A kind of water-based silicate composite heat-insulating flame-retardant coating and preparation method thereof

A flame retardant coating and silicate technology, applied in the coating field, can solve the problems of large pollution, single function and poor adhesion of architectural coatings, and achieve the effects of low cost, convenient construction and good weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

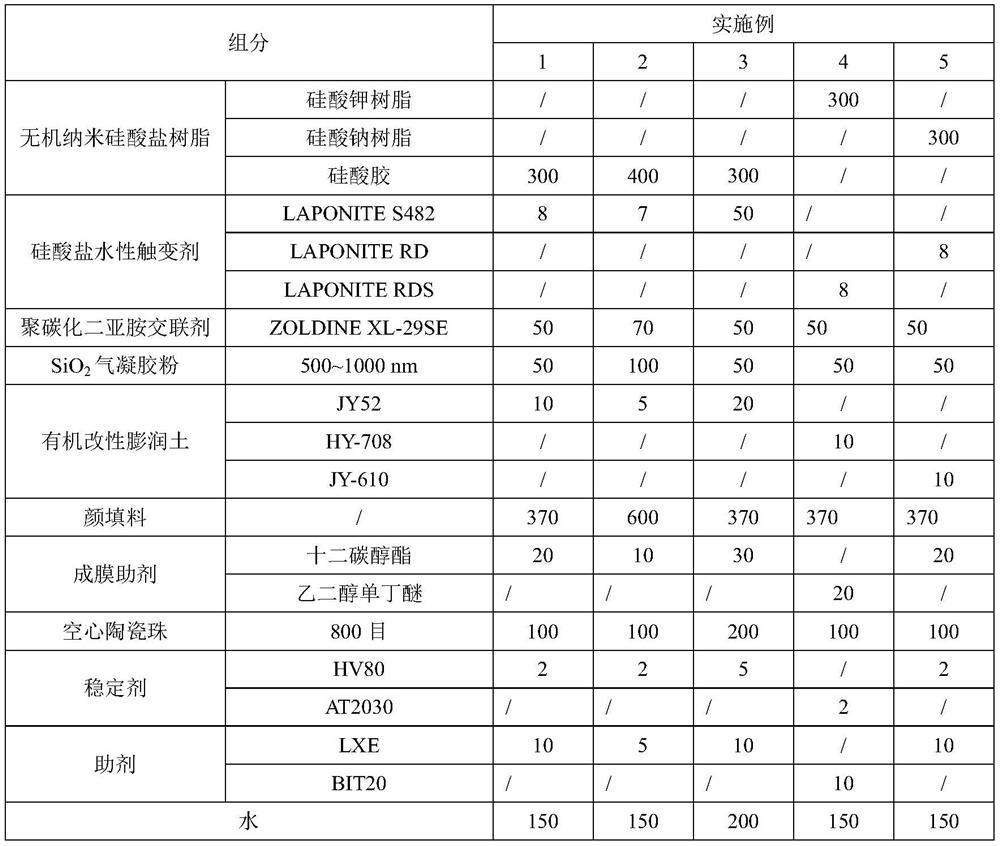

[0055] This example provides a water-based silicate composite heat-insulating and flame-retardant coating, the formula of which is shown in Table 1 below. The water-based silicate composite heat-insulating and flame-retardant coating is prepared by the following method: put each component into a dispersing kettle and disperse for 15-20 minutes at a speed of 1000-1200 r / min, and finally form a colored paste, which is qualified after inspection and ready for use.

[0056] The formula (unit: g) of table 1 embodiment 1~5

[0057]

[0058] The auxiliary agent is composed of: defoamer (NXZ): 1g, preservative (LXE): 9g.

[0059] The composition of pigment and filler (370g) is: barium sulfate: 50g, kaolin: 150g, rutile titanium dioxide 100g, natural marble powder 50g, sericite powder 20g.

[0060] The composition of pigment and filler (600g) is: barium sulfate: 80g, kaolin: 240g, rutile titanium dioxide 160g, natural marble powder 80g, sericite powder 40g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com