Preparation method and application of moringa oleifera fermentation liquor and biological cellulose membrane

A technology of biological cellulose and fermented products, which is applied in the field of preparation of Moringa oleifera fermentation liquid and biological cellulose film, can solve the problems of single structure and poor functionality, and achieve the effects of broad application prospects, strong water absorption and water holding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1), preparation medium

[0048]Moringa leaf medium formula, prepare 1000mL medium, wherein the C source is glucose, weigh 40g, add 500mL deionized water, and put it in a No. 1 Erlenmeyer flask; two N sources are Moringa leaf and Amano protease (CAS No.9074 -07-1) Weigh 5g respectively, add 500mL of deionized water, in No. Put it in a sterilizer, set it at 115°C, keep the high temperature for 20min, and sterilize for 1.5h. After the sterilization, the culture medium and pipette tips were placed in an oven at 66°C, dried to prevent water pollution, and then used.

[0049] 2), activation / inoculation

[0050] (1), tray sterilization:

[0051] There are two ways to sterilize trays: immersion in hypochlorous acid solution, which is to soak the tray in 5.5%-6.5% hypochlorous acid solution for 0.5h; dry heat sterilization, which is to place the tray in an oven at 160°C , dry for 1h. The residual ClO- in the tray of the first method will have an impact on the strains, and t...

Embodiment 2

[0065] Using the Moringa oleifera leaf fermentation broth and biocellulose film produced by the fermentation described in Example 1 as raw materials to prepare cosmetics, the formula is shown in Table 1:

[0066] Table 1 Cosmetic formula

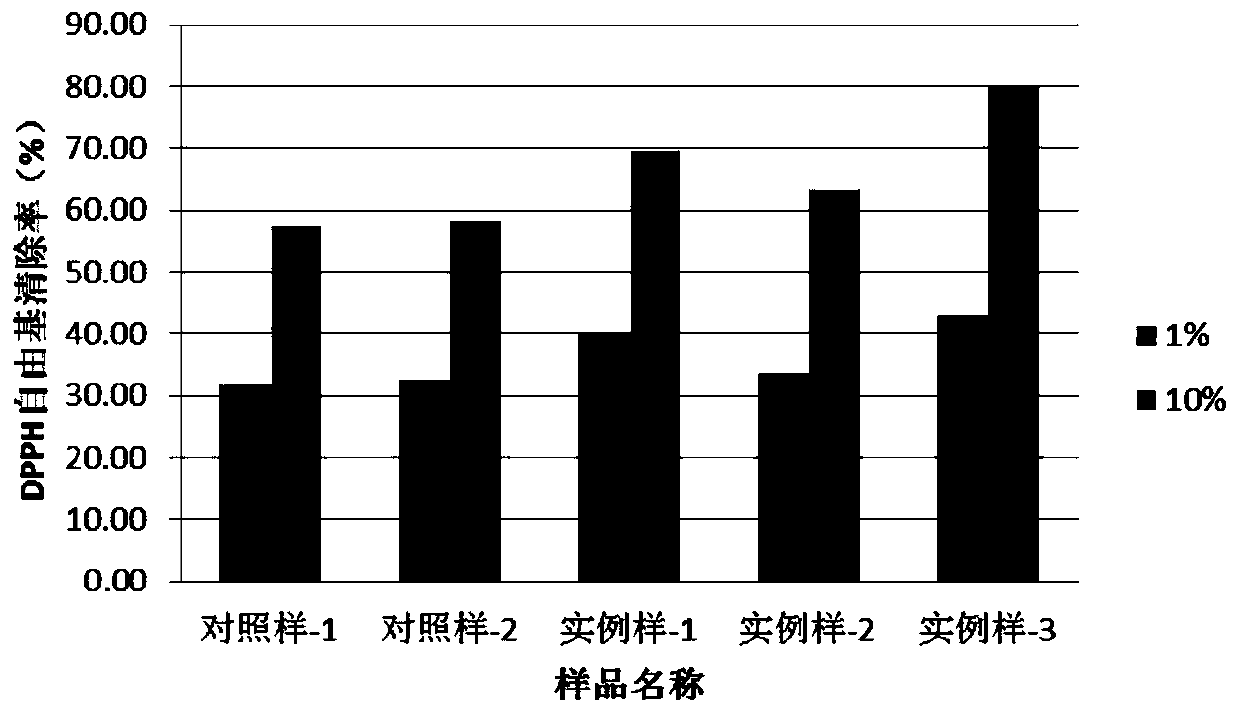

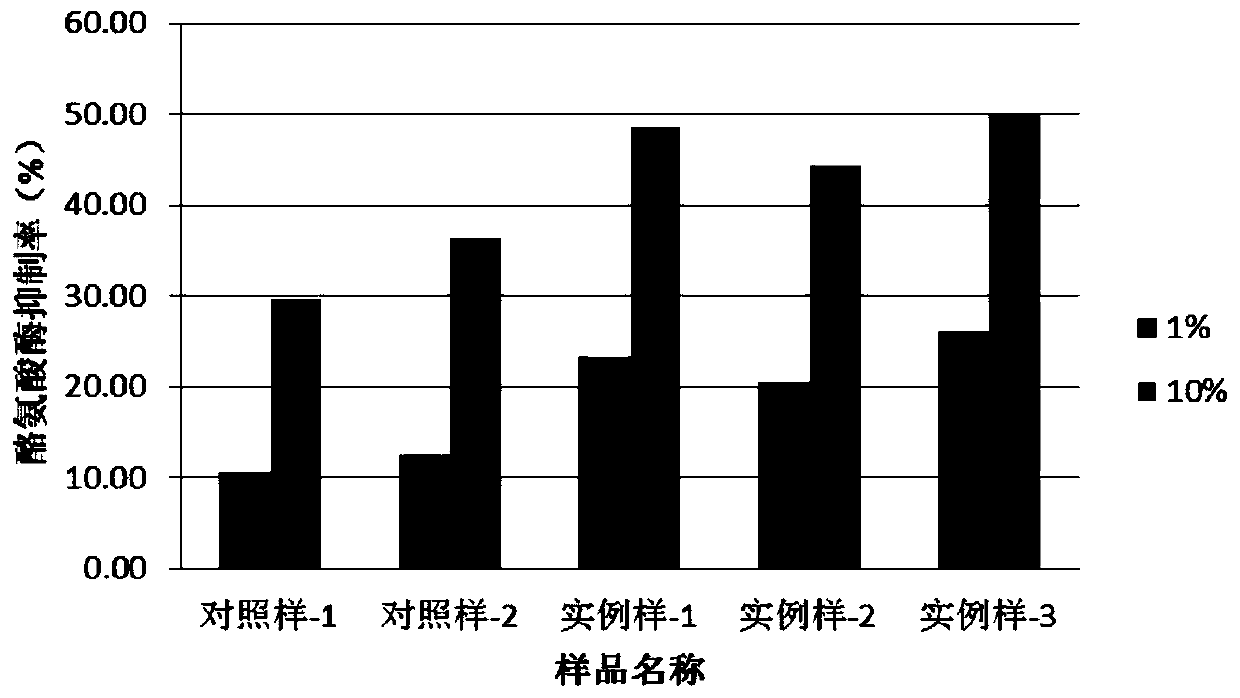

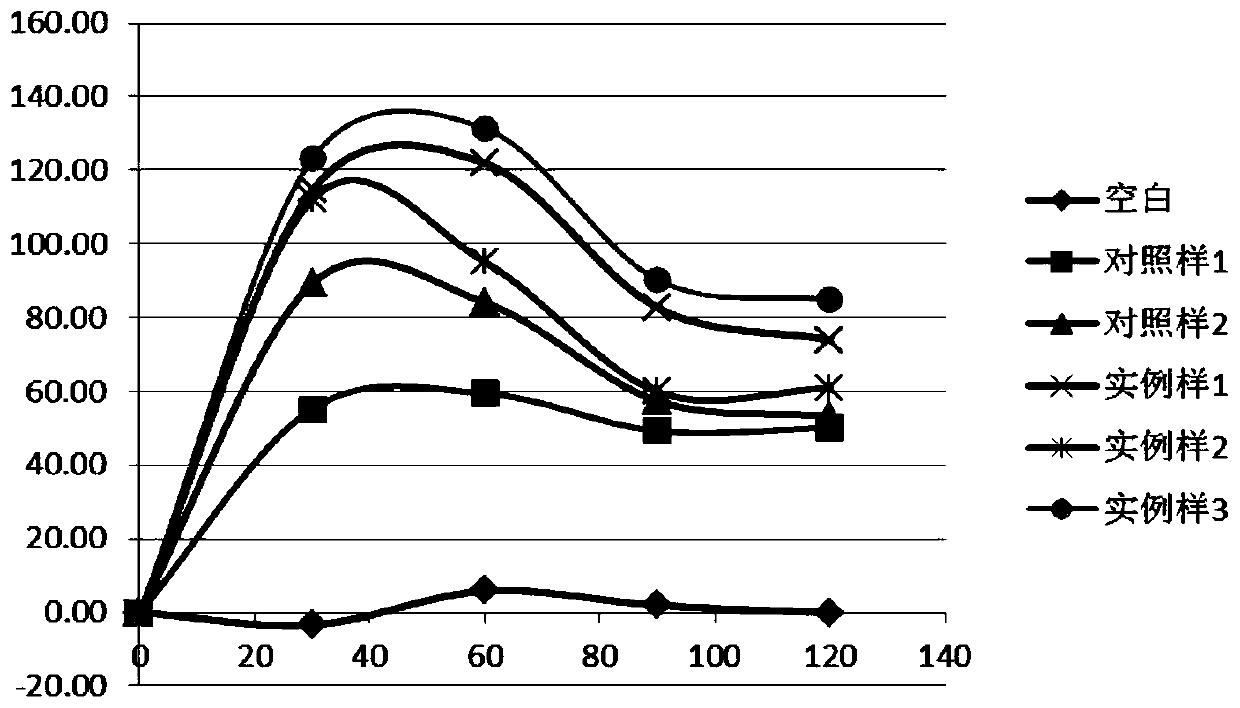

[0067] components Control 1 Control 2 Example 1 Example 2 Example 3 glycerin 8.0 8.0 8.0 8.0 8.0 1,3-Butanediol 1.0 1.0 1.0 1.0 1.0 Pentylene glycol 1.0 1.0 1.0 1.0 1.0 oligomeric hyaluronic acid 0.1 0.1 0.1 0.1 0.1 PHL 1.0 1.0 1.0 1.0 1.0 xanthan gum 0.1 0.1 0.1 0.1 0.1 Moringa Leaf Fermentation Liquid -- 28.5 60.0 40.0 88.8 water 88.8 60.3 28.8 48.8 0

[0068] Its preparation process is described as follows:

[0069] 1) Weigh glycerin, propylene glycol, butylene glycol, oligomeric hyaluronic acid, and xanthan gum according to the formula ratio, add deionized water, heat to 70-75°C, and stir at 7000r / min-9000r / min for 30min, until dissol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com