Optical-electro-mechanical vibration angular speed sensor

An angular rate sensor, optical electromechanical technology, applied in the direction of instruments, devices using optical methods, measuring devices, etc., can solve the problems of low sensitivity, easy to be affected by temperature, etc., achieve small volume, high zero stability, reduce The effect of thermal noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The work of the present invention will be described in detail below in conjunction with the accompanying drawings.

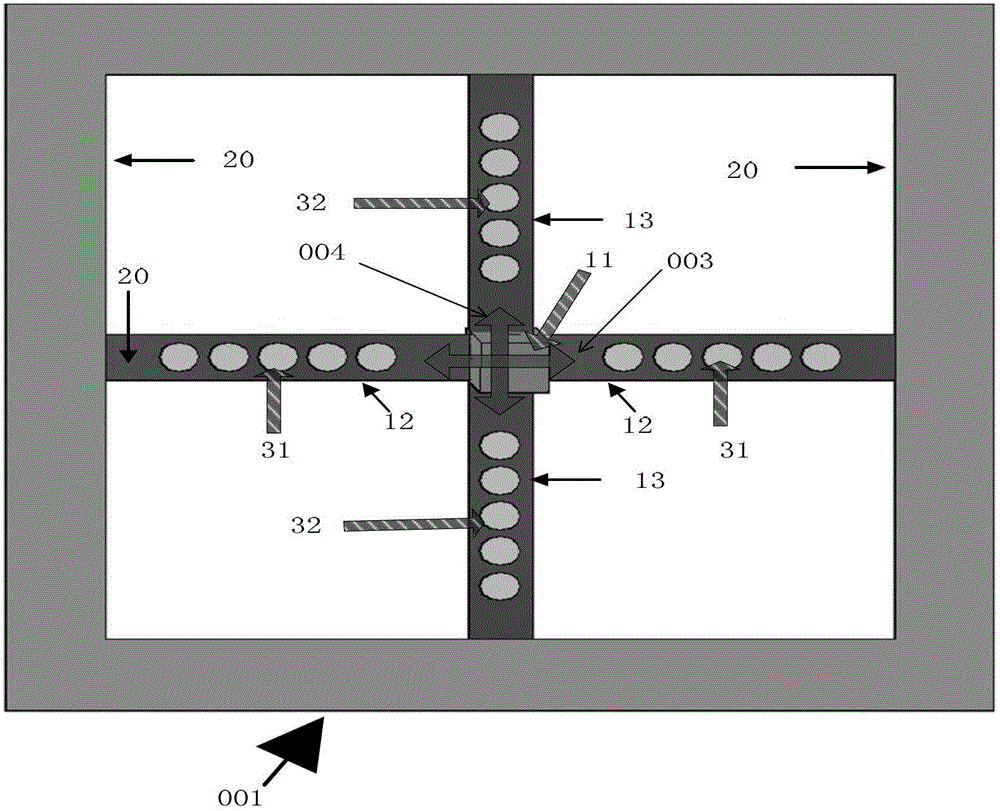

[0016] Such as figure 1 Shown is the top view of the opto-electromechanical vibration angular rate sensor of the present invention. The opto-electromechanical vibration angular rate sensor includes: a vibration system (10) composed of a vibrating mass (11) through a set of driving arms (12) and sensitive arms (13), the vibration system is connected to an external support structure through the driving arms and sensitive arms (20) Connecting, the driving arm vibrates under the action of the all-optical drive system (31), driving the vibrating mass to swing near the equilibrium position, thereby generating linear momentum; in the direction of the input axis (002) of the angular rate sensor Input the angular velocity, when the angular rate sensor is on figure 2 When there is an input angular velocity in the direction of the middle input axis (002), the vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com