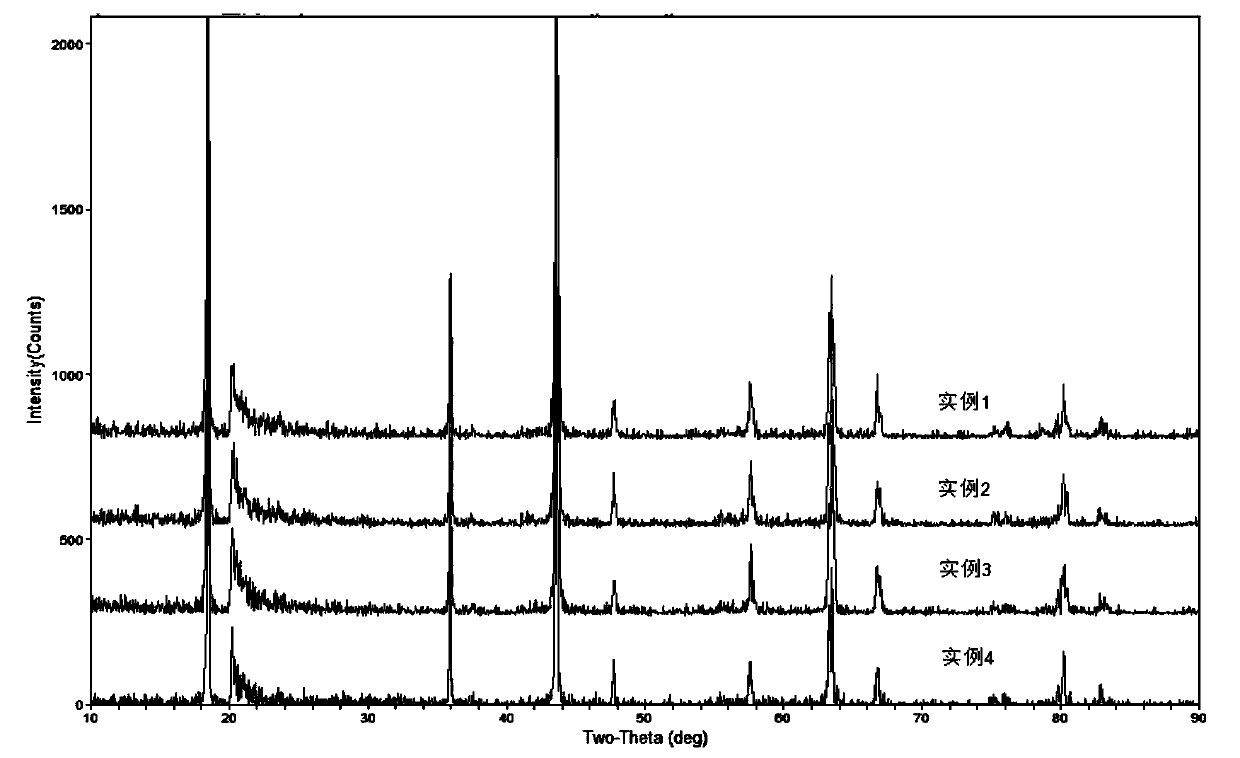

Preparation method of powder type high-capacity titanium-based lithium ion exchanger

A technology of lithium ions and exchangers, which is applied in the field of preparation of inorganic non-metallic materials, can solve the problems of unfavorable industrialization, high cost, and difficulty in mass production, so as to avoid the loss of lithium sources, reduce sanding treatment, and reduce raw material costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

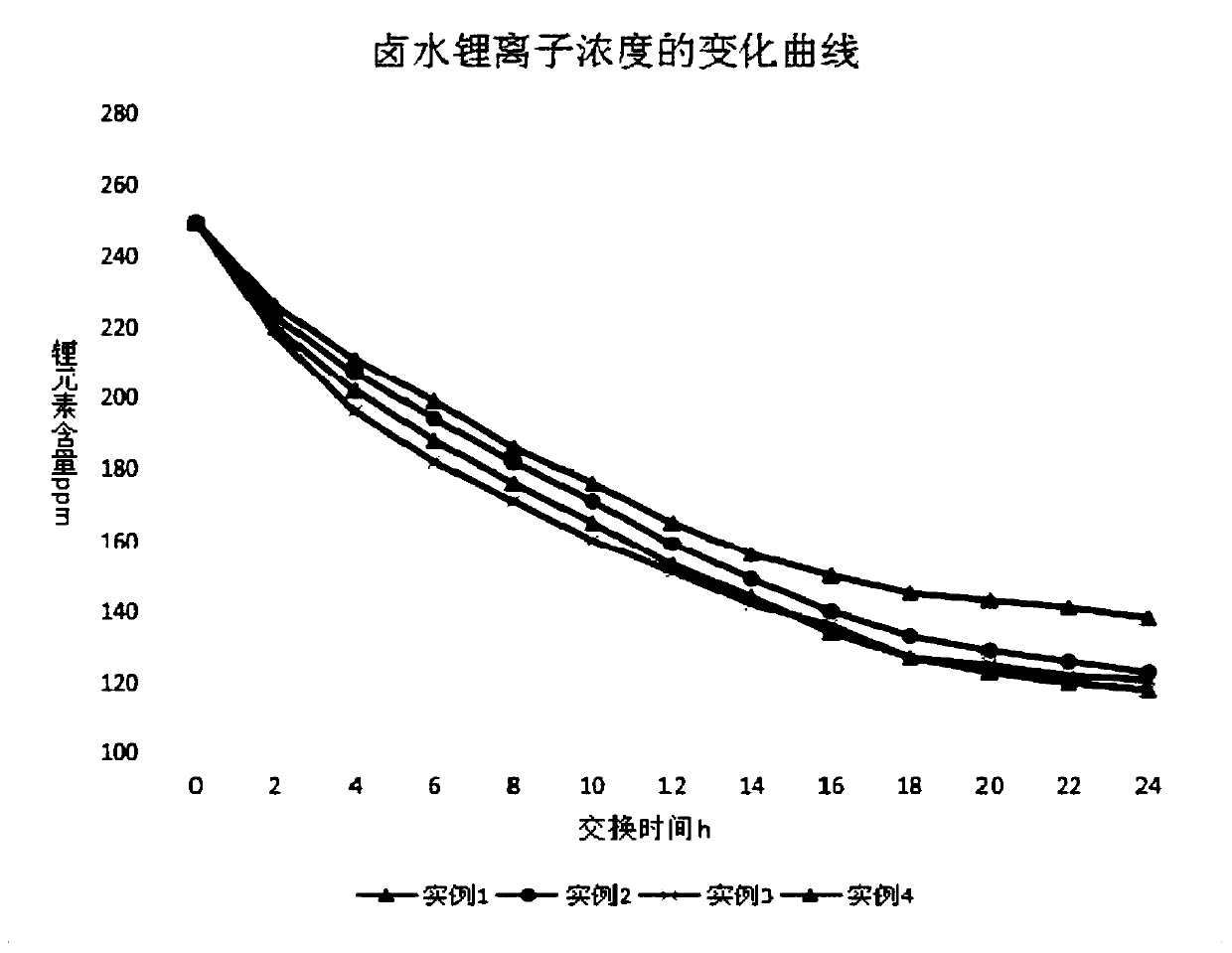

Embodiment 1

[0036] A preparation method of a powder type high-capacity titanium series lithium ion exchanger, comprising the following steps:

[0037] Step 1. Take the sulfuric acid method titanium dioxide production process and take the second washing qualified metatitanic acid and beat it with deionized water to TiO 2 The concentration was 300g / L to obtain slurry A; the slurry A was heated to 70°C, and 100g / L sodium hydroxide solution was added dropwise under stirring to control the pH range of 9.5, and the slurry B was obtained after aging for 2 hours;

[0038] Step 2. Slowly add 10% hydrochloric acid solution to the slurry B under stirring to control the pH range to 5.0, and mature for 2 hours to obtain slurry C;

[0039] Step 3, slurry C is filtered, washed with water until the conductivity of the filtrate is less than 50 μS / cm, and the filter cake is made of TiO by adding saturated lithium carbonate solution 2 Slurry D with a concentration of 400g / L;

[0040] Step 4, beating Lithi...

Embodiment 2

[0048] A preparation method of a powder type high-capacity titanium series lithium ion exchanger, comprising the following steps:

[0049] Step 1. Take the sulfuric acid method titanium dioxide production process and take the second washing qualified metatitanic acid and beat it with deionized water to TiO 2 The concentration was 200g / L to obtain slurry A; the slurry A was heated to 65°C, and 100g / L potassium hydroxide solution was added dropwise under stirring to control the pH range of 8.5, and the slurry B was obtained after aging for 3 hours;

[0050] Step 2. Slowly add 10% sulfuric acid solution to the slurry B under stirring to control the pH range to 6.0, and mature for 3 hours to obtain slurry C;

[0051] Step 3, slurry C is filtered, washed with water until the conductivity of the filtrate is less than 50 μS / cm, and the filter cake is made of TiO by adding saturated lithium carbonate solution 2 Slurry D with a concentration of 350g / L;

[0052] Step 4, beating Lithiu...

Embodiment 3

[0060] A preparation method of a powder type high-capacity titanium series lithium ion exchanger, comprising the following steps:

[0061] Step 1. Take the sulfuric acid method titanium dioxide production process and take the second washing qualified metatitanic acid and beat it with deionized water to TiO 2 The concentration was 300g / L to obtain slurry A; the slurry A was heated to 70°C, and 100g / L ammonia solution was added dropwise under stirring to control the pH range of 8.0, and the slurry B was obtained after aging for 2 hours;

[0062] Step 2. Slowly add 10% oxalic acid solution to the slurry B under stirring to control the pH range to 7.0, and mature for 2 hours to obtain slurry C;

[0063] Step 3, slurry C is filtered, washed with water until the conductivity of the filtrate is less than 50 μS / cm, and the filter cake is made of TiO by adding saturated lithium carbonate solution 2 Slurry D with a concentration of 400g / L;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com