Automatic carton sealing machine

A sealing machine and automatic technology, which is applied in the directions of packaging sealing/fastening, transportation packaging, packaging, etc., can solve the problems that affect the sealing efficiency and time-consuming fixing methods, and achieve the effect of improving the sealing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following is attached Figure 1-6 The application is described in further detail.

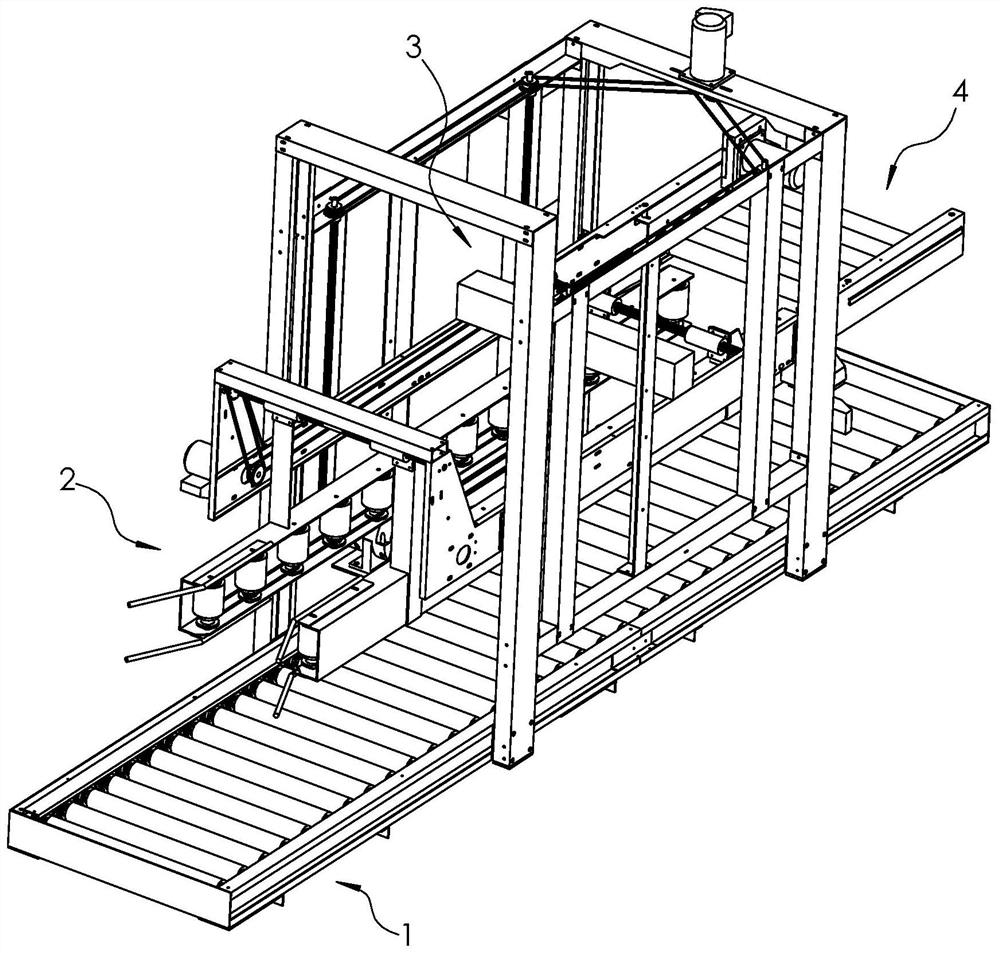

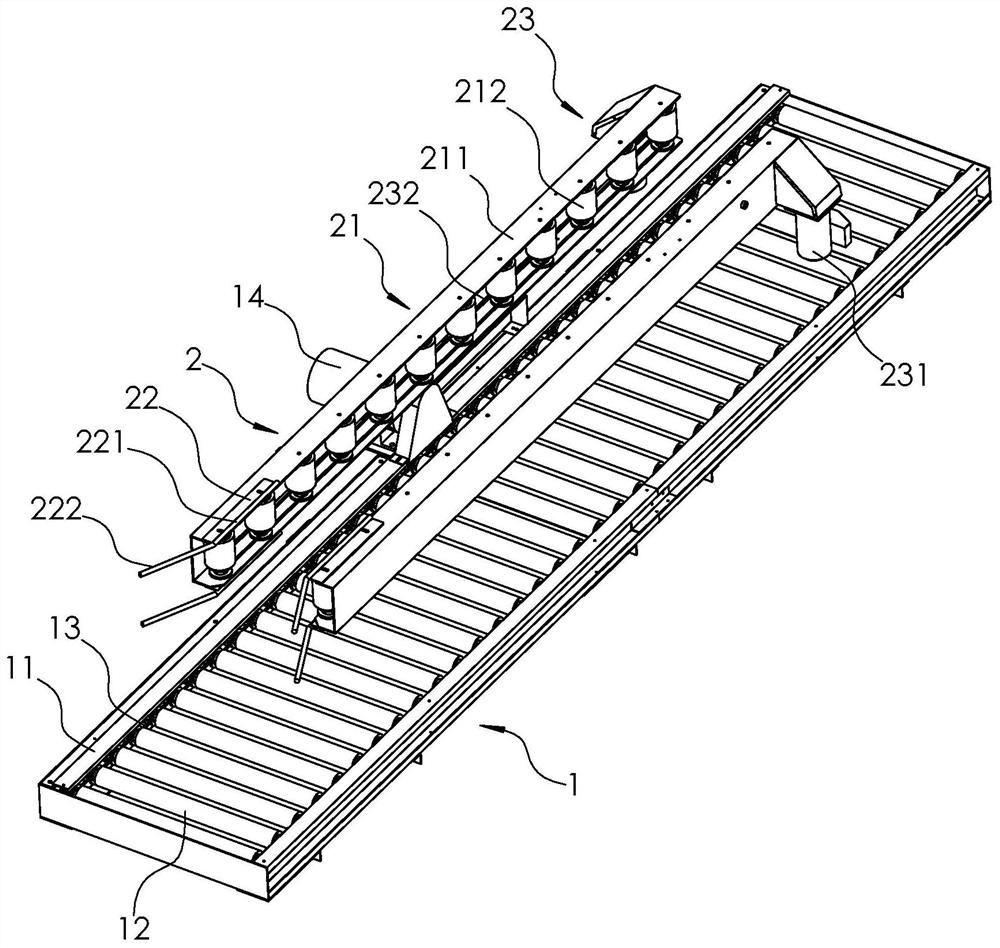

[0040] The embodiment of the present application discloses an automatic box sealing machine. Such as figure 1 As shown, an automatic box sealing machine includes a conveying mechanism 1 for conveying cartons, a material guide mechanism 2, a glue applying mechanism 3 and a pressing mechanism 4 arranged in sequence along the moving direction of the carton; the conveying mechanism 1 is used for conveying the cartons , the material guide mechanism 2 is used to adjust the position of the carton and make the two opposite flanges of the carton fit together, the gluing mechanism 3 is used to bond the pasted two flanges together, and the pressing mechanism 4 is used to Press down the two flanges after gluing, so that the flanges are not easy to warp.

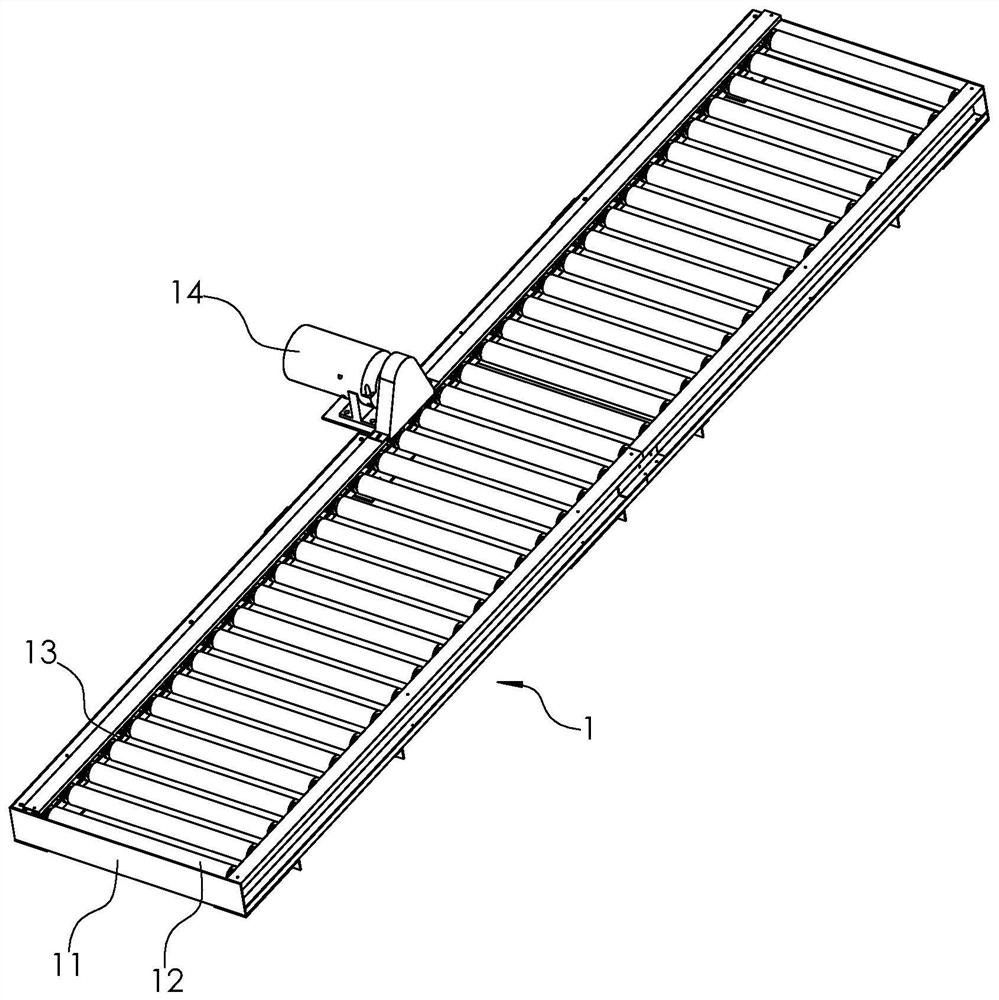

[0041] Such as figure 2As shown, the conveying mechanism 1 includes a base 11, and the base 11 is rotatably connected with a number of co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com