A process for advanced treatment of artificial sweetener sewage based on UV advanced oxidation

An artificial sweetener and advanced oxidation technology, which is applied in the fields of oxidized water/sewage treatment, natural water treatment, water treatment parameter control, etc. Negative growth of sucralose and other problems to achieve the effect of solving biodegradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

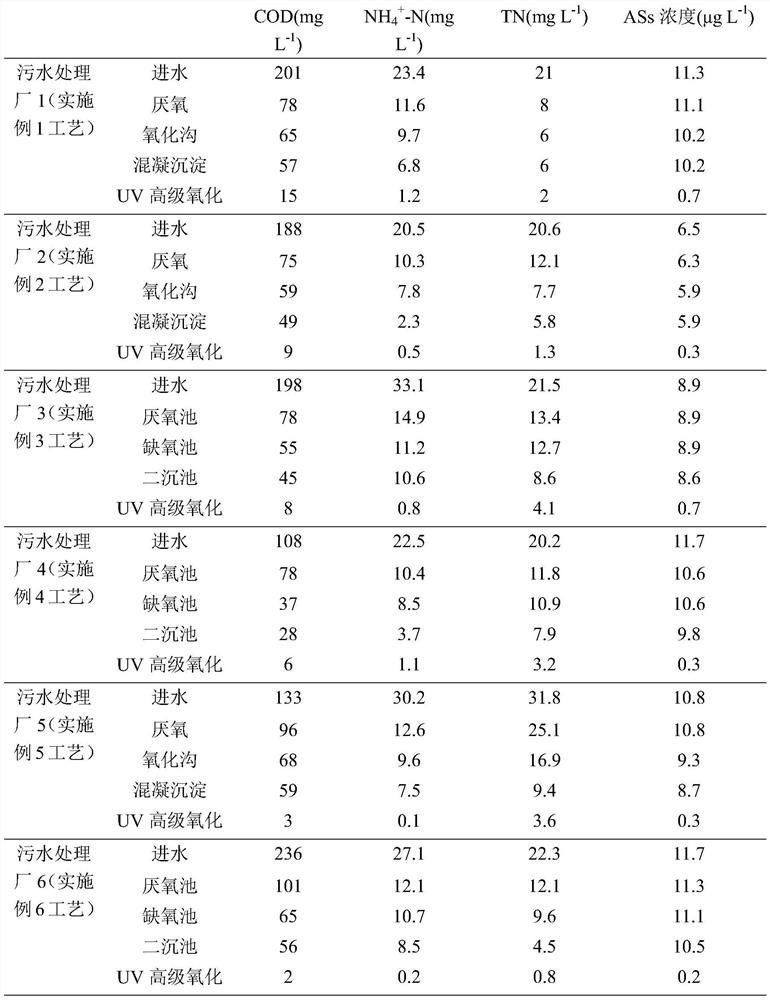

Examples

Embodiment 1

[0020] Embodiment 1: a kind of process based on UV advanced oxidation treatment artificial sweetener wastewater, comprises the following steps:

[0021] Step 1: Preparation of biochar materials

[0022] Take biological materials and use pyrolysis method to prepare biochar materials; biochar materials are specifically made of peanut shells fired at 650 ° C;

[0023] Step 2: Preparation of composite oxide material

[0024] After mixing potassium persulfate and zeolite powder according to the mass ratio of 1.3:10, using a magnetic stirring device to stir, and then baking at 50 ° C for 10 hours to prepare the first mixture; then the biochar material obtained in step 1 Mix with the first mixture according to the mass ratio of 0.7:1, place it in deionized water for 15 minutes of ultrasonic vibration, and then continue to stir at 70°C until the water is evaporated to dryness to obtain a composite oxide material;

[0025] Step 3: Advanced Treatment of Artificial Sweetener Sewage

...

Embodiment 2

[0027] Example 2: Different from Example 1, the specific process of step 3 is: after the wastewater is treated in an anaerobic pool, anoxic pool, aerobic pool, and secondary sedimentation pool; then the waste water is discharged into the inner wall. After entering the reaction tank of a 22W constant power low-pressure mercury lamp, adjust the pH of the wastewater to 3, add 75mg / L NDMP resin to the wastewater, and then add 15mg / L composite oxide material to degrade for 30min.

Embodiment 3

[0028] Embodiment 3: a kind of technology based on the advanced treatment of artificial sweetener wastewater of UV advanced oxidation, comprises the following steps:

[0029] Step 1: Preparation of biochar materials

[0030] Take biological materials and use pyrolysis method to prepare biochar materials; biochar materials are specifically made of peanut shells fired at 500 °C;

[0031] Step 2: Preparation of composite oxide material

[0032] After mixing sodium persulfate and zeolite powder according to the mass ratio of 1.4:10, using a magnetic stirring device to stir, and then baking at 75 ° C for 13 hours to prepare the first mixture; then the biochar material obtained in step 1 and The first mixture was mixed according to the mass ratio of 0.8:1, placed in deionized water and ultrasonically oscillated for 18 minutes, and then continuously stirred at 75°C until the water was evaporated to dryness to obtain a composite oxide material;

[0033] Step 3: Advanced Treatment of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com