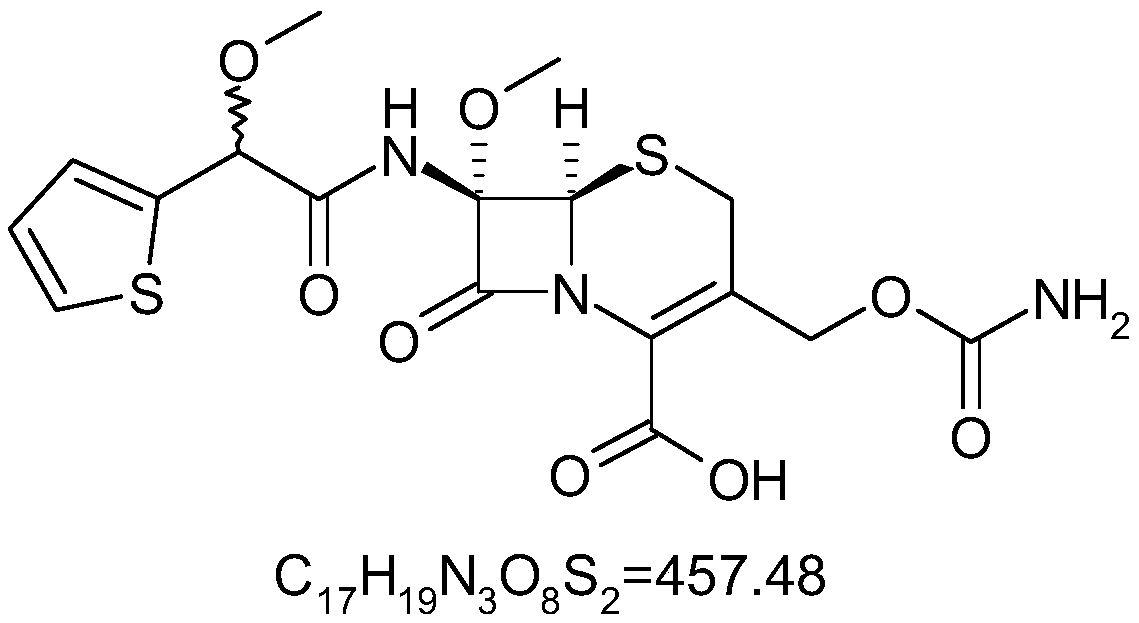

Preparation method of (RS)-methoxy cefoxitin

A methoxycefoxitin and methoxyl technology, applied in the field of impurity analysis in drug synthesis, can solve problems such as affecting drug efficacy, toxic and side effects, and achieve the effects of clinical safety use guarantee, simple steps and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

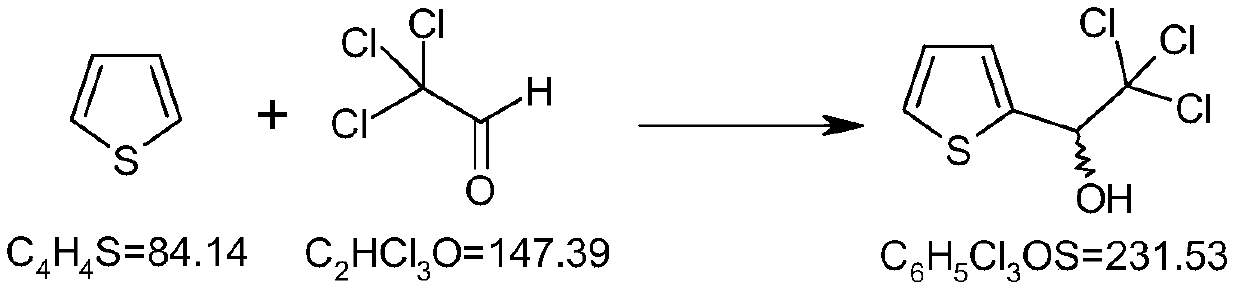

Embodiment 1

[0036] The chemical reaction formula for the preparation of (RS)-α-trichloromethyl-2-thiophenemethanol

[0037]

[0038] Add 84g (1.0mol) of thiophene, 500ml of n-heptane and 147g (1.0mol) of chloral into a 1000ml three-necked flask, stir, heat up to reflux, cool down to room temperature after the reaction, concentrate under reduced pressure to recover the solvent, and depressurize the residue Distillation, collecting 98 ~ 100 ℃, 1.0mmHg fraction, yield about 46g.

Embodiment 2

[0040] Preparation of (RS)-α-trichloromethyl-2-thiophenemethanol

[0041] Add 84g (1.0mol) of thiophene, 500ml of n-heptane and 147g (1.2mol) of chloral into a 1000ml three-necked flask, stir, heat up to reflux, cool down to room temperature after the reaction, concentrate under reduced pressure to recover the solvent, and decompress the residue Distillation, collecting 98 ~ 100 ℃, 1.0mmHg fraction, yield about 52g.

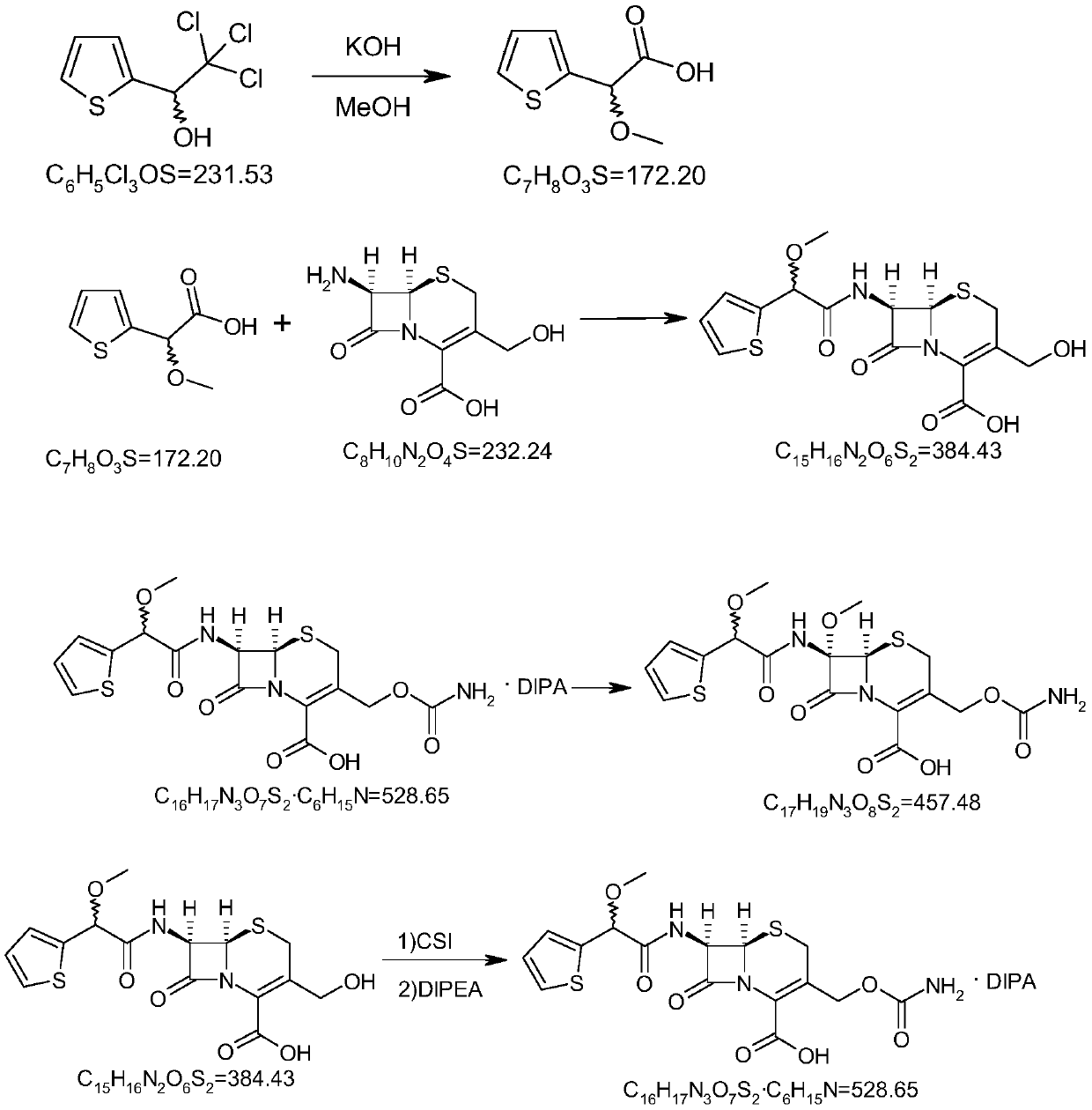

Embodiment 3

[0043] The chemical reaction formula for the preparation of (RS)-α-methoxy-2-thiophene phenylacetic acid

[0044]

[0045]Under nitrogen protection, add 100ml methanol and 11.2g (0.2mol) potassium hydroxide into a 500ml three-necked flask, stir to dissolve, cool to -5~0°C, add 11.6g (0.05mol) (R,S)-α-tri A solution of chloromethyl-2-thiophene methanol in 30ml of methanol, stirred, slowly heated to reflux, cooled to room temperature after the reaction, concentrated under reduced pressure to remove the solvent, added 50ml of methyl tert-butyl ether to the residue, and used under stirring Adjust the pH to 3.0 with 0.1N dilute hydrochloric acid, separate the organic layer, extract the aqueous layer with methyl tert-butyl ether again, combine the organic layers, wash with brine, dry over anhydrous sodium sulfate, filter, and concentrate under reduced pressure to obtain about 6.2 g of product .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com