Composite radiation refrigeration film

A composite radiation and solar radiation technology, applied in refrigerators, refrigeration and liquefaction, synthetic resin layered products, etc., can solve the problem that the cooling effect needs to be further improved, and achieve the effect of improving the cooling effect and increasing the emissivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

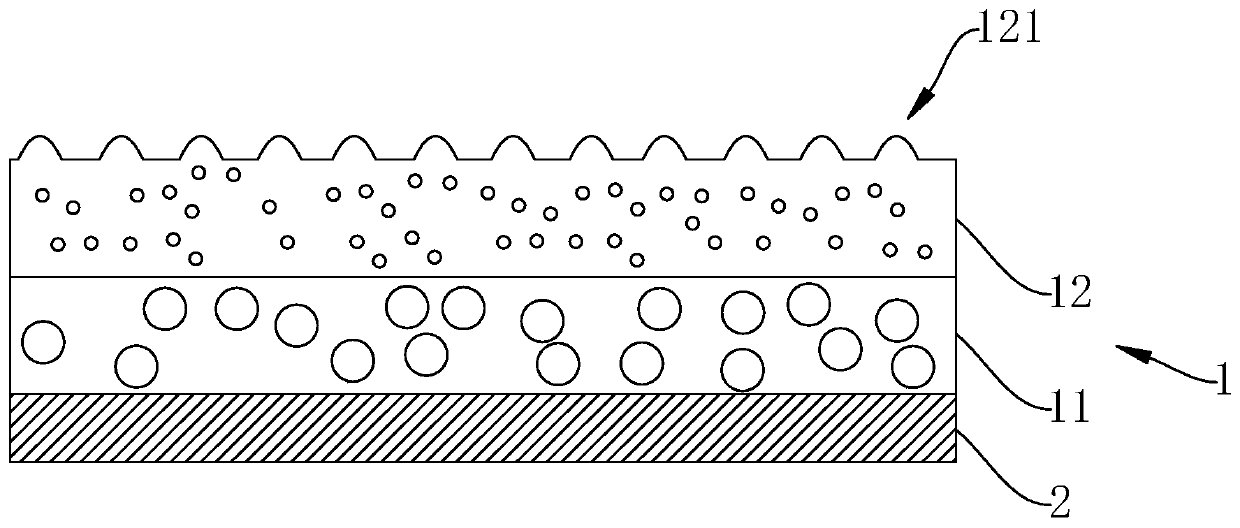

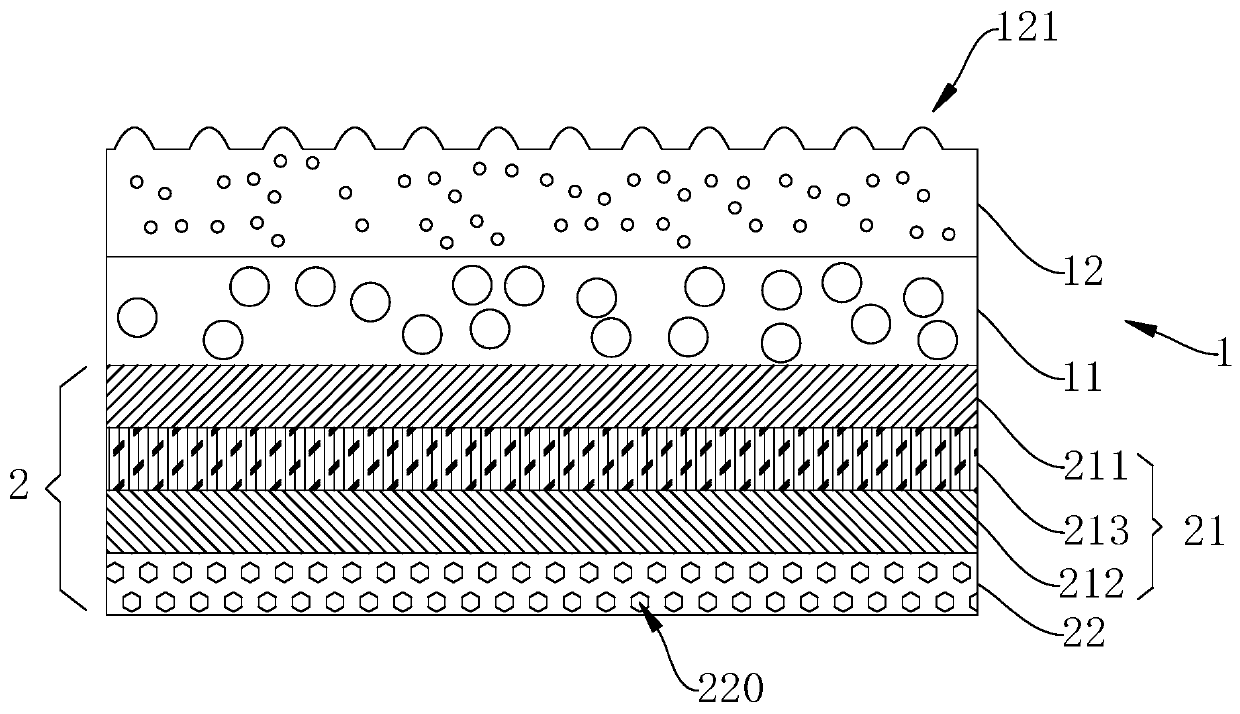

[0069] A composite radiant refrigeration film, comprising a second emitting layer, a first emitting layer, and a metal reflective layer sequentially arranged from top to bottom, wherein:

[0070] The thickness of the second emission layer is 20μm. The second emission layer includes PET polymer and hollow second cells dispersed in the PET polymer. The average diameter of the second cells is 20 nm. The volume fraction in the emission layer is 3%;

[0071] The thickness of the first emission layer is 5 μm. The first emission layer includes TPX polymer and hollow first cells. The average diameter of the first cells is 5 μm. The volume fraction of the first cells in the first emission layer is 15%;

[0072] The thickness of the metal reflection layer is 200 nm, and the metal reflection layer is a silver layer plated on the first emission layer.

Embodiment 2

[0074] A composite radiant refrigeration film, comprising a second emitting layer, a first emitting layer, and a metal reflective layer sequentially arranged from top to bottom, wherein:

[0075] The thickness of the second emission layer is 50μm, and the second emission layer includes PET polymer and SiO 2 Particles, SiO 2 The average particle size of the particles is 200 nm, SiO 2 The volume fraction of particles in the second emitting layer is 20%;

[0076] The thickness of the first emission layer is 100 μm, the first emission layer includes ABS polymer and ceramic beads, the average particle size of the ceramic beads is 10 μm, and the volume fraction of the ceramic beads in the first emission layer is 10%;

[0077] The thickness of the metal reflection layer is 150 nm, and the metal reflection layer is an aluminum layer plated on the first emission layer.

Embodiment 3

[0079] The difference between the composite radiant refrigeration film of Example 3 and Example 1 is that: the outer surface of the second emitting layer of Example 3 has a convex microstructure, and the convex microstructure is embossed by a roller with a microstructure on the surface. Formed, the size of the raised microstructure is on the order of microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com