Method for promoting microalgae growth and grease accumulation in BG-11 culture medium

A technology of BG-11 and oil accumulation, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as environmental pollution and resource waste, achieve environmental protection, solve environmental problems, and increase biomass production rate and the effect of oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

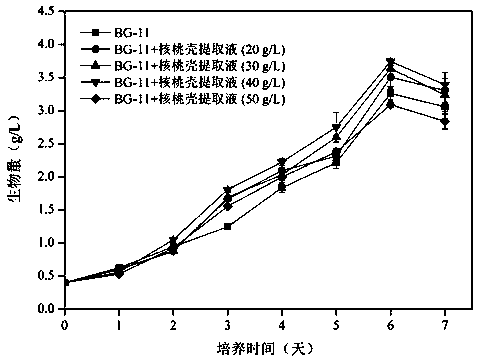

Embodiment 1

[0025] (1) Preparation of medium: first prepare BG-11 medium, adjust the pH value between 6.8-7.0 with HCl solution, sterilize at 121°C for 20 minutes; add water 9.5 times the mass of walnut shells, and store at 95°C Incubate for 240 min, adjust the pH value between 6.8-7.0 with NaOH solution, obtain walnut shell extract with a walnut shell extract concentration of 100 g / L, subpackage, and sterilize at 121°C for 20 min; mix the walnut shell extract with BG- 11 was mixed in the reactor, and the concentration of walnut shell extract in the medium after mixing with BG-11 was 20g / L.

[0026] (2) Cultivation of microalgae: insert oil-producing microalgae into the above-mentioned prepared medium, and pass in CO 2 -Air mixed gas, light culture, the initial inoculum volume is 0.4 g / L, the light intensity is 6500 lux, and CO is introduced 2 - CO in the air mixture 2 The content is 12%, and the culture temperature is 25±1℃.

[0027] (3) Extraction of oil from microalgae: culture the ...

Embodiment 2

[0030] (1) Preparation of medium: first prepare BG-11 medium, adjust the pH value between 6.8-7.0 with HCl, and sterilize at 121 °C for 20 minutes. Add water with 9.5 times the mass of walnut shells, incubate at 95°C for 240 minutes, adjust the pH value between 6.8-7.0 with NaOH solution, and obtain walnut shell extracts with a walnut shell extract concentration of 100 g / L. Sterilize at ℃ for 20 min. The walnut shell extract and BG-11 were mixed in the reactor, and the concentration of the walnut shell extract in the medium after mixing with BG-11 was 30g / L.

[0031] (2) Cultivation of microalgae: insert oil-producing microalgae into the above-mentioned prepared medium, and pass in CO 2 - Air mixed gas, light culture, the initial inoculum volume is 0.4 g / L, the light intensity is 6700lux, and CO is introduced 2 - CO in the air mixture 2 The content is 12%, and the culture temperature is 25±1℃.

[0032] (3) Extraction of oil from microalgae: culture the microalgae to the la...

Embodiment 3

[0035] (1) Preparation of medium: first prepare BG-11 medium, adjust the pH value between 6.8-7.0 with HCl solution, and sterilize at 121 °C for 20 min. Add water with 9.5 times the mass of walnut shells, incubate at 95°C for 240 minutes, adjust the pH value between 6.8-7.0 with NaOH solution, and obtain walnut shell extracts with a walnut shell extract concentration of 100 g / L. Sterilize at ℃ for 20 min. The walnut shell extract and BG-11 were mixed in the reactor, and the concentration of the walnut shell extract in the medium after mixing with BG-11 was 40g / L.

[0036] (2) Cultivation of microalgae: insert oil-producing microalgae into the above-mentioned prepared medium, and pass in CO 2-Air mixed gas, light culture, the initial inoculation amount is 0.4 g / L, the light intensity is 7000 lux, and CO is introduced 2 - CO in the air mixture 2 The content is 12%, and the culture temperature is 25±1℃.

[0037] (3) Extraction of oil from microalgae: culture the microalgae to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com