Micro-vortex flocculation and inclined pipe sedimentation water treatment device based on sludge water reuse, and treatment method thereof

A technology of micro-vortex flocculation and water treatment equipment, which is applied in the direction of sedimentation treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. It can solve the problems of poor coagulation effect of water supply, avoid the deterioration of effluent water quality and improve efficiency , Strengthen the effect of coagulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A micro-vortex flocculation inclined tube sedimentation water treatment device based on sludge water reuse mainly includes three components: micro-vortex enhanced coagulation and inclined tube sedimentation unit, sludge water collection and sedimentation unit, and sludge water reuse unit , see the specific structure figure 1 ;

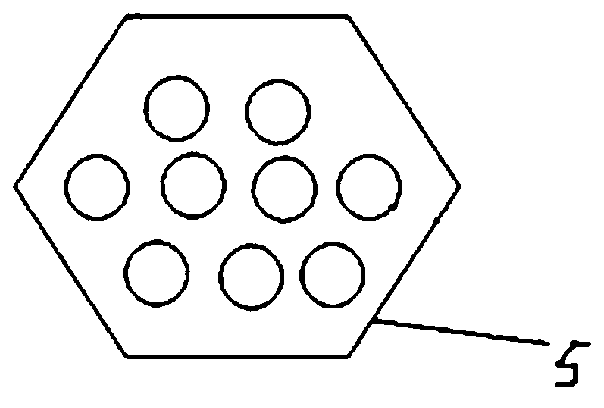

[0036] The micro-vortex enhanced coagulation and inclined tube sedimentation unit is sequentially equipped with water inlet pipe 1, static pipe mixer 2, water distribution bell mouth 3, vortex reaction chamber 4, transition section 6, inclined tube sedimentation tank, water outlet pipe 9; water distribution bell mouth 3 It is arranged below the vortex reaction chamber 4, the vortex reaction chamber 4 is provided with a regular hexagonal vortex reactor 5, the inclined tube sedimentation tank is provided with an inclined tube 8, the middle and lower part of the transition section 6 is provided with a water distribution hole 7, and the transition s...

Embodiment 2

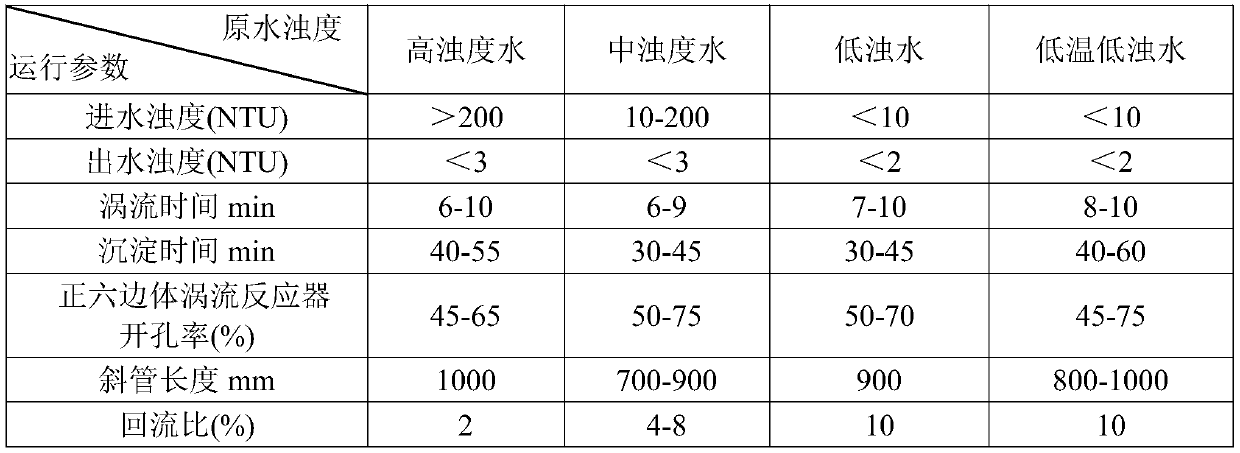

[0041] A micro-vortex flocculation inclined tube sedimentation water treatment method based on sludge water reuse, including the following steps. The specific operating parameters are shown in Table 1:

[0042] 1 Micro vortex flocculation: Raw water is input into static pipeline mixer 2 through water inlet pipe 1, and coagulant is added at the same time, and raw water and coagulant are fully mixed in static pipeline mixer 2 to obtain reaction water 1; after that, the mixed solution passes through The water distribution bell mouth 3 evenly distributes water into the vortex reaction tank 4, and the coagulation reaction is strengthened through the regular hexagonal vortex reactor 5 in the vortex reaction tank 4, and the reaction water 2 and sludge 1 are obtained; after that, the reaction solution 2 is turned into the transition section 6. The sludge 1 sinks into the sludge hopper 10 of the reaction tank set under the vortex reaction tank 4; the regular hexagonal vortex reactor 5 n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com