High-salinity sewage treatment technology for vegetable products

A technology of high-salt sewage and treatment process, which is applied in water/sewage treatment, biological water/sewage treatment, flotation water/sewage treatment, etc., and can solve the problem of organic matter not being harmlessly treated, polluted, and unsatisfactory effects, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

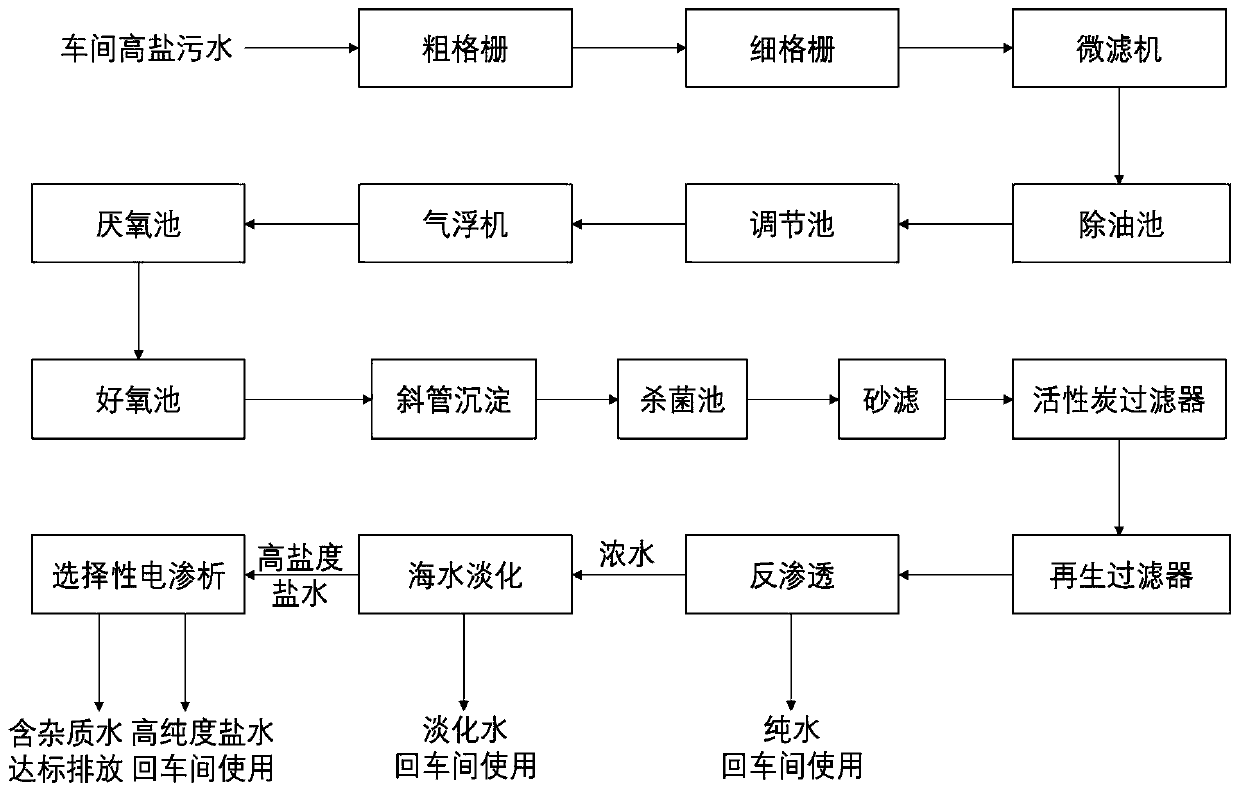

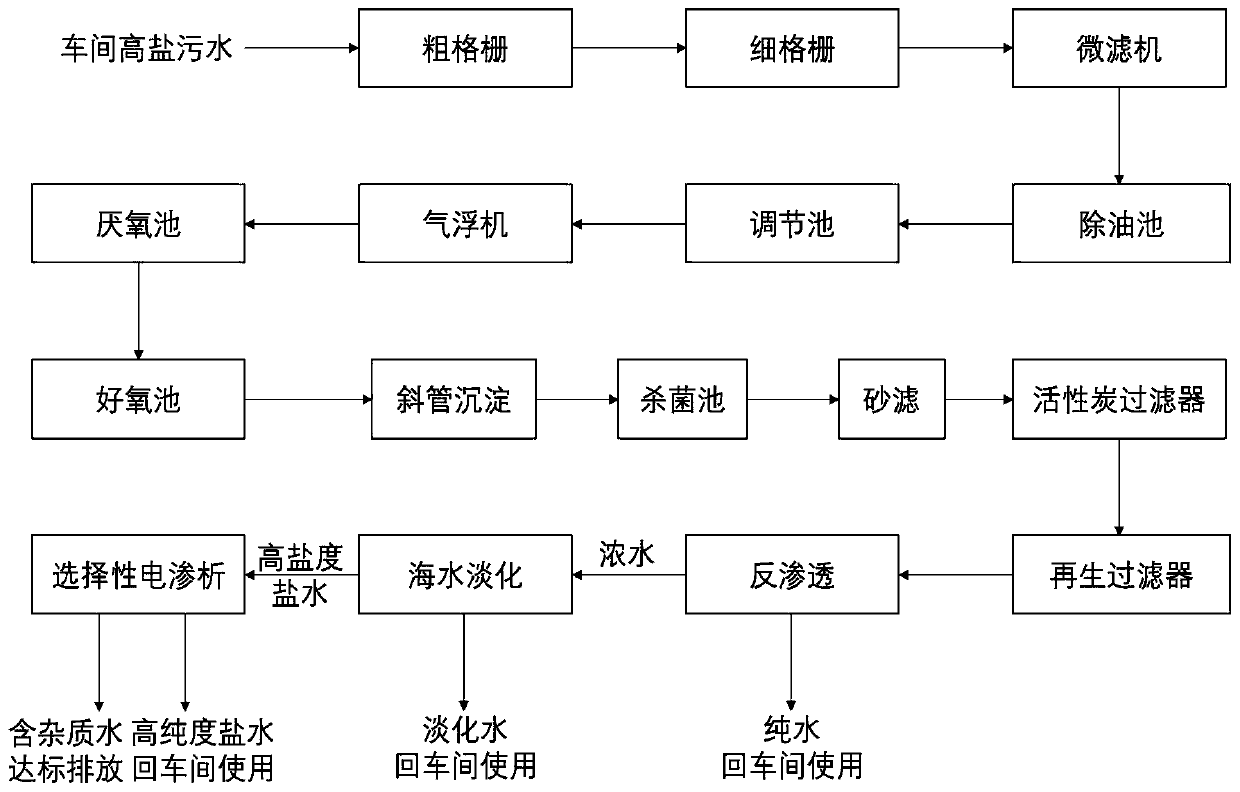

[0021] attached figure 1 It is a process flow diagram of the present invention, and a specific implementation mode is provided, and the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0022] A vegetable product high-salt sewage treatment process, comprising the following steps:

[0023] (1) Filtration and impurity removal: the high-salt sewage from the workshop wastewater discharge outlet is first filtered through coarse and fine grids to remove larger impurities, and then further removed by a microfilter to remove impurities above 20 mesh impurities;

[0024] (2) Degreasing: The high-salt sewage after filtering and removing impurities enters the degreasing tank, and the scraper set in the degreasing tank moves back and forth to scrape off the oil floating on the surface;

[0025] (3) Salinity adjustment: The high-salinity sewage after oil removal enters the salinity adjustment tank for salinity and pH adjustment. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com