Constant temperature combustable gas concentration detector

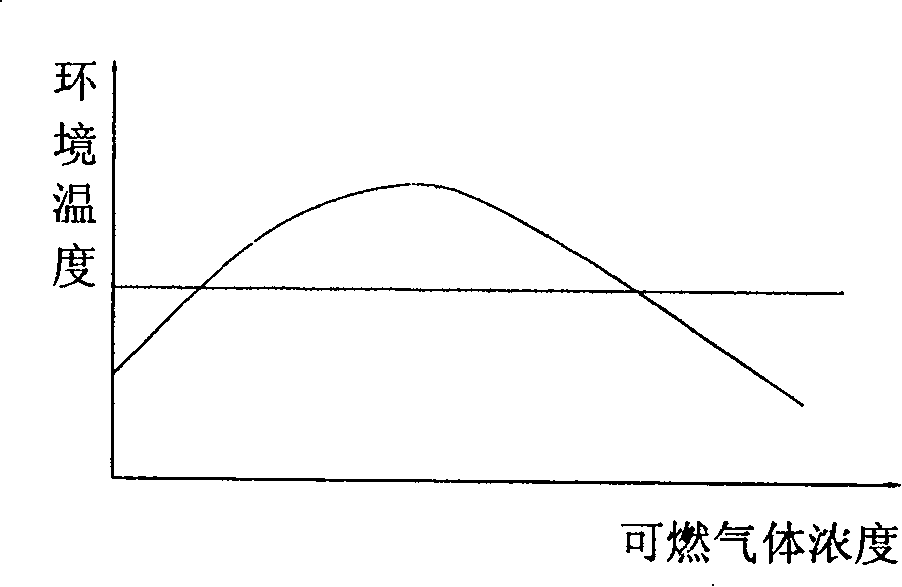

A gas concentration detection, constant temperature technology, applied in the direction of material resistance, can solve the problems of unstable carbon deposition structure, damage to sensitive components, small detection range, etc., to achieve good zero point stability, extended detection range, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

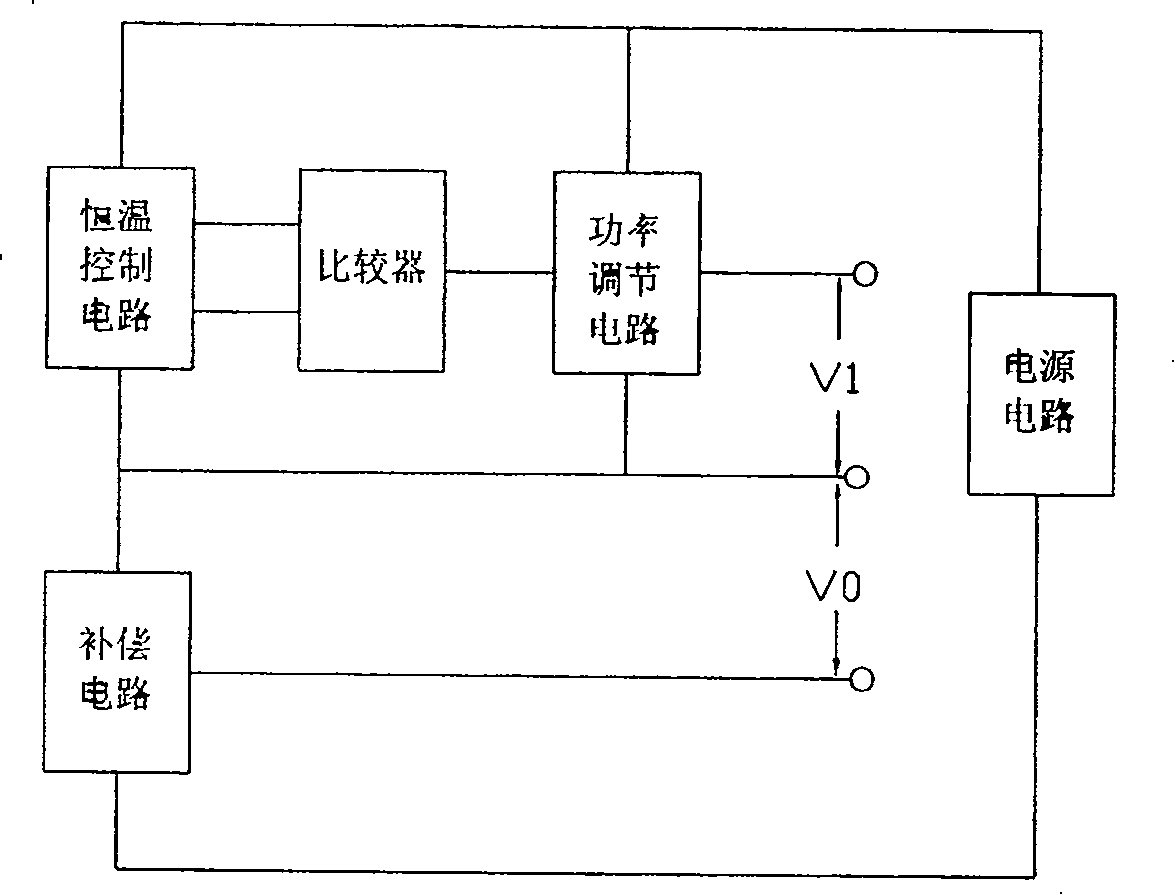

[0018] control figure 2 , the invention is composed of bridge, comparator, power regulator and compensation circuit. The comparator is connected to the bridge and the power regulator to form a constant temperature control loop. The constant temperature control loop and the compensation circuit are connected in series to a constant current power supply circuit. The constant temperature control loop outputs a detection signal V0, and the compensation circuit outputs a compensation signal V1.

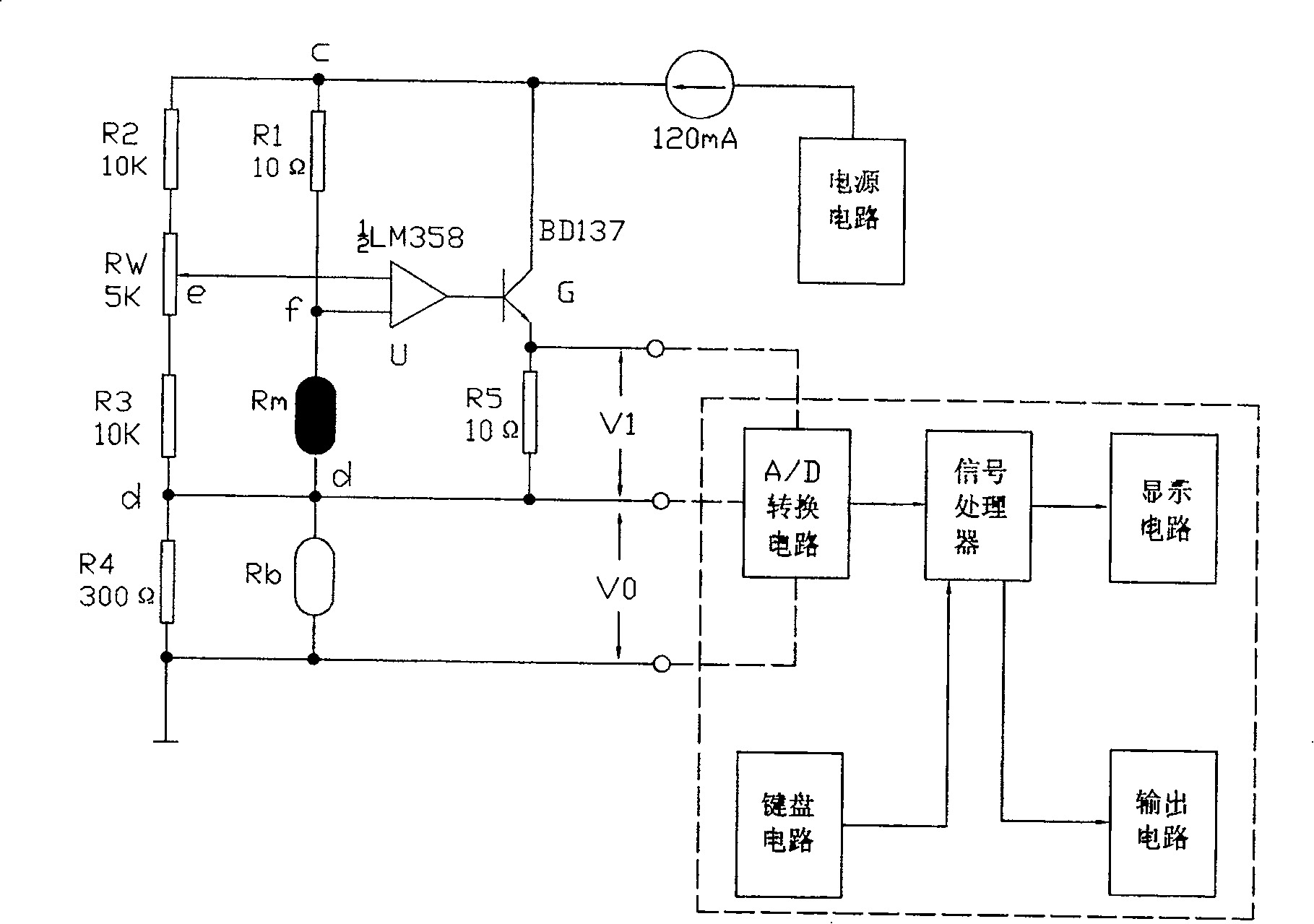

[0019] combine image 3 , The bridge is composed of sensitive element Rm and resistors R1, R2, R3, Rw, Rm is a sensitive element with a catalyst, and the resistance values of R1, R2, R3, Rw are 10Ω, 10K, 10K, 5K respectively. The detection output terminals e and f of the bridge are connected to the input terminal of the comparator U, the output termina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com