Starting control circuit of direct-current oil pump motor and control method of starting control circuit

An oil pump motor and starting control technology, which is applied to the starter of a single DC motor, motor generator/starter, etc., can solve the problems of large starting current and large impact on equipment, and achieve the effect of simple circuit and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

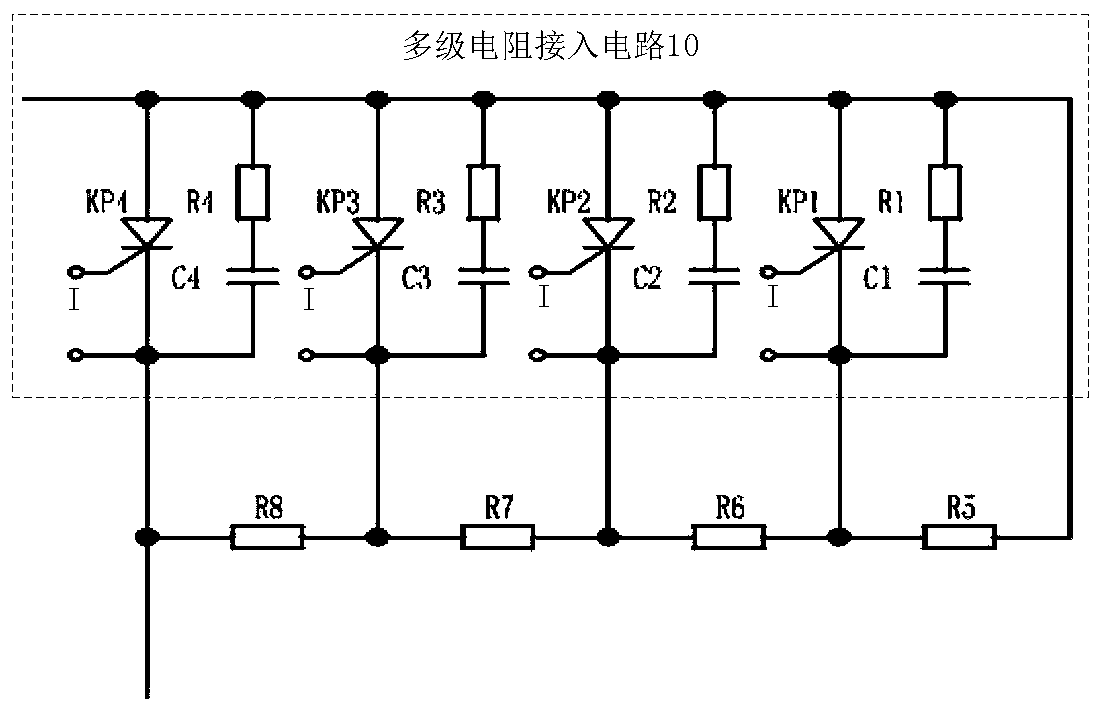

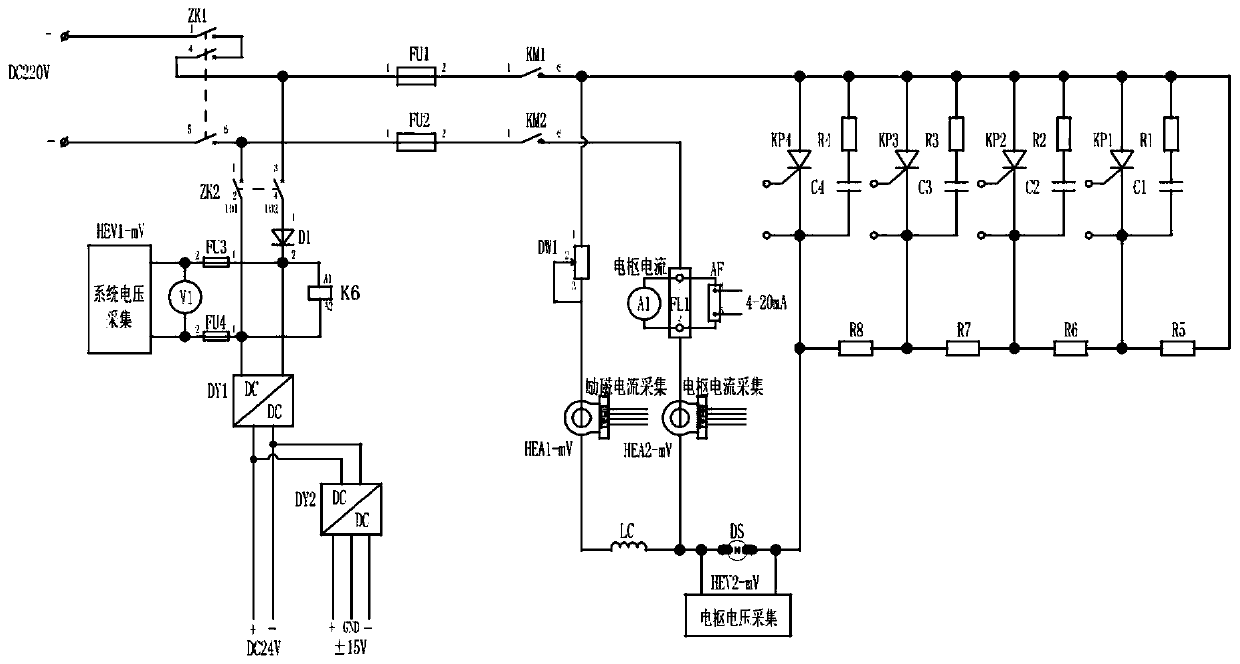

[0018] According to an embodiment of the present invention, an embodiment of a starting control circuit for a DC oil pump motor is provided, figure 1 It is a circuit diagram of the starting control circuit of the DC oil pump motor according to the embodiment of the present invention, such as figure 1 As shown, the circuit includes:

[0019] One or more stages of resistor access circuit 10, wherein each stage of resistor access circuit includes: a switch element and a resistor, wherein the input end of the switch element is connected to the positive pole of the power supply, and the output end of the switch element is connected to the first end of the resistor Connected, and connected to the second end of the resistance in the primary resistance access circuit.

[0020] Specifically, the above-mentioned one-stage or multi-stage resistance access circuit is set in the armature circuit of the motor. figure 1 shows a multi-level resistor circuit, combined with figure 1 As shown...

Embodiment 2

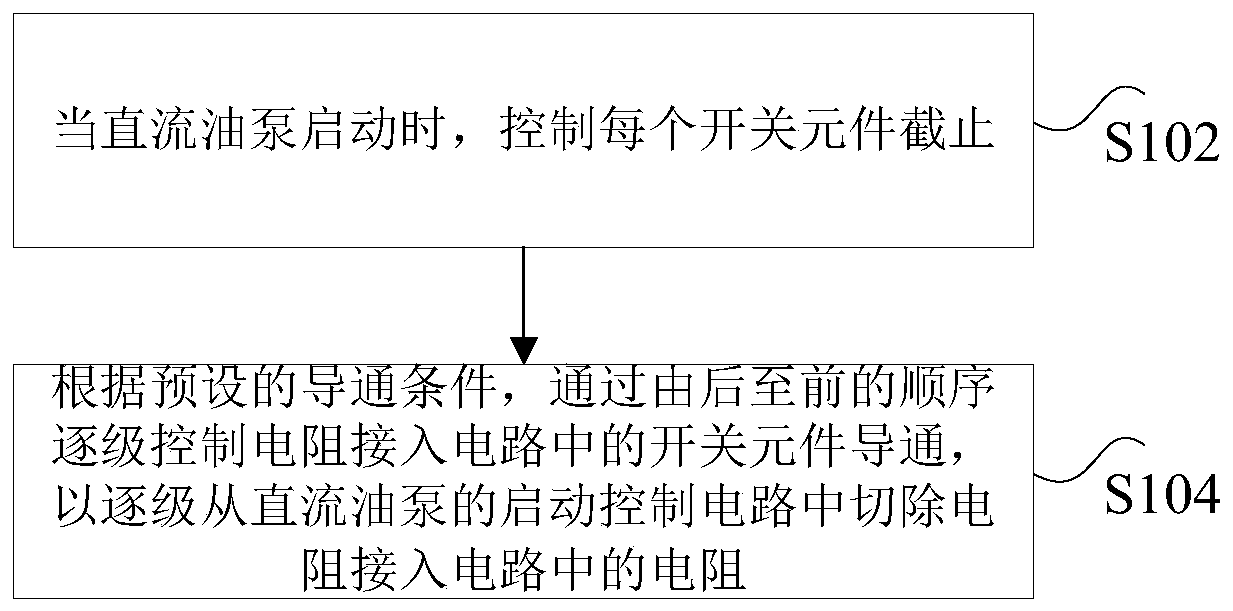

[0059] According to an embodiment of the present invention, an embodiment of a control method for a start-up control circuit of a DC oil pump motor is provided. It should be noted that the steps shown in the flow chart of the accompanying drawings can be implemented in a computer such as a set of computer-executable instructions system, and, although a logical order is shown in the flowcharts, in some cases the steps shown or described may be performed in an order different from that shown or described herein.

[0060] image 3 It is a flow chart of the control method of the start-up control circuit of the DC oil pump motor according to the embodiment of the present invention, the start-up control circuit of the DC oil pump motor includes the start-up control circuit of the DC oil pump motor in Embodiment 1, such as image 3 As shown, the method includes the following steps:

[0061] Step S102, when the DC oil pump motor is started, each switching element is controlled to be ...

Embodiment 3

[0091] According to an embodiment of the present invention, a storage medium is provided, and the storage medium includes a stored program, wherein, when the program is running, the device where the storage medium is located is controlled to execute the control method for the start-up control circuit of the DC oil pump motor in Embodiment 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com