A smelting method for producing IF steel with low oxygen level in the whole process

A smelting method and a whole-process technology, applied in the field of iron and steel smelting, can solve the problems of unavoidable final slag oxidation of the converter, increase the labor load of on-site operators, and unfavorable on-site standardized operations, so as to improve the cleanliness level of molten steel and enhance decarburization effect, the effect of significant economic benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

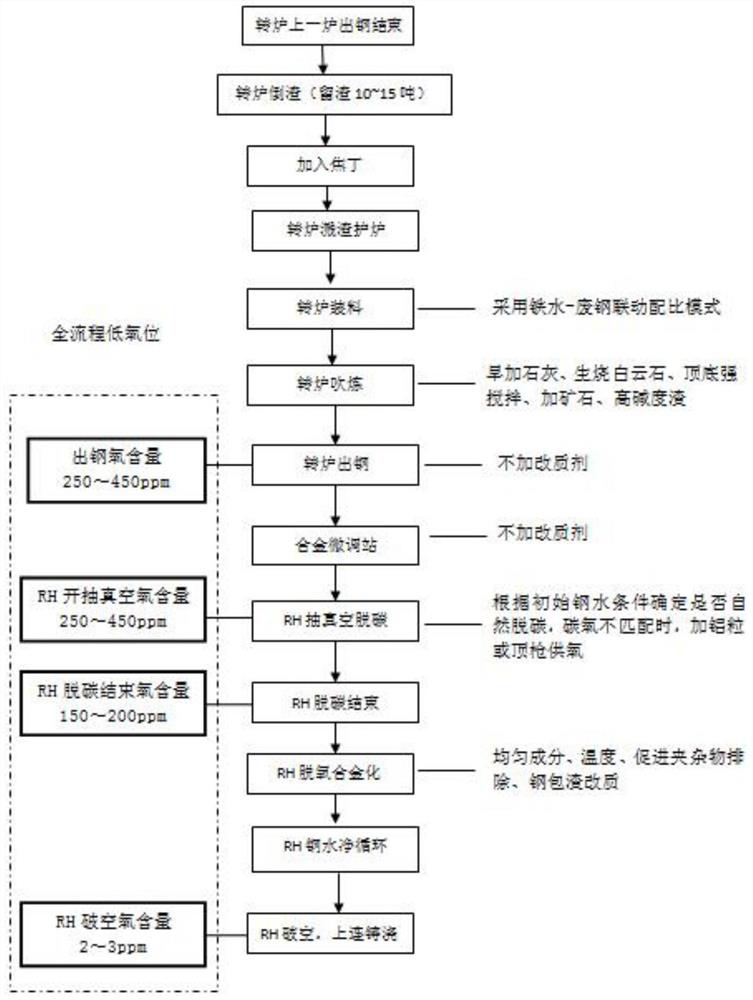

[0027] from figure 1 It can be seen that the smelting method for producing IF steel in a whole process low-oxygen position of the present embodiment, the steps are:

[0028] Step 1: After the smelting of the converter steel, the slag is poured, and 10-15 tons of slag is left in the converter, and 50-100 kg of coke powder is added to remove the oxygen in the slag, and then the slag splashing operation is carried out to protect the furnace;

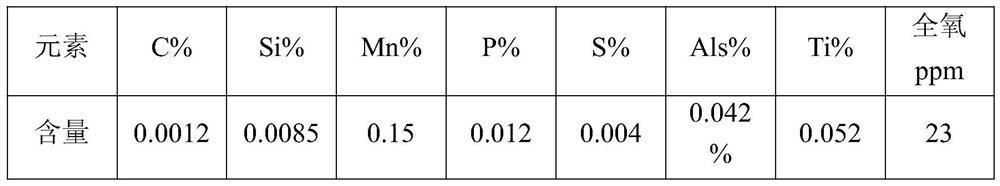

[0029] The chemical composition requirements of IF steel are: C≤0.0050%, Si≤0.01%, Mn: 0.08~0.25%, P≤0.015%, S≤0.008%, Als: 0.030~0.050%, Ti: 0.030~0.070%;

[0030] The slag composition range of converter slag is: TFe: 12-25%, CaO: 40-60%, SiO 2 : 10~18%, MnO: 2~3%, MgO: 3~6%;

[0031] Composition of coke powder is C≤94%, H2O≤0.020%, S≤0.022%, volatile + ash≤5%, particle size 5-15mm;

[0032] Step 2: Converter charging; the molten iron-scrap linkage ratio mode is adopted, and the amount of molten iron and scrap added is based on the prin...

Embodiment 2

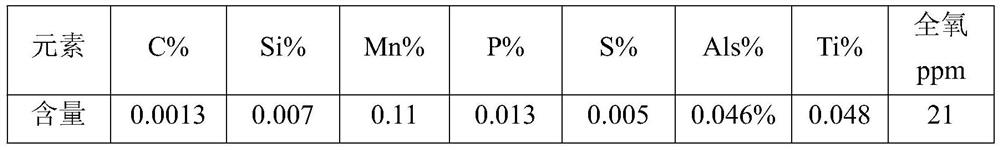

[0064] A kind of smelting method of producing IF steel in the low oxygen position of the whole process of the present embodiment, its steps are:

[0065] Step 1: After the smelting of the last furnace of steel in the converter, the slag is dumped, leaving 13 tons of slag in the converter, adding 75 kg of coke powder to remove the oxygen in the slag, and then performing slag splashing to protect the furnace;

[0066] Step 2: Converter charging: adopt the molten iron-scrap linkage ratio mode, add 298t of molten iron and 33t of scrap steel, of which molten iron Si: 0.28%;

[0067] Step 3: Converter main blowing: Calculated according to “lime addition = 2.14×W[Si]×R×1000 / A”, the total lime addition is 27.1kg / t steel, where W[Si]: 0.28 %, R: 4, W(CaO): 90%, W(SiO 2): 0.35%: tapping amount: 297t, you need to add 8.0t of lime: 4 minutes before blowing: add lime to the converter in 3 batches, keep the lance position at 2.7m, and the oxygen flow rate of the top lance is 63000m 3 / h, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com