Life test method and equipment for automobile cooling system part

A technology for automobile cooling and components, which is applied in the field of life test methods and test equipment for automobile cooling system components, can solve the problems of slow temperature change rate, low test efficiency, small test pressure range, etc., achieve accurate test results, improve Temperature change rate, the effect of increasing the adjustable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] As mentioned in the background art, in the prior art, when testing the life of components of the automobile cooling system, the test pressure range is small, the temperature change rate is slow, and the test efficiency is low.

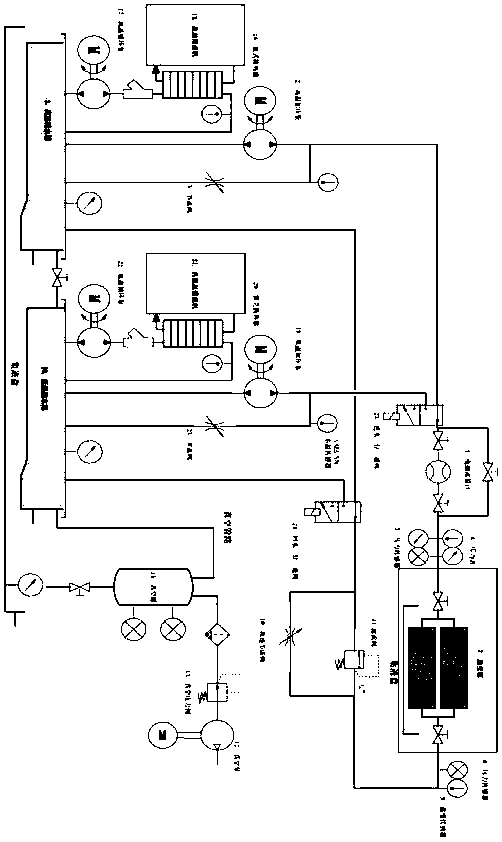

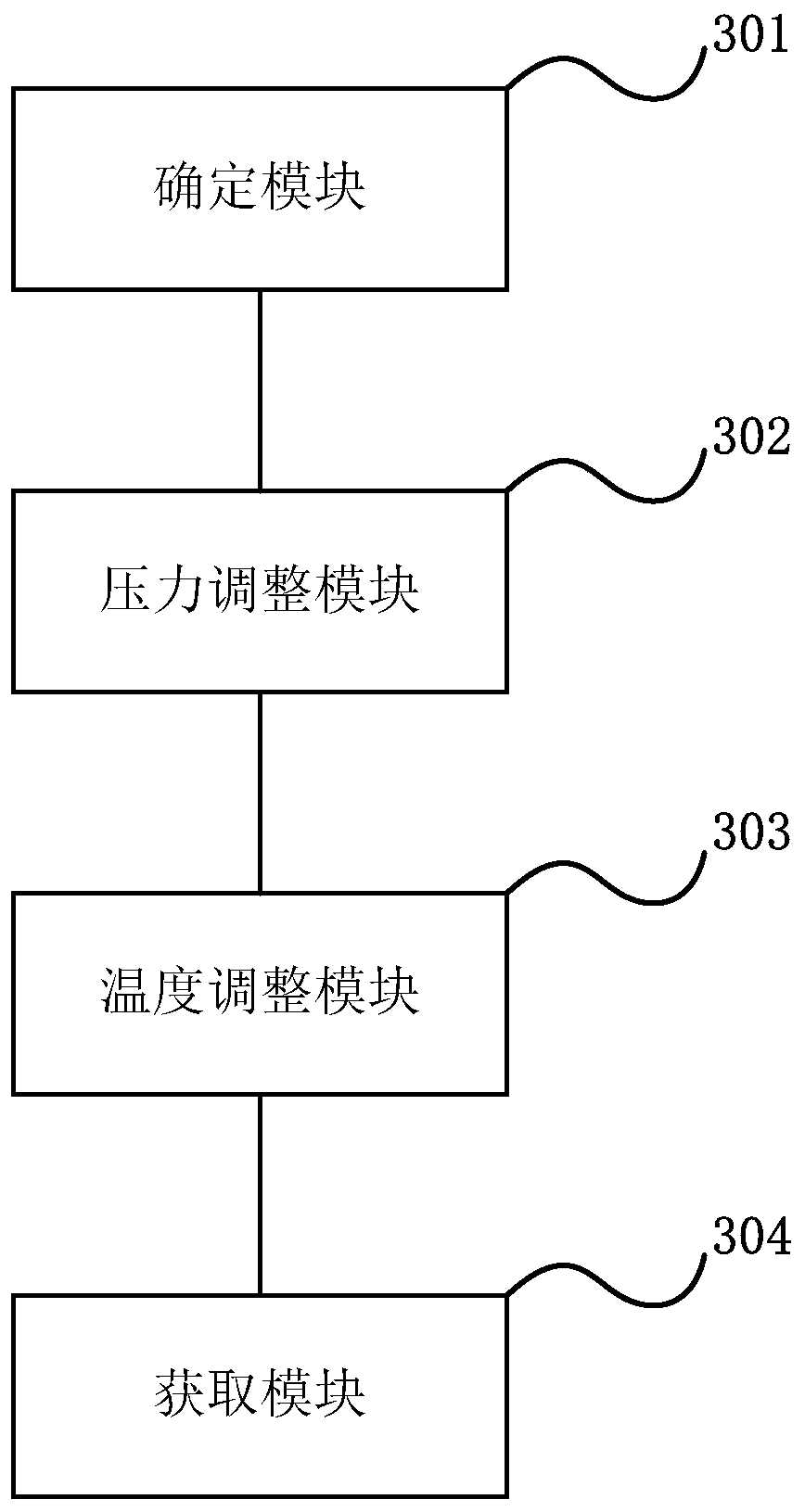

[0051] In order to solve the above problems, the embodiment of the present application proposes a life test method for the components of the automobile cooling system. The pressure is adjusted through the vacuum pump and the high-speed throttle valve, and the temperature is adjusted through the high-temperature water storage tank and the low-temperature water storage tank to increase the pressure. The adjustable range effectively improves the temperature change rate and obtains more accurate test results.

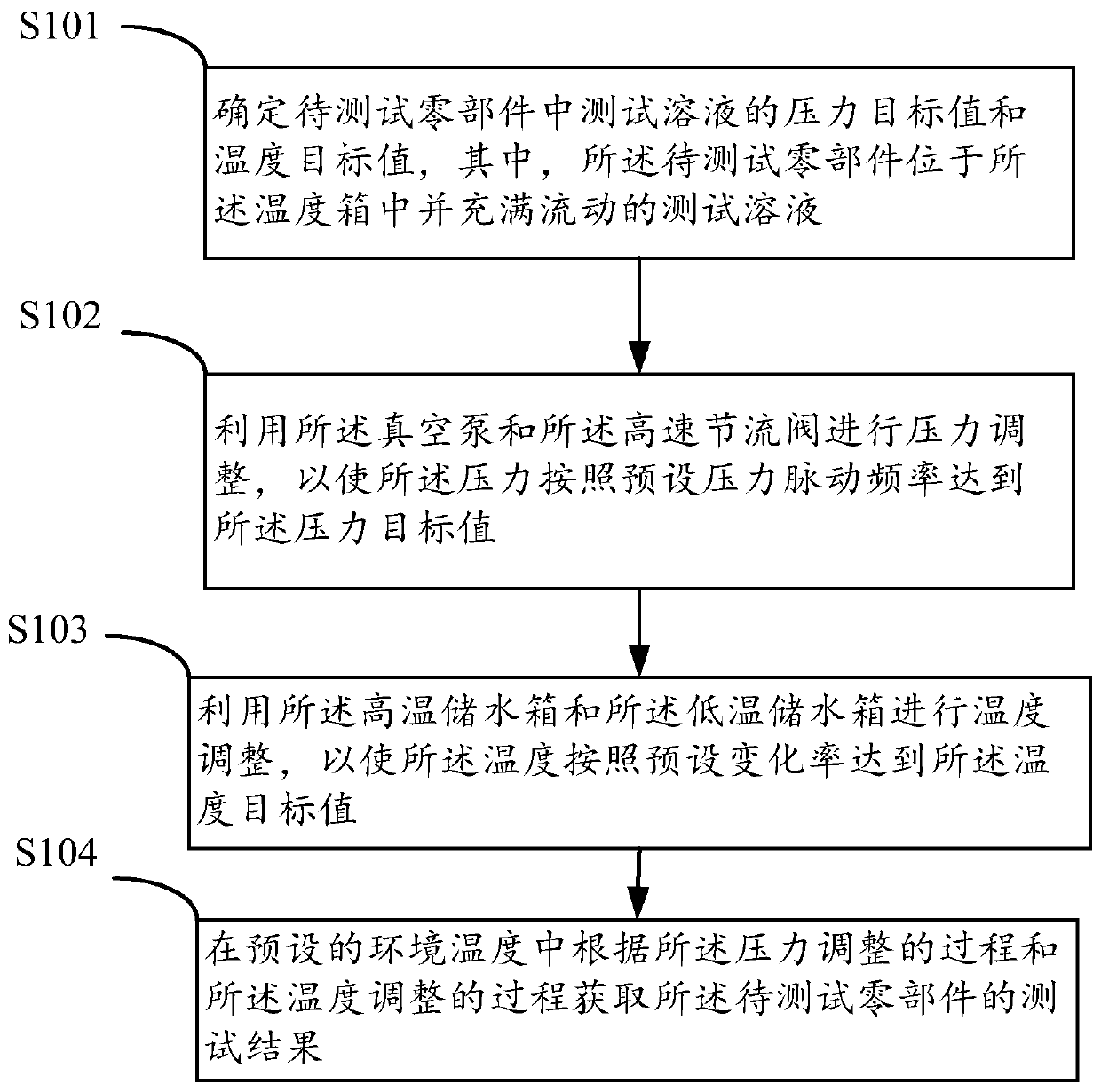

[0052] Such as figure 1 Shown is a schematic flow chart of a life testing method for automotive cooling system components proposed in an embodiment of the present invention, which is applied to testing equipment including a temperature box, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com