Low zero drift PID sensor ionization chamber

A zero-point drift and sensor technology, which is applied in the direction of instruments, circuits, discharge tubes, etc., can solve the serious problems of zero-point drift and achieve the effects of avoiding zero-point drift, improving the performance of the whole machine, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

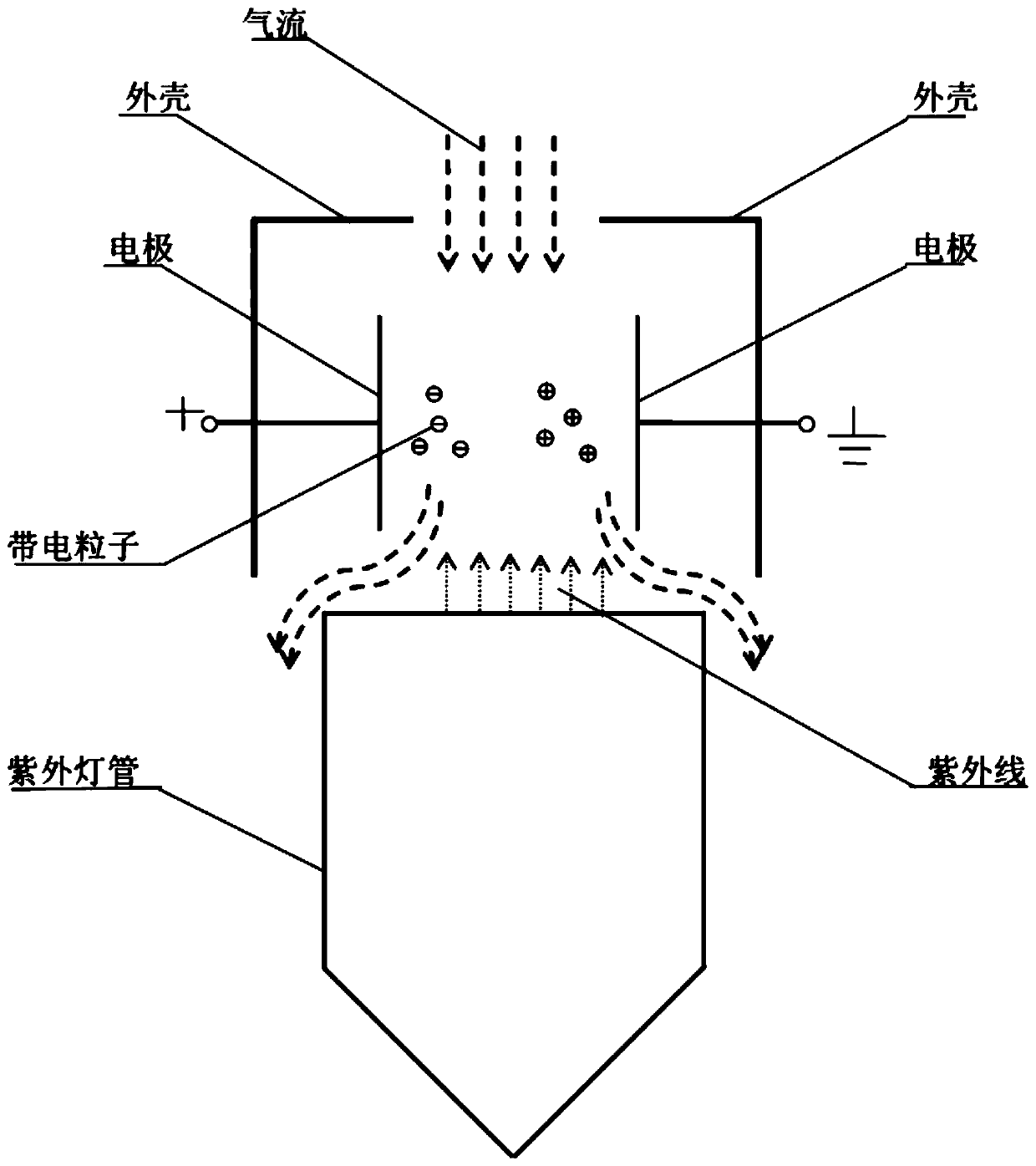

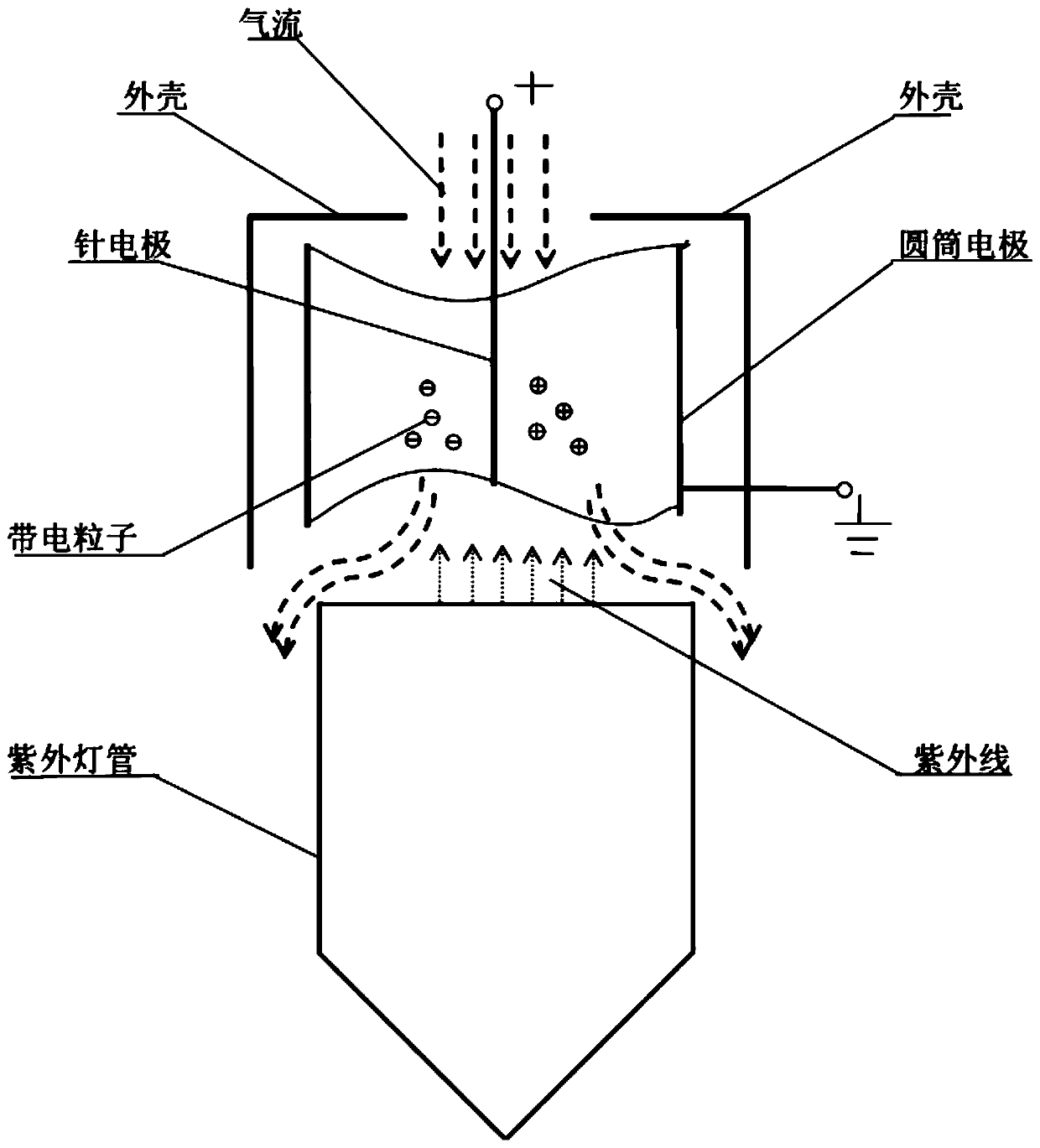

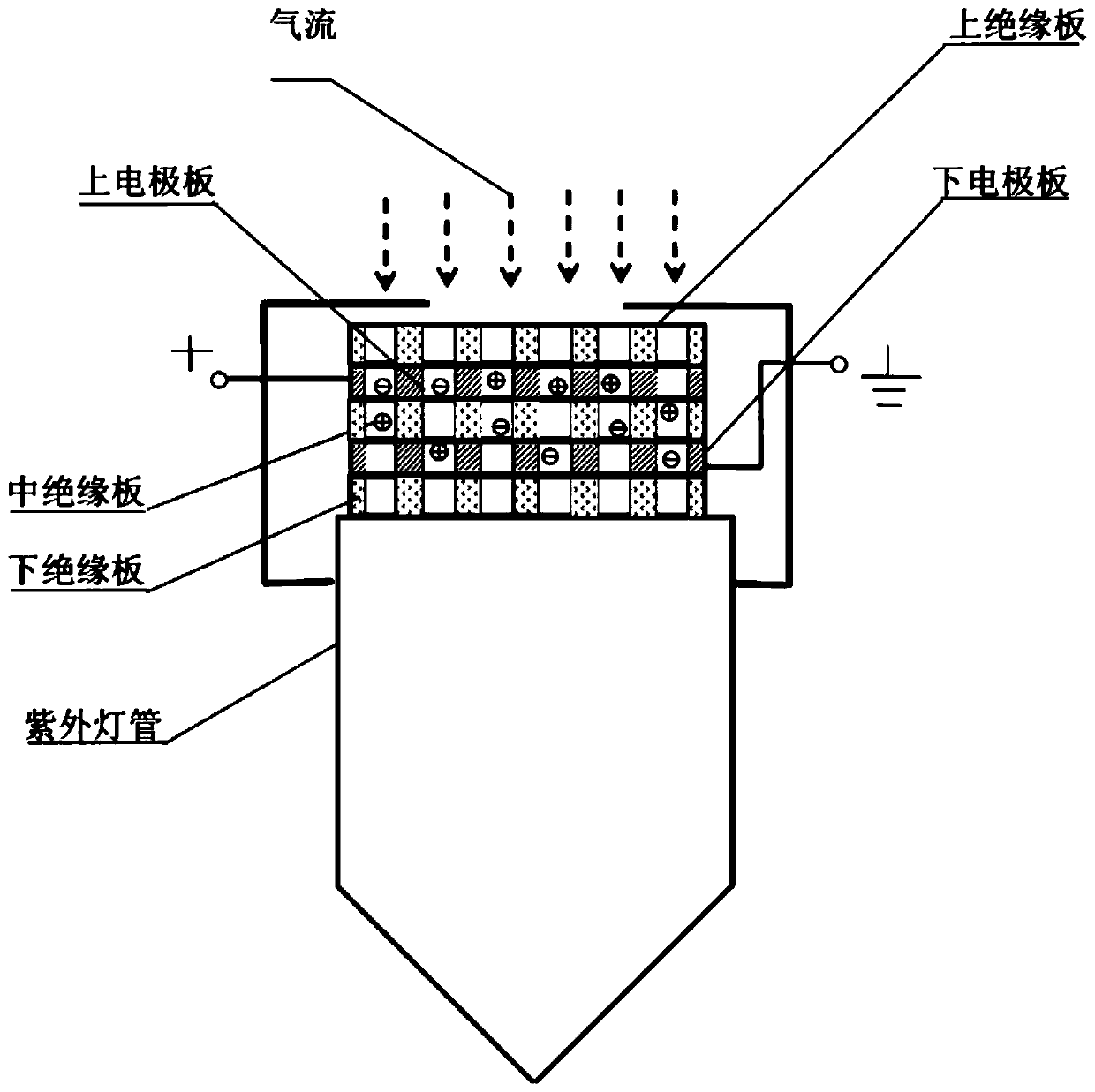

[0034] A low zero drift PID sensor ionization chamber provided in this embodiment has a structure such as Figure 4As shown, it includes a casing 2, an ultraviolet lamp 6, and an electrode assembly. The electrode assembly is arranged in the casing 2. The casing 2 has an airflow inlet 10 and an airflow outlet 11. The light irradiation direction of the ultraviolet lamp 6 is coaxial and opposite to the airflow direction, and is opposite to the direction of the airflow. The direction of the electric field formed by the electrode assembly is coaxial.

[0035] The electrode assembly includes an upper electrode plate 3, an upper light-shielding plate 4, a lower electrode plate 8 and a lower light-shielding plate 5. The upper electrode plate 3 and the lower electrode plate 8 are respectively connected to the positive and negative poles of the DC high-voltage power supply to form an electrostatic field and collect the target gas 1 The signal produced after ionization. The lower light ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com