A kind of battery automatic pasting glue method

A technology for sticking glue and batteries, applied in primary batteries, equipment for manufacturing primary batteries, manufacturing of secondary batteries, etc., can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the objects, technical solutions and advantages of the present invention, the present invention will be described in detail below with reference to the accompanying drawings and examples. It will be appreciated that the specific embodiments described herein are intended to explain the invention and is not intended to limit the invention.

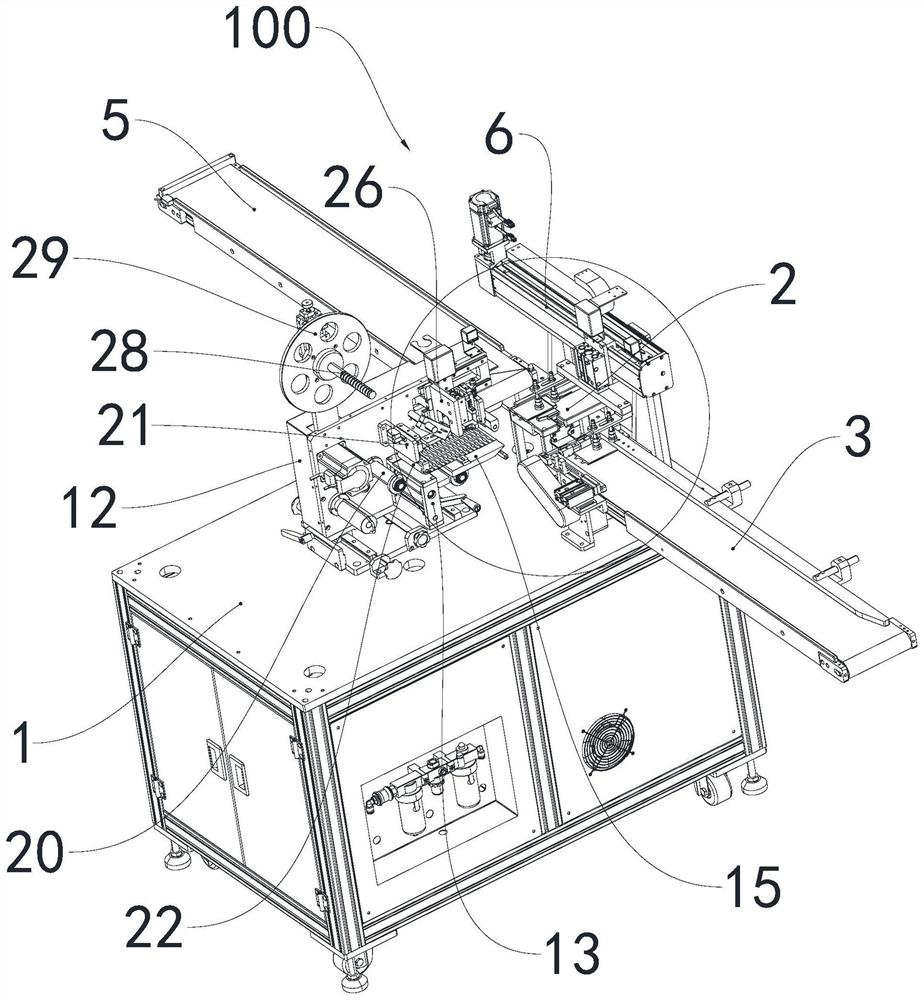

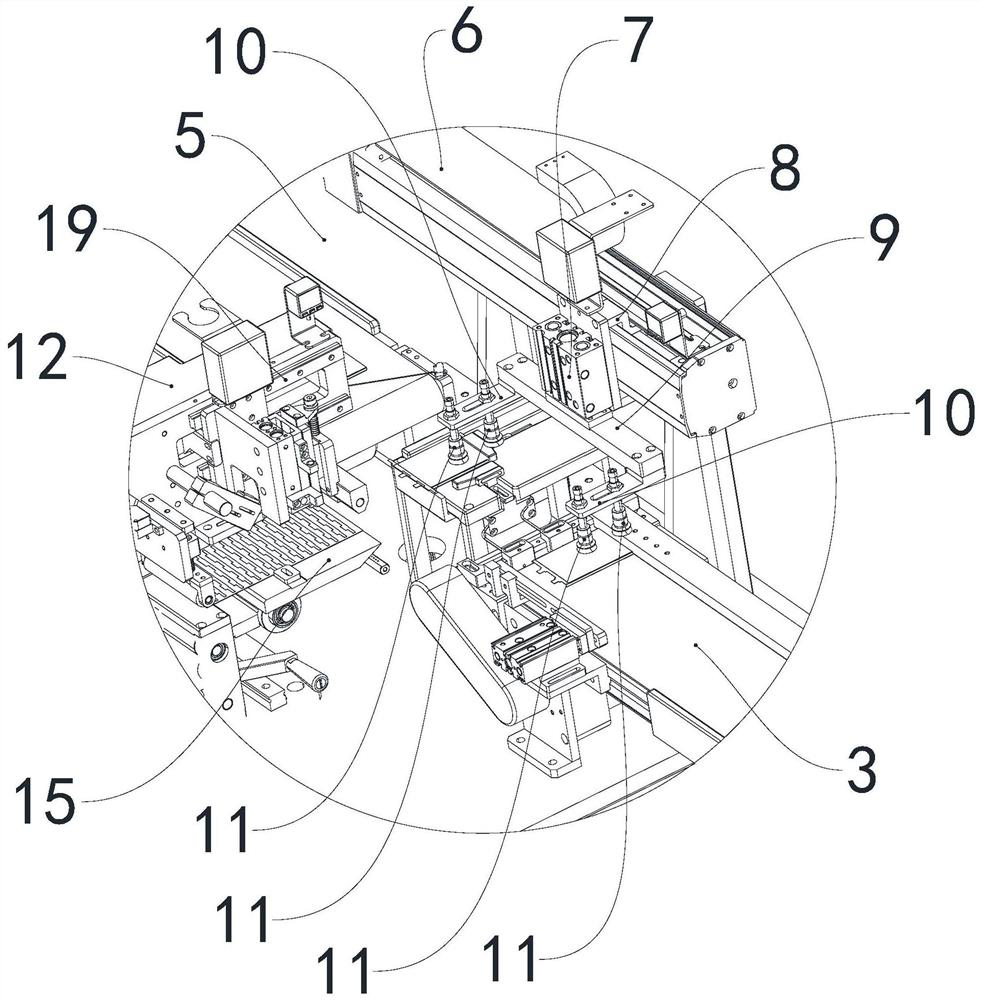

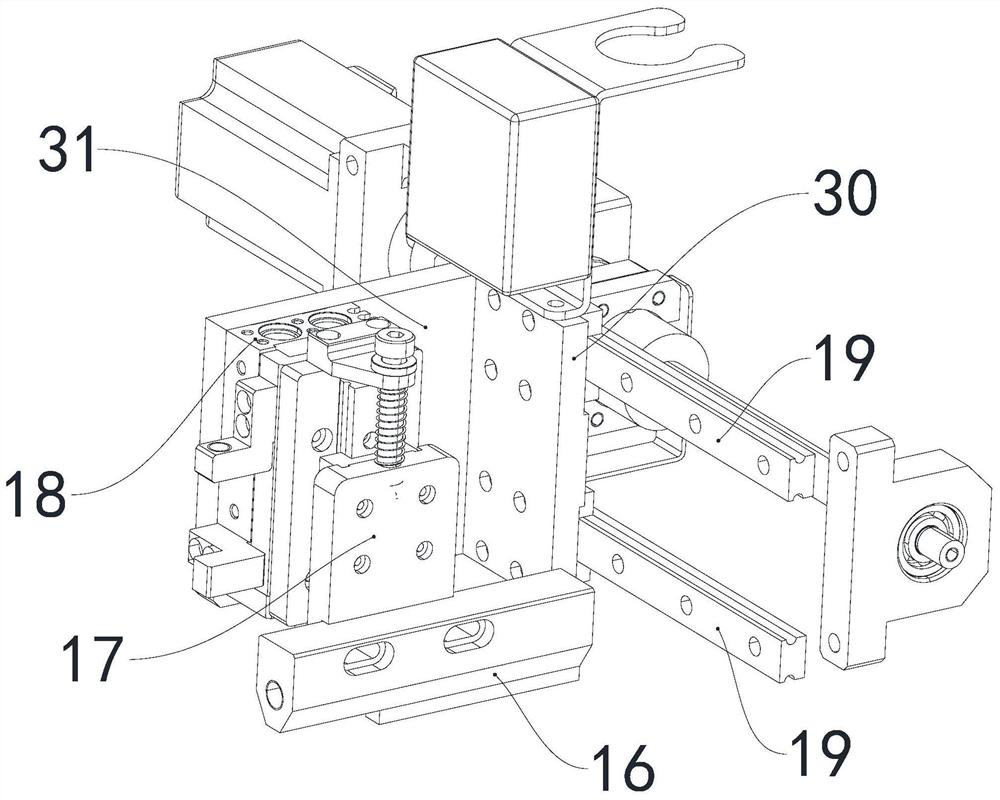

[0021] See figure 1 and figure 2 , The battery of the present embodiment automatically topping device 100 may be applied to battery automatically topping, topping automatic battery apparatus 100 comprises a base station 1, the carrying platform 2, the tape 3 and the lower strip, carrying platform 2, the tape 3 and the strip are mounted on the base station 1, station 2 is located on the carrier strip 3 and the lower strip 5 between the battery apparatus 100 automatically topping further comprises a reclaimer rail 6, 7 take the feed cylinder, the slide member 8, a cross both ends of the vertical frame 10 and the frame 9 sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com