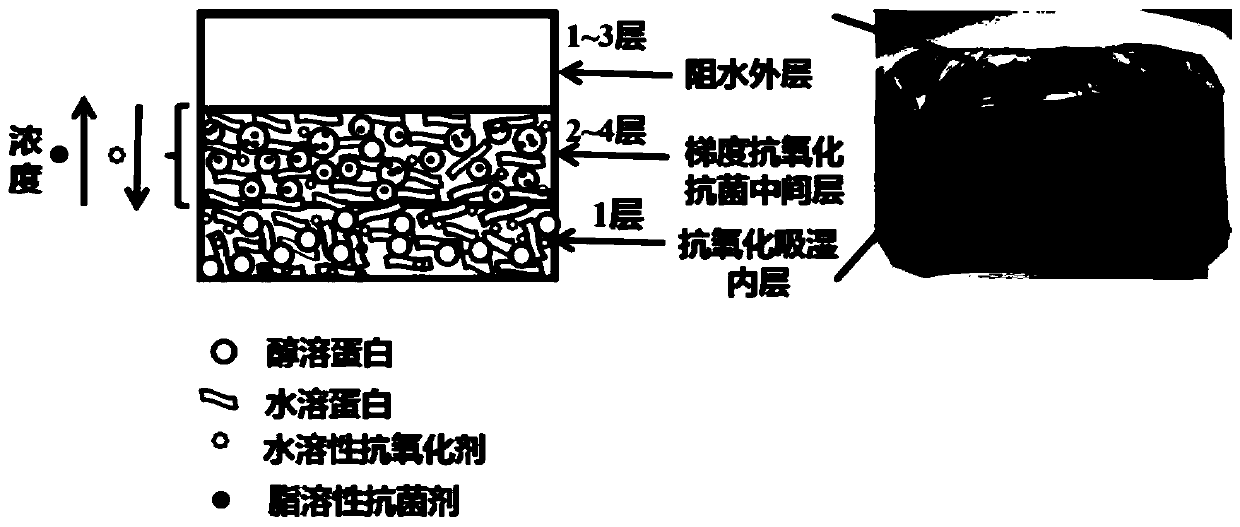

Gradient-slow-release type active composite film and preparing method thereof

A composite film, slow-release technology, applied in the direction of flexible covering, packaging item types, special packaging items, etc. Poor tolerance and other problems, to achieve the effects of excellent adhesion, inhibition of initial oxidative browning, suitable tensile strength and breaking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

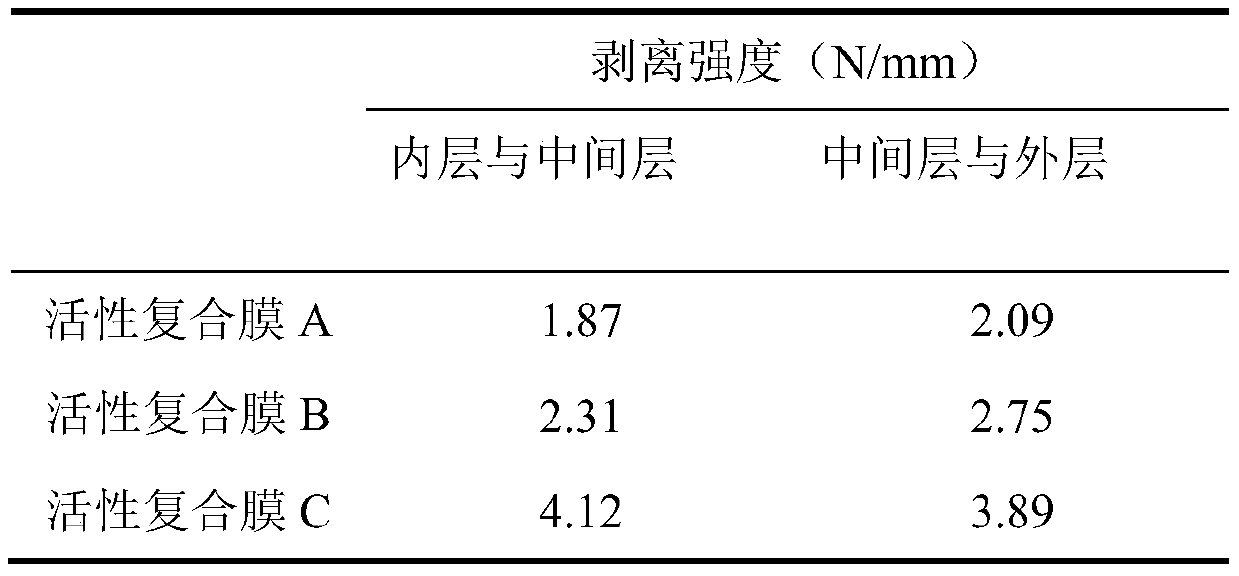

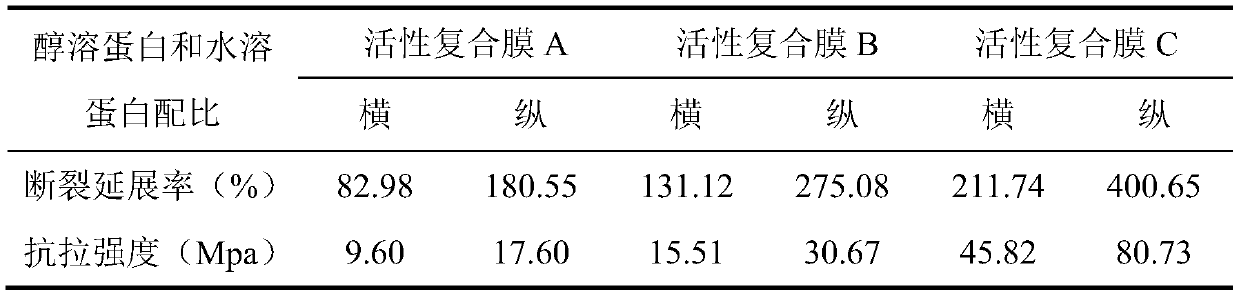

[0047] Embodiment 1 Active Composite Membrane A

[0048] A gradient slow-release active composite film A, prepared by the following steps:

[0049] (1) Preparation of the anti-oxidative moisture-absorbing inner layer stock solution: Dissolve 8g of gelatin and 1.3g of tea polyphenols in 38mL of 80% acetic acid-water solution at 55°C, first fully stir for 0.5h under magnetic stirring conditions; then add 4g For zein, add 0.5g glycerin and fully stir for 2h under the condition of magnetic stirring;

[0050] (2) Preparation of gradient antibacterial and antioxidant intermediate layer stock solution: 4 g of gelatin and different mass fractions of tea polyphenols were dissolved in 20 mL of 80% acetic acid-water solution, 8 g of zein and different mass fractions of rosemary essential oil were dissolved In 18mL of 80% acetic acid-water solution (that is, the mass ratio of prolamin to water-soluble protein in the middle layer is 2:1), first fully stir under magnetic stirring condition...

Embodiment 2

[0053] Embodiment 2 Active Composite Membrane B

[0054] A gradient slow-release active composite membrane B is prepared by the following steps:

[0055] (1) Preparation of the anti-oxidative moisture-absorbing inner layer stock solution: Dissolve 8g of gelatin and 1.3g of tea polyphenols in 38mL of 80% acetic acid-water solution at 55°C, first fully stir for 0.5h under magnetic stirring conditions; then add 4g For zein, add 0.5g glycerin and fully stir for 2h under the condition of magnetic stirring;

[0056] (2) Preparation of gradient antibacterial and antioxidant intermediate layer stock solution: 6g of gelatin and different mass fractions of tea polyphenols were dissolved in 20mL of 80% acetic acid-water solution, 6g of zein and different mass fractions of rosemary essential oil were dissolved In 18mL of 80% acetic acid-water solution (that is, the mass ratio of prolamin to water-soluble protein in the middle layer is 1:1), first stir thoroughly under magnetic stirring c...

Embodiment 3

[0059] Example 3 active composite membrane C

[0060] A gradient slow-release active composite membrane C is prepared by the following steps:

[0061] (1) Preparation of the anti-oxidative moisture-absorbing inner layer stock solution: Dissolve 8g of gelatin and 1.3g of tea polyphenols in 38mL of 80% acetic acid-water solution at 55°C, first fully stir for 0.5h under magnetic stirring conditions; then add 4g For zein, add 0.5g glycerin and fully stir for 2h under the condition of magnetic stirring;

[0062] (2) Preparation of gradient antibacterial and antioxidant intermediate layer stock solution: Dissolve 8g gelatin and tea polyphenols with different mass fractions in 20mL80% acetic acid-water solution, dissolve 4g zein with different mass fractions of rosemary essential oil In 18mL of 80% acetic acid-water solution (i.e. the mass ratio of prolamin to water-soluble protein in the middle layer is 1:2), first fully stir under magnetic stirring conditions for 0.5h; then mix th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com