Pressure control method of rolling and pressing equipment based on disturbance observer

A disturbance observer and pressure control technology, applied in mechanical pressure/force control, controllers with specific characteristics, adaptive control, etc. The effect of small influence and ensuring precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and implementation examples. It should be understood that the specific implementation examples described here are only used to explain the present invention, not to limit the present invention.

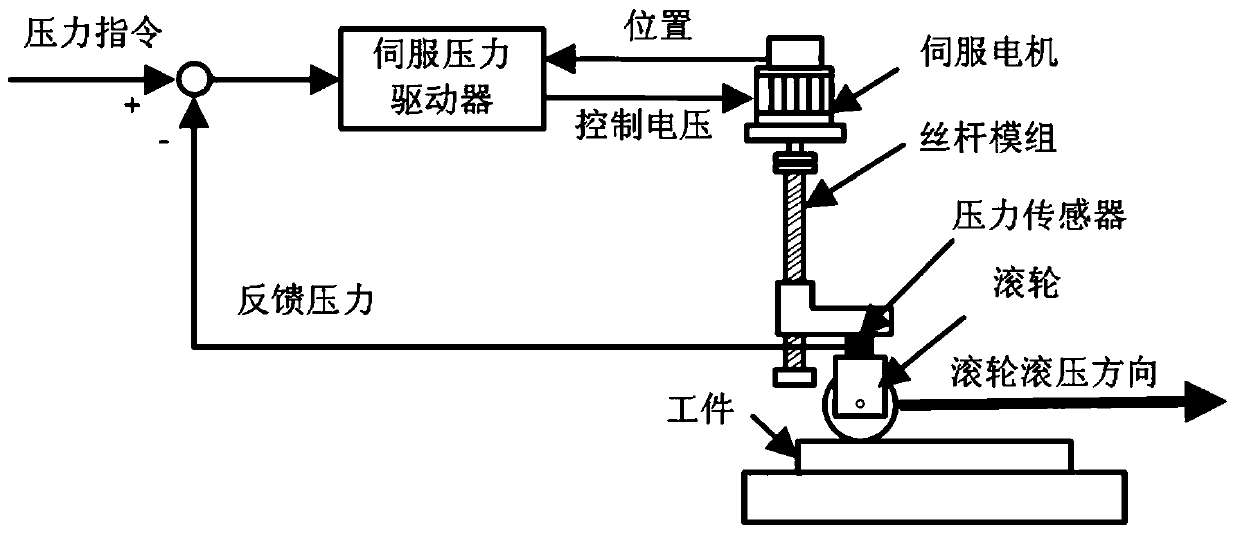

[0051] Such as figure 1 Shown is the schematic diagram of the pressure system of the servo rolling equipment. The servo motor drives the screw to rotate, and drives the rolling head to press down in a direction perpendicular to the plane of the workpiece, thereby exerting pressure on the workpiece. Another servo motor drives the rolling head Roll to achieve a rolling fit. The pressure on the workpiece is fed back to the servo driver through the force sensor, and the motor control command is obtained through the pressure closed-loop controller integrated in the servo driver,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com