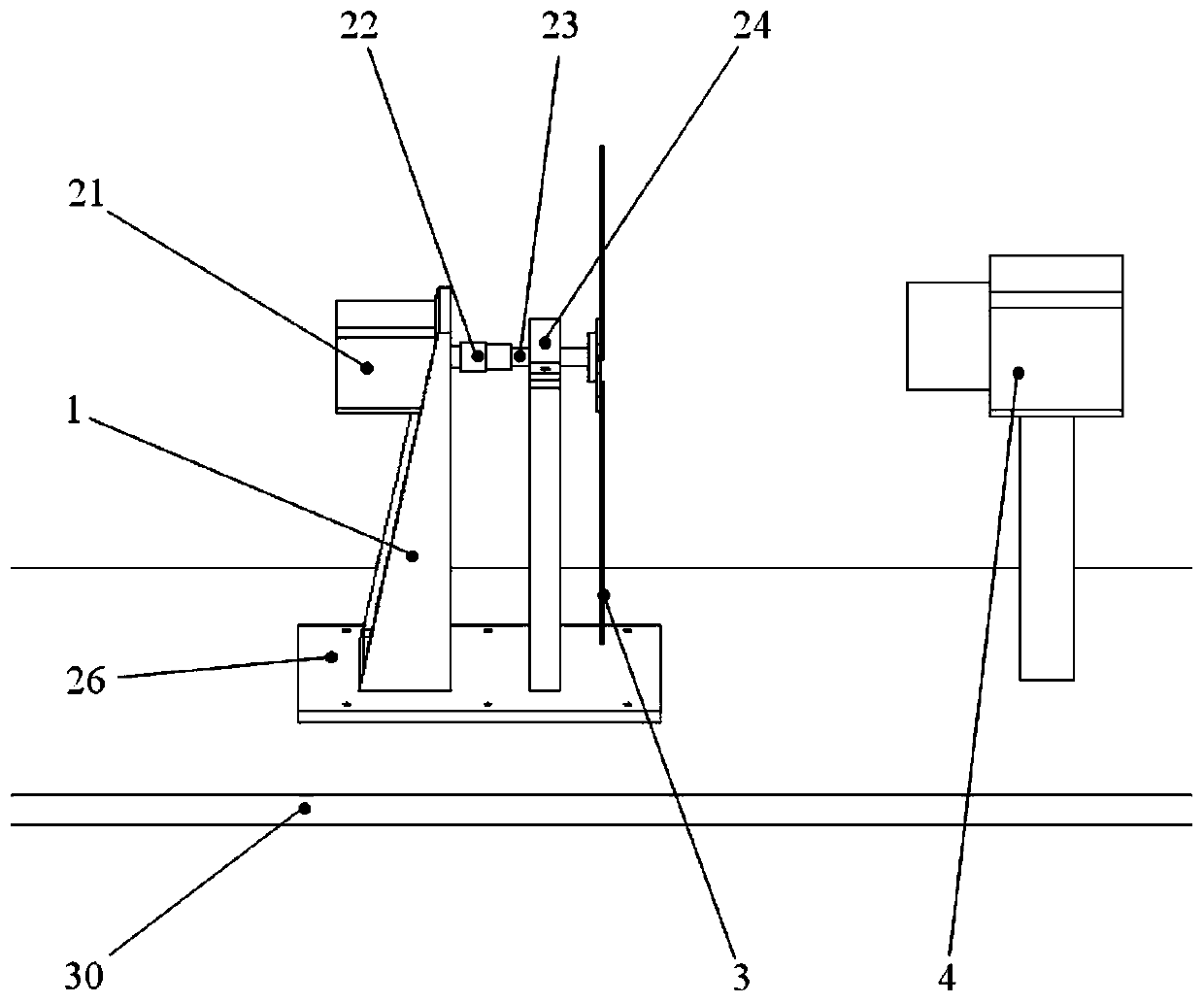

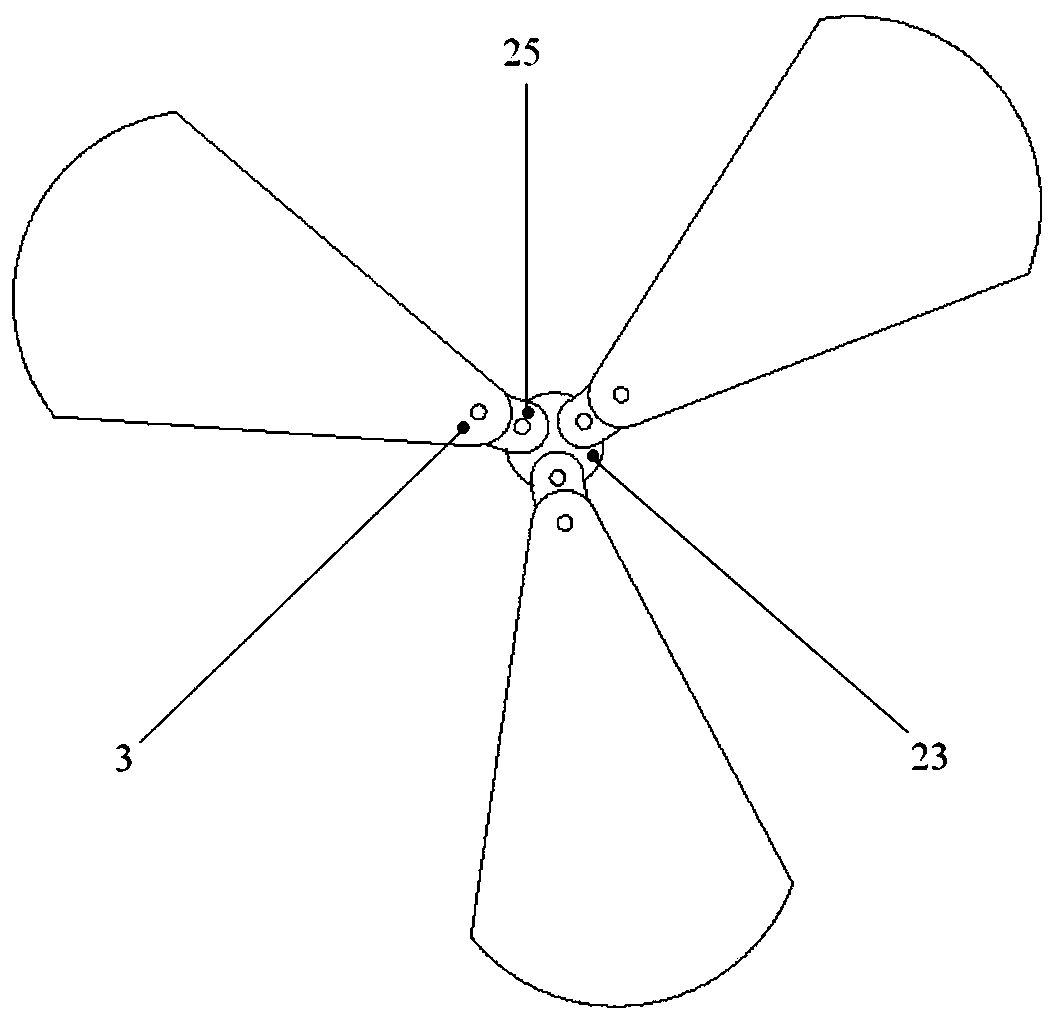

[0024] This embodiment is a blade fault diagnosis test device based on visual information processing.

[0025] Firstly, the rotating blades needed for the test are selected and pretreated according to the test requirements. Then connect the rotating blade to the rotating shaft through blade fasteners, confirm that all test devices are connected correctly and the wires are connected correctly, and the test device is firmly connected to the fixed table. Turn on the speed cameras and get ready to work. Start the servo motor, set the operating parameters of the servo motor; the servo motor drives the rotating shaft to rotate, and obtain the visual information of the surface of the rotating blade through the high-speed camera. Finally, use the computer to process the picture information obtained by the high-speed camera, and carry out fault diagnosis and analysis on the rotating blade.

[0026] refer to Figure 1 ~ Figure 3 , the present embodiment is based on the blade fault di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com