Multifunctional straw returning machine

A multi-functional, straw technology, used in harvesters, crop processors, agricultural machinery and implements, etc., can solve the problems of single structure and poor applicability, and achieve the effect of increasing applicability and eliminating dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

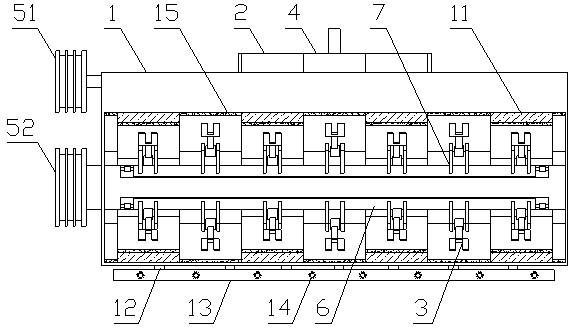

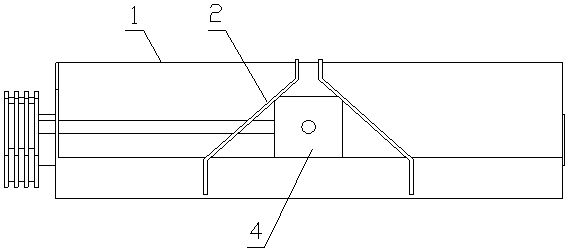

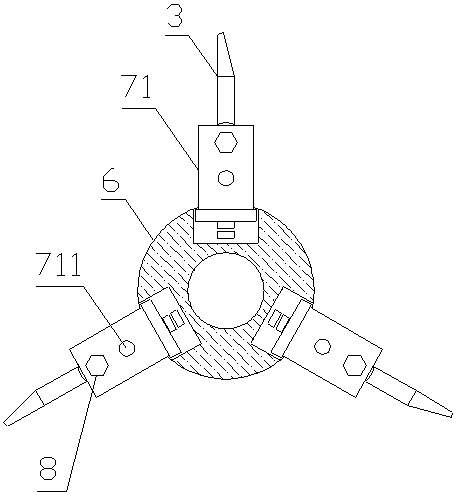

[0025] Example: such as figure 1 , figure 2 As shown, a multi-functional straw returning machine includes a machine body 1, a draw bar 2 and a crushing knife 3. A gearbox 4 is arranged in the middle of the inner surface of the machine body 1. There are two draw bars 2, which are symmetrical Set on both sides of the gearbox 4, the left end of the body 1 is provided with a pulley 5, the pulley 5 includes a pulley a51 and a pulley b52, the pulley a51 and the pulley b52 are connected to each other through a V-belt, and the pulley a51 passes through a rotating shaft Connected with the gearbox 4, the body 1 is provided with a rotating shaft 6, and the two ends of the rotating shaft 6 are respectively connected to the body 1 through bearings, wherein the left end of the rotating shaft 6 protrudes to the outside of the body 1 and is fixed to the wheel b52 Socketing, the outer surface of the rotating shaft 6 is uniformly provided with a tool holder 7 along its circumferential directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com