Lactic acid bacteria powder for relieving heat stress of broilers and application thereof

A technology of heat stress and lactic acid bacteria, applied in the field of microecological preparations for livestock and poultry feeding, and lactic acid bacteria powder, can solve the problem of heat stress broiler production performance, blood indicators and intestinal morphology that have not been reported in the literature by Lactobacillus plantarum P-8 And immune function and other problems, to prevent toxins from invading the body, increase the number of viable bacteria, and improve production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

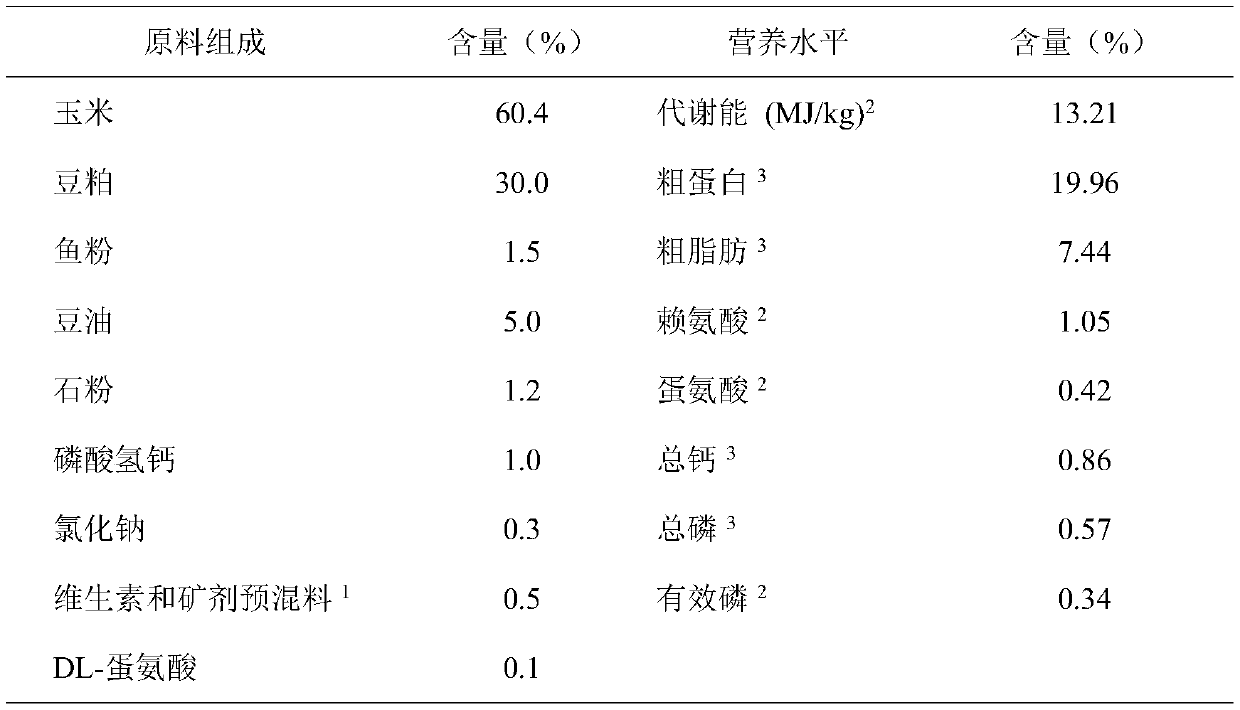

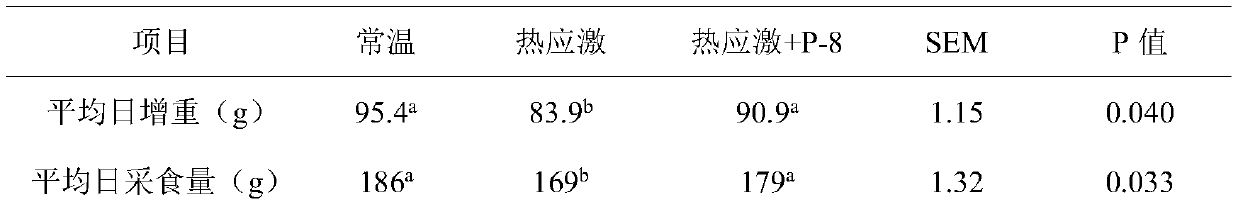

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: the preparation of Lactobacillus plantarum P-8 microecological bacteria powder

[0024] (1) Centrifuge the fermentation broth of Lactobacillus plantarum P-8 at 4000r / min for 20min at 4°C, centrifuge the obtained sludge, wash twice with distilled water, then add 2% (w / w) sorbitol solution to prepare Bacterial suspension, the number of viable bacteria is 2.0×10 12 CFU / mL, spare;

[0025](2) Add the sterilized kaolin into the bacterial suspension according to the mass percentage of 3% (w / w), stir, fully absorb the bacteria for 5 hours, and then pre-cool at -20°C for 12 hours, and then pre-cool the The frozen bacterial agent was put into a vacuum freeze dryer to dry, the freezing temperature was -55°C, the vacuum degree was 5mtorr, and the time was 26h. After the freeze drying was completed, the Lactobacillus plantarum P-8 microecological bacterial powder was obtained. After testing, the number of live bacteria of Lactobacillus plantarum P-8 after rehydratio...

Embodiment 2

[0026] Embodiment 2: the preparation of Lactobacillus plantarum P-8 microecological bacteria powder

[0027] (1) Centrifuge the fermentation broth of Lactobacillus plantarum P-8 at 4000r / min for 20min at 4°C, centrifuge the obtained sludge, wash twice with distilled water, then add 3% (w / w) sorbitol solution to prepare Bacterial suspension, the number of viable bacteria is 2.0×10 12 CFU / mL, spare;

[0028] (2) Add the sterilized kaolin into the bacterial suspension according to the mass percentage of 3.5% (w / w), stir, fully absorb the bacteria for 5 hours, and then pre-cool at -20°C for 12 hours, and then pre-cool the The frozen bacterial agent was put into a vacuum freeze dryer to dry, the freezing temperature was -55°C, the vacuum degree was 5mtorr, and the time was 26h. After the freeze drying was completed, the Lactobacillus plantarum P-8 microecological bacterial powder was obtained. After testing, the number of live bacteria of Lactobacillus plantarum P-8 after rehydra...

Embodiment 3

[0029] Embodiment 3: the preparation of Lactobacillus plantarum P-8 microecological bacteria powder

[0030] (1) Centrifuge the fermentation broth of Lactobacillus plantarum P-8 at 4000r / min for 20min at 4°C, centrifuge the obtained sludge, wash twice with distilled water, then add 3% (w / w) mannitol solution to prepare bacteria Suspension, the number of viable bacteria is 2.0×10 12 CFU / mL, spare;

[0031] (2) Add the sterilized kaolin into the bacterial suspension according to the mass percentage of 3.5% (w / w), stir, fully absorb the bacteria for 5 hours, and then pre-cool at -20°C for 12 hours, and then pre-cool the The frozen bacterial agent was put into a vacuum freeze dryer to dry, the freezing temperature was -55°C, the vacuum degree was 5mtorr, and the time was 26h. After the freeze drying was completed, the Lactobacillus plantarum P-8 microecological bacterial powder was obtained. After testing, the number of live bacteria of Lactobacillus plantarum P-8 after rehydrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com