Novel radio frequency electron accelerator structure

An electron accelerator and radio frequency technology, applied in the direction of electrical components, accelerators, etc., can solve the problems of difficult processing and assembly, complex structure, inconvenient use, etc., and achieve the effect of reducing processing difficulty and optimizing design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

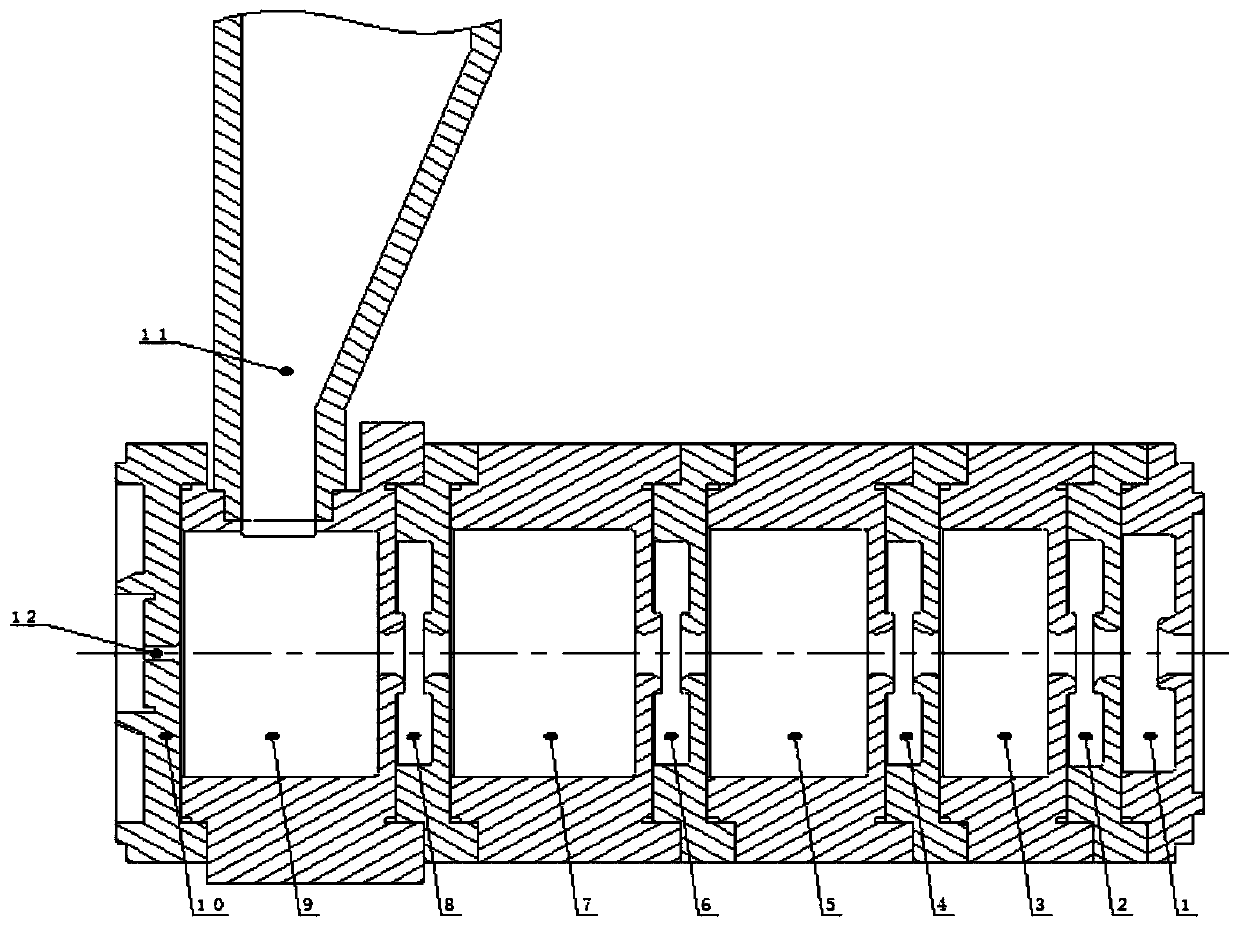

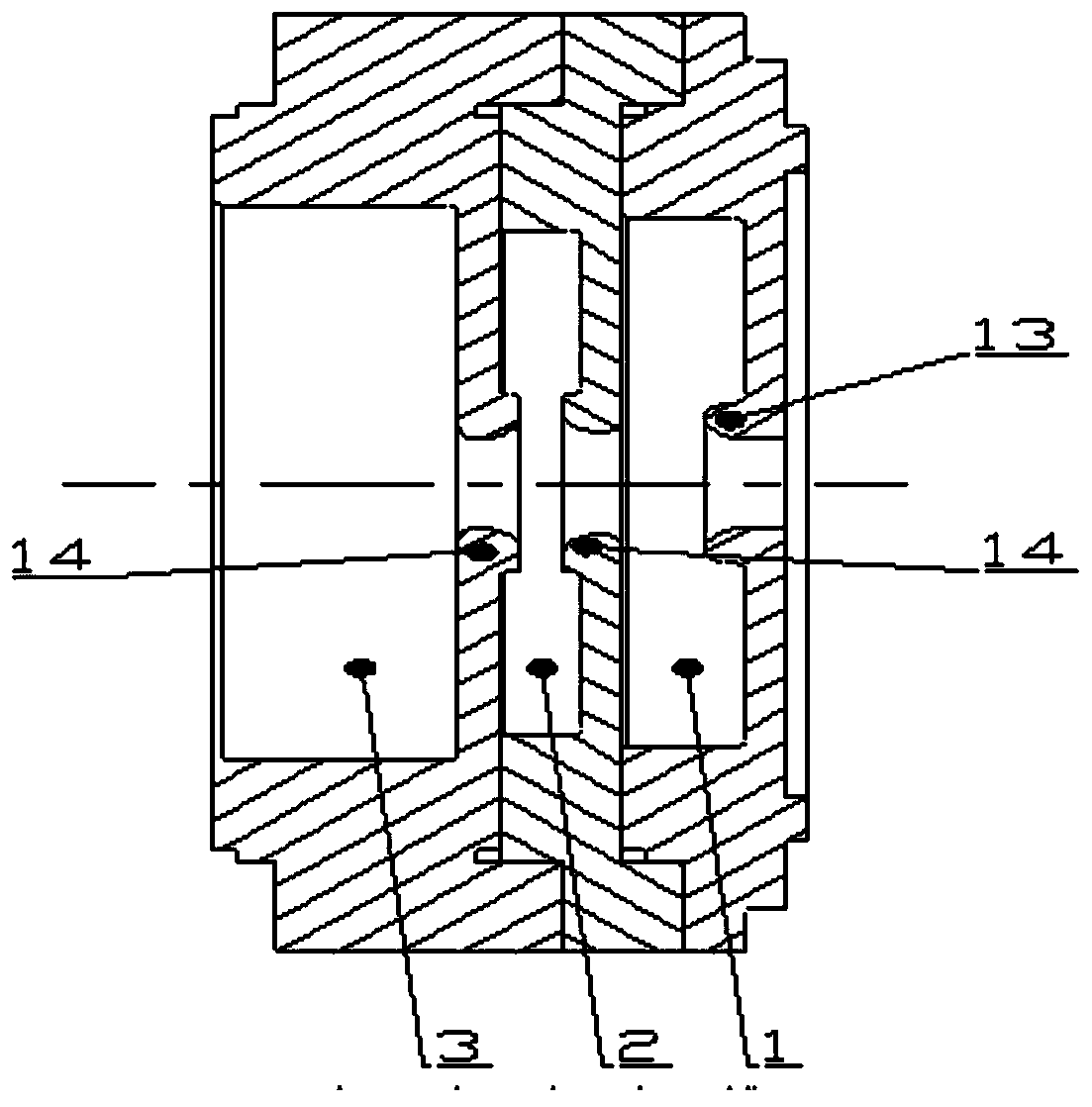

[0027] like Figure 1-3 Shown: This embodiment takes 5 accelerating cavities and 4 coupling cavities as an example for illustration, the actual number can be adjusted by those skilled in the art as needed. In this embodiment, the five accelerating chambers are respectively named as accelerating chamber A1, accelerating chamber A2, accelerating chamber A3, accelerating chamber A4, and accelerating chamber A5. The cavities are respectively named coupling cavity C1, coupling cavity C2, coupling cavity C3 and coupling cavity C4, and the numbers in the figure are 2, 4, 6, and 8, respectively.

[0028] Firstly, the accelerating chambers A1-A5 and the coupling chambers C1-C4 are assembled alternately, and then the sealing plate 10 is designed on the axial end surface of the accelerating chamber A5. Beam flow holes 12 are all designed on the axial end faces of the acceleration cavity, the coupling cavity and the sealing plate, and the center of the holes of these beam flow holes are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com