Controlled-release fertilizer, and preparation method and application thereof

A technology of controlled-release fertilizers and inorganic fertilizers, applied in the direction of fertilization methods, applications, fertilizer mixtures, etc., can solve the problems of controlled-release effects, poor coating processing performance, etc., and achieve continuous and stable continuous coating production, small adhesion process, and The effect of improved controlled release performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

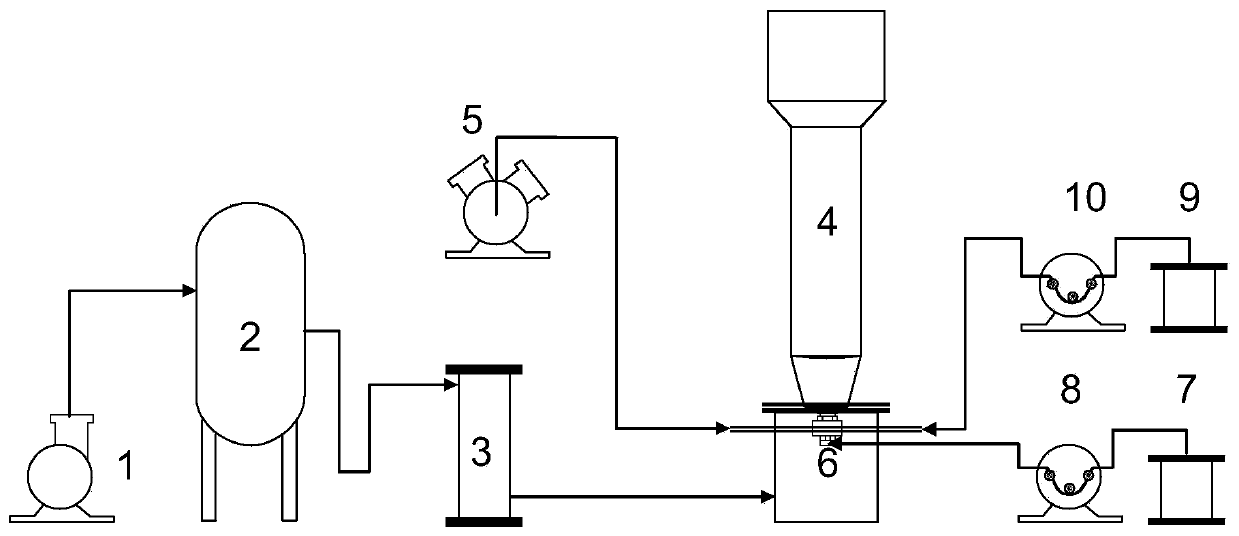

Method used

Image

Examples

Embodiment 1

[0070] Component A: modified castor oil (CO is 100%), stannous octoate 0.05%, paraffin 1%, R value 1.12;

[0071] Component B: diphenylmethane diisocyanate.

Embodiment 2

[0073] Component A: modified castor oil (90% CO), stannous octoate 0.05%, paraffin 1%, R value 1.12; BDO 10%;

[0074] Component B: diphenylmethane diisocyanate.

Embodiment 3

[0076] Component A: modified castor oil (90% CO), 0.05% stannous octoate, 1% paraffin, R value 1.12; PDO 10%;

[0077] Component B: diphenylmethane diisocyanate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com