Coating device and coating method for optical cement

A gluing device and optical glue technology, applied to the surface coating liquid device, coating, input/output process of data processing, etc., can solve the problems of increased production cost, waste, low product yield, etc., to achieve The effect of improving work efficiency, reducing production costs and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with the examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limiting the claims of the present invention.

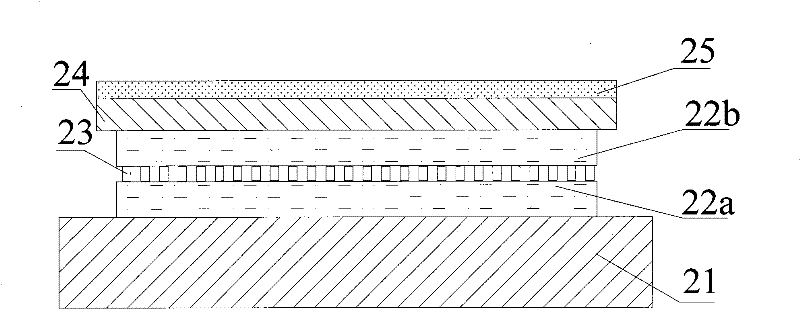

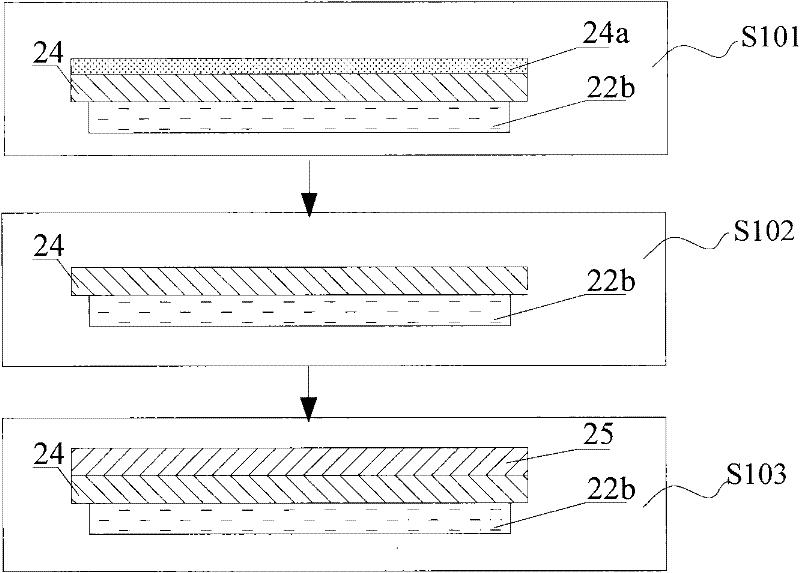

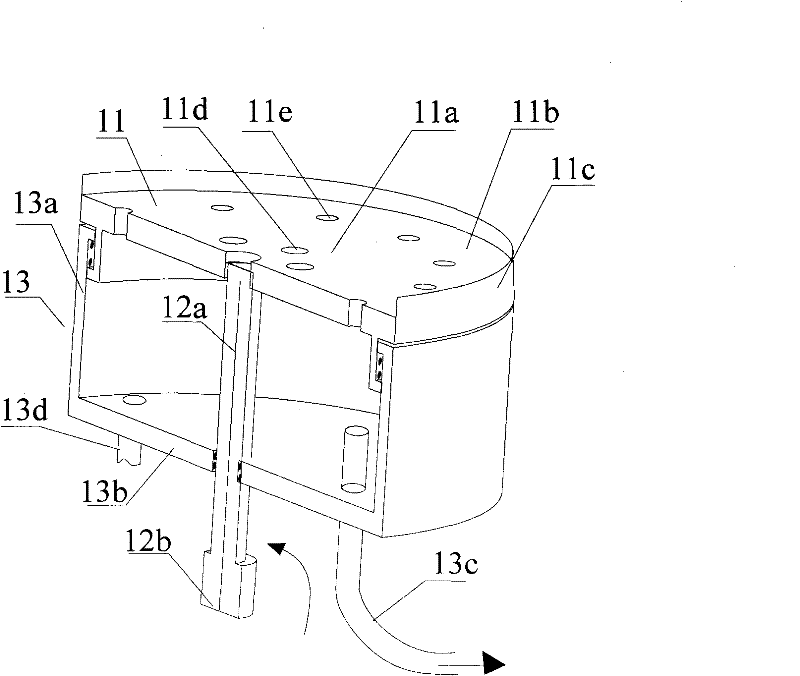

[0038] See image 3 , is a schematic cross-sectional view of a bearing of a specific embodiment of the optical glue coating device provided by the present invention. Such as image 3 As shown, the gluing device includes a circular tray 11 carrying an ITO conductive layer, and the tray 11 includes a circular bearing portion 11a bearing an ITO conductive layer and an edge portion 11b connected to the outer periphery of the circular bearing portion 11a, and the circular bearing portion 11a and the edge portion 11b can be integrally formed, and there is an upright side wall 11c on the outer periphery of the edge portion, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com