A kind of salt-free cold pad-batch dyeing method of unboiled bleached cotton fiber

A cold pad-batch dyeing and cotton fiber technology, which is applied in the field of cotton fiber printing and dyeing, can solve the problems of shortening the dyeing time of reactive dyes, consuming energy and water resources, and not dyeing cotton-type fabrics, so as to improve the fixing rate and dyeing rate , energy saving, high dyeing rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

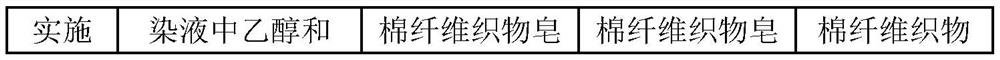

[0032] S1. Preparation of dye solution: put reactive red 195 and sodium carbonate in the mixed solution of ethanol and water, stir evenly to prepare dye solution, wherein the volume ratio of ethanol and water in the dye solution is 80%:20%, dye solution The concentration of reactive dyes in the medium is 5g / L, and the concentration of sodium carbonate is 25g / L;

[0033] S2. Padding dyeing solution: put the unboiled and bleached cotton yarn in the prepared dyeing solution, and pad for 30s at a temperature of 25°C. The excess rate of the unboiled and bleached cotton yarn after liquid is 70%;

[0034] S3. Rolling and stacking: the unboiled and bleached cotton yarn dyed in step S2 is rolled on a coiling machine, and the rolled unboiled and bleached cotton yarn is wrapped in a plastic film and then rotated and stacked, wherein the stacking temperature is 35 ° C. The stacking time is 8h, and the rotation speed is 5r / min;

[0035] S4. Washing: soaping, hot water washing, cold water...

Embodiment 6-10

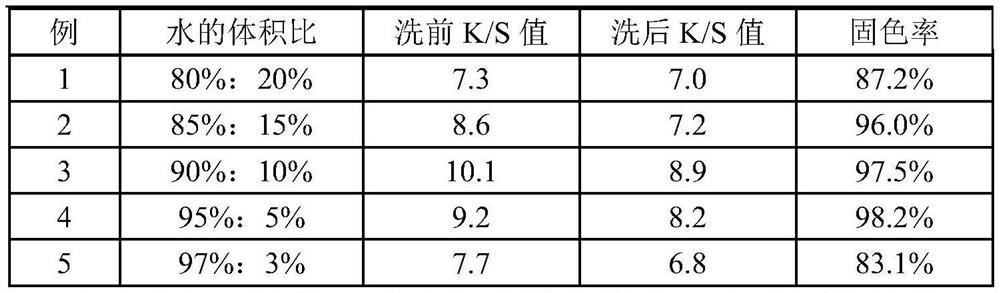

[0042] On the basis of embodiment 1, wherein the volume ratio of ethanol and water is 85%:15% in the dye liquor, the concentration of reactive dyestuff is 15g / L in the dye liquor, alkaline substance is sodium carbonate, and the concentration of sodium carbonate is 20% ~40g / L, the pad dyeing solution is padded for 17s at a temperature of 27°C, the liquor ratio is 1:25, the excess rate of unboiled and bleached cotton sliver after padding and dyeing solution is 90%, rolled and stacked The best conditions are that the stacking temperature is 30°C, the stacking time is 16h, and the rotation speed is 7r / min.

[0043] In consideration of the influence of the concentration of alkaline substances in the dyeing liquor on the color fixation rate, under the condition that other conditions remain unchanged, by changing the concentration of alkaline substances, the variation law of the color fixation rate of unboiled and bleached cotton sliver is investigated, embodiment 6- 10, as shown in ...

Embodiment 11-15

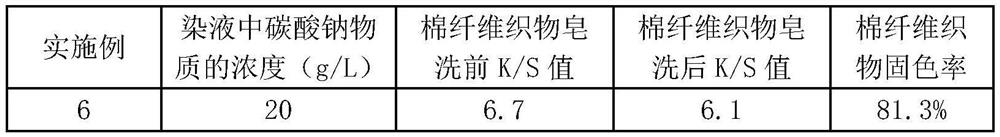

[0049] On the basis of Example 1, wherein the volume ratio of ethanol and water in the dye liquor is 95%: 5%, the concentration of reactive dyestuff is 25g / L in the dye liquor, alkaline substance is sodium bicarbonate, the concentration of sodium bicarbonate The padding solution is 30g / L, the padding solution is padded for 25s at a temperature of 20-35°C, the bath ratio is 1:30, the excess rate of the unboiled and bleached cotton sliver after the padding solution is 100%, and the rolling The stacking conditions are as follows: the stacking temperature is 30° C., the stacking time is 8 hours, and the rotation speed is 10 r / min.

[0050] In consideration of the influence of the temperature of the pad dyeing solution on the color fixation rate, under the condition that other conditions remain unchanged, by changing the padding temperature, the change law of the color fixation rate of unboiled and bleached cotton sliver is investigated. Examples 11-15, such as Table 3 shows.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com